Squeezing detection control method for consumable electrode arc welding

A technology that consumes electrodes and AC arcs. It is used in arc welding equipment, welding equipment, manufacturing tools, etc. It can solve problems such as reducing welding current, reduce labor and time, stabilize low sputtering control performance, and achieve high-quality welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

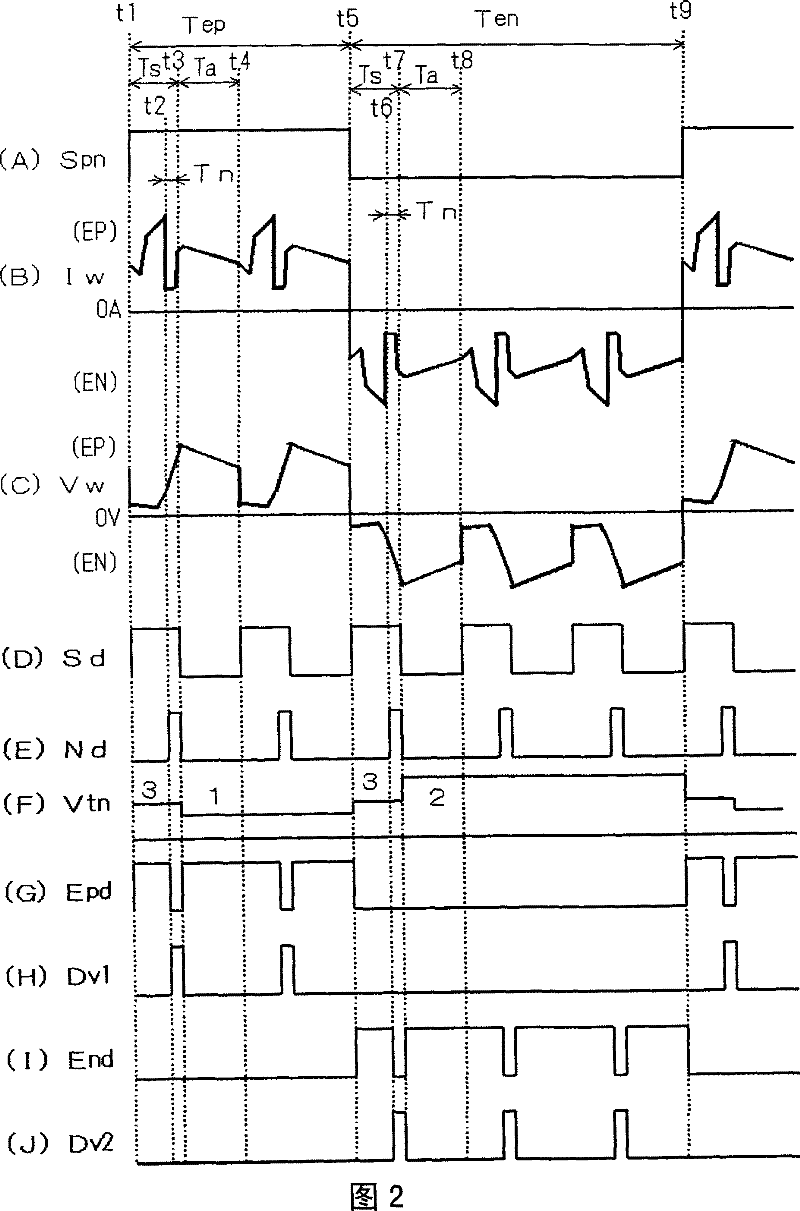

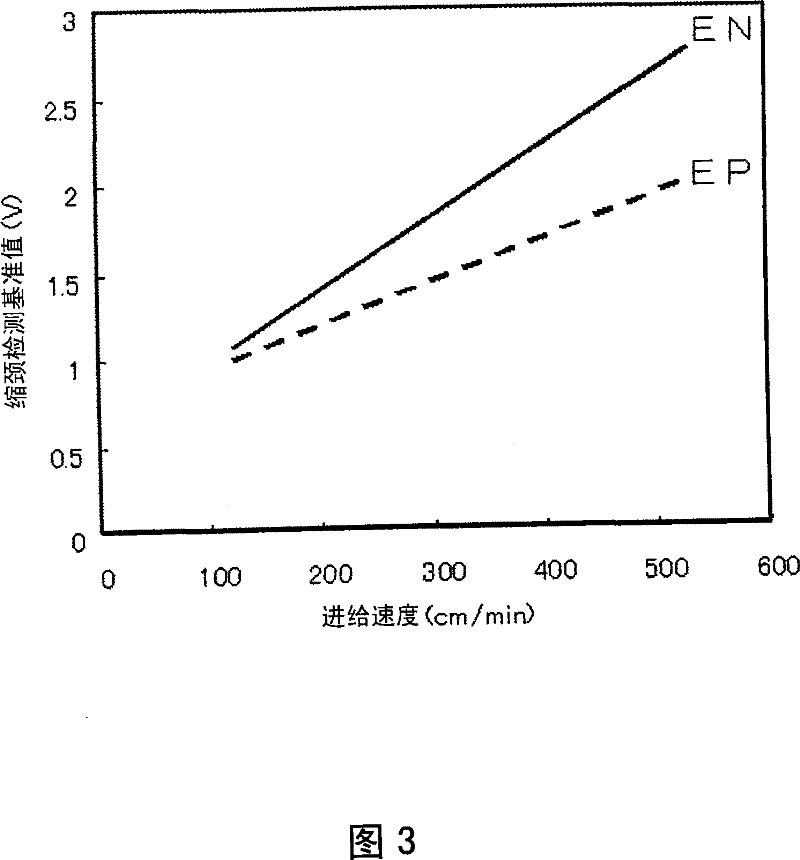

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

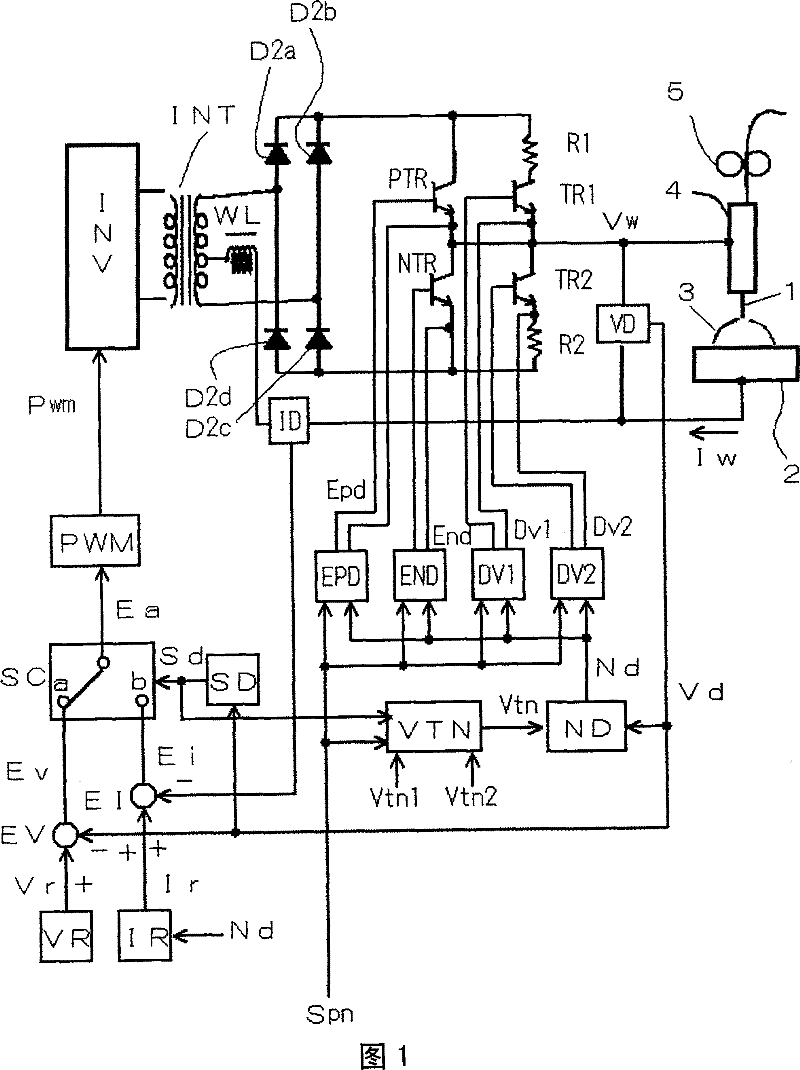

[0044] figure 1 It is a block diagram of a welding power source equipped with a necking detection control method for consumable electrode AC arc welding according to an embodiment of the present invention. Below, refer to figure 1 Each circuit will be described.

[0045] The frequency conversion circuit INV rectifies commercial power such as 3-phase 200V, and performs frequency conversion control according to the pulse amplitude modulation signal Pwm described later, thereby outputting high-frequency AC. The high-frequency transformer INT steps down the high-frequency AC voltage to a voltage suitable for welding. The secondary rectifiers D2a-D2d rectify the stepped-down high-frequency AC, and output positive and negative DC voltages. Reactor WL smoothes this DC voltage.

[0046]The electrode positive polarity switching element PTR and the electrode negative polar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com