Arrangement of a two stage turbocharger system for an internal combustion engine

A technology for internal combustion engines and equipment, applied to mechanical equipment, internal combustion piston engines, charging systems, etc., can solve problems such as heat loss and performance degradation, and achieve the effects of reducing plume flow, reducing manufacturing and assembly costs, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

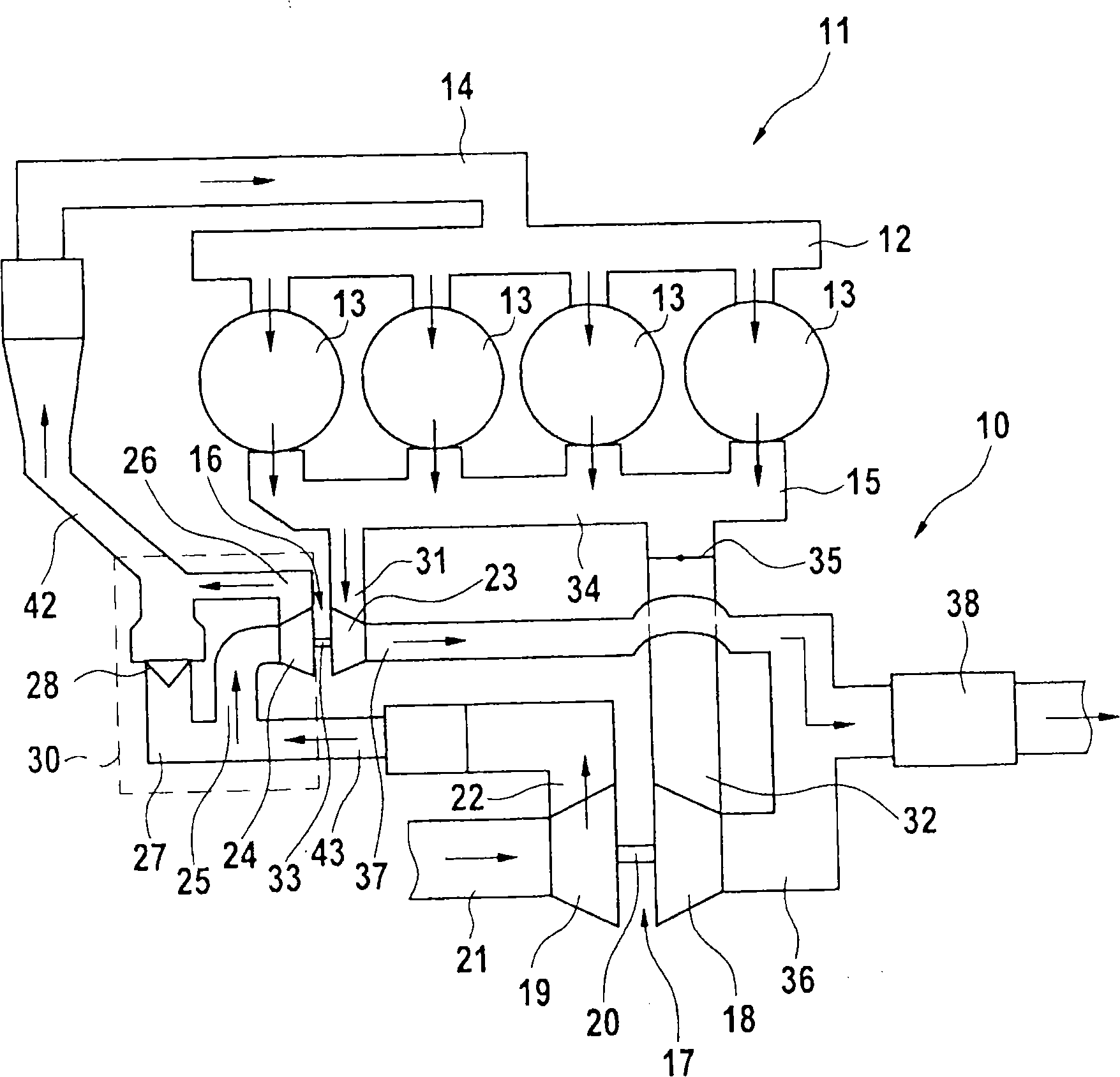

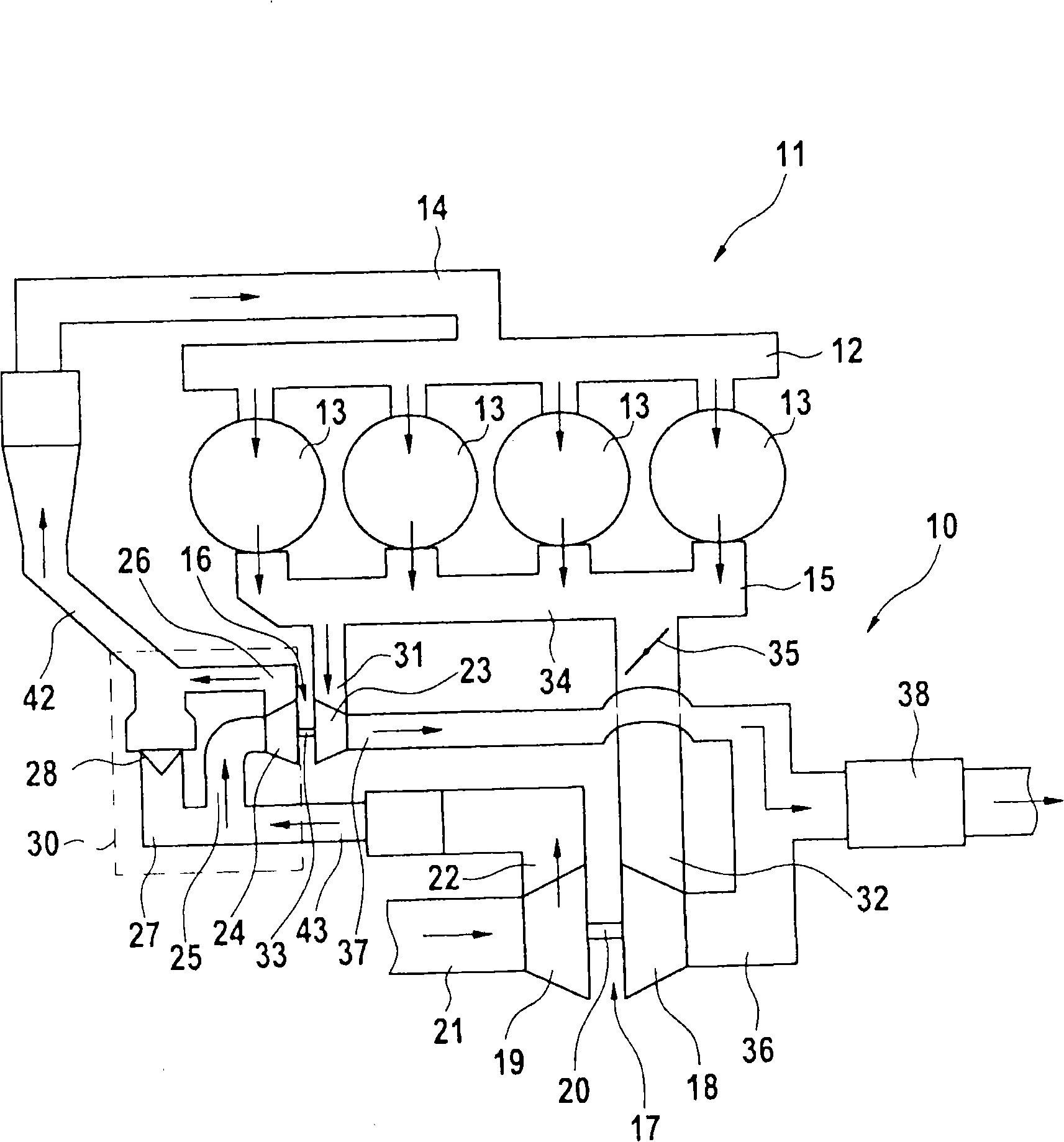

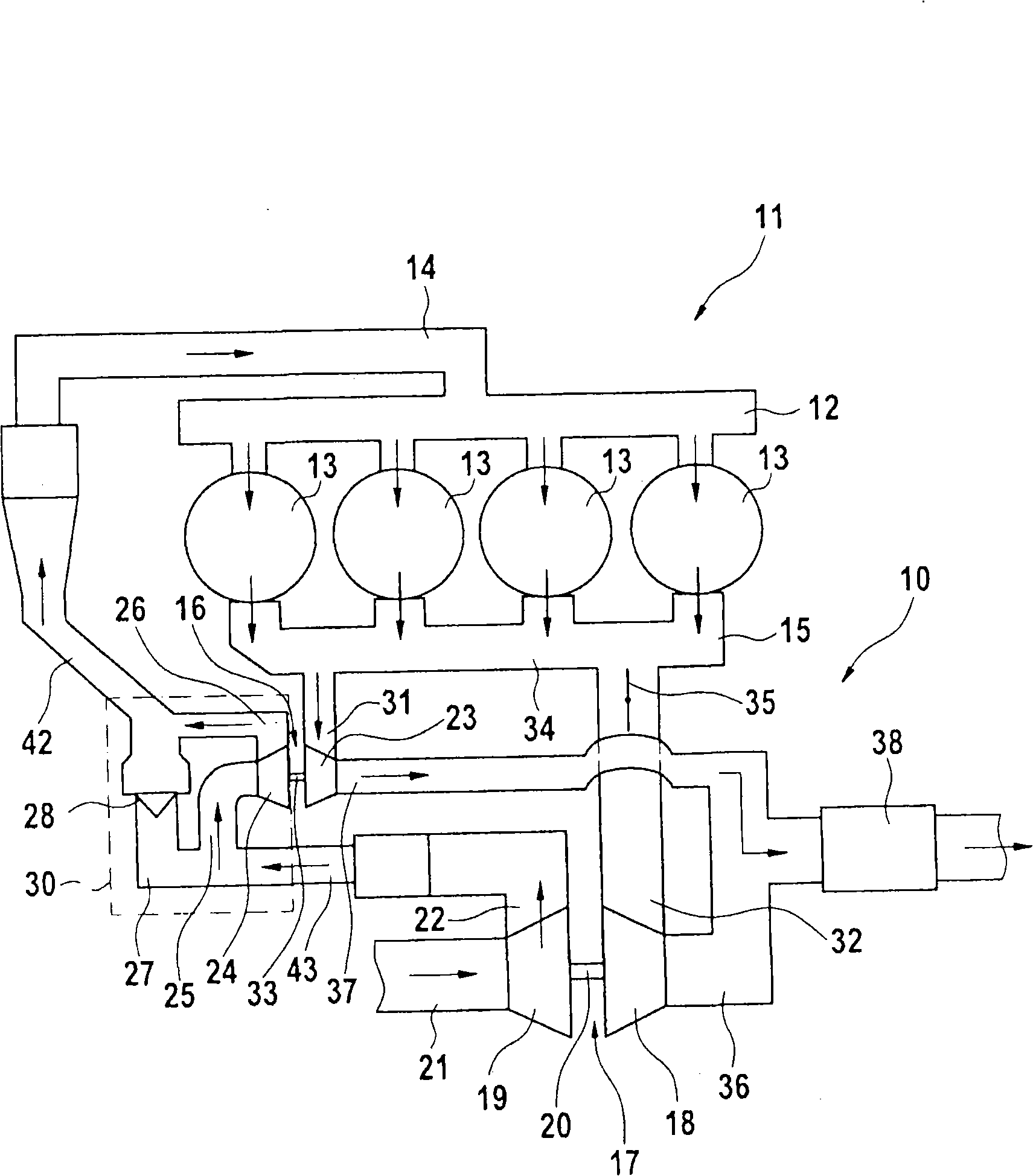

[0051] Figure 1-3 A system diagram showing the operation of the two-stage turbocharger system 10 of the internal combustion engine 11 under three different conditions. FIG. 4 shows the two-stage turbocharger system 10 in three dimensions, and FIGS. 5-7 show the two-stage turbocharger system 10 in cross-section.

[0052] The internal combustion engine 11 includes an engine block 12 with a plurality of cylinders 13 . The engine shown is a compression ignition internal combustion engine, such as a diesel engine. However, the described two-stage turbocharger system is not limited to use in diesel engines, for example it can also be used in engines burning fuels such as gasoline, ethanol and gasoline-ethanol mixtures. Cylinder 13 receives pressurized fuel from a fuel supply in known manner. The internal combustion engine 11 includes an intake manifold 14 and an exhaust manifold 15 . The internal combustion engine 11 is a turbocharged engine comprising a two-stage turbocharging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com