Hydraulic support tail beam

A technology of hydraulic support and tail beam, applied in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems of inappropriate light support, large clearance of tail beam, increase the cost per ton of coal, etc. It is difficult to adjust the rack and reduce the effect of reducing the cost per ton of coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

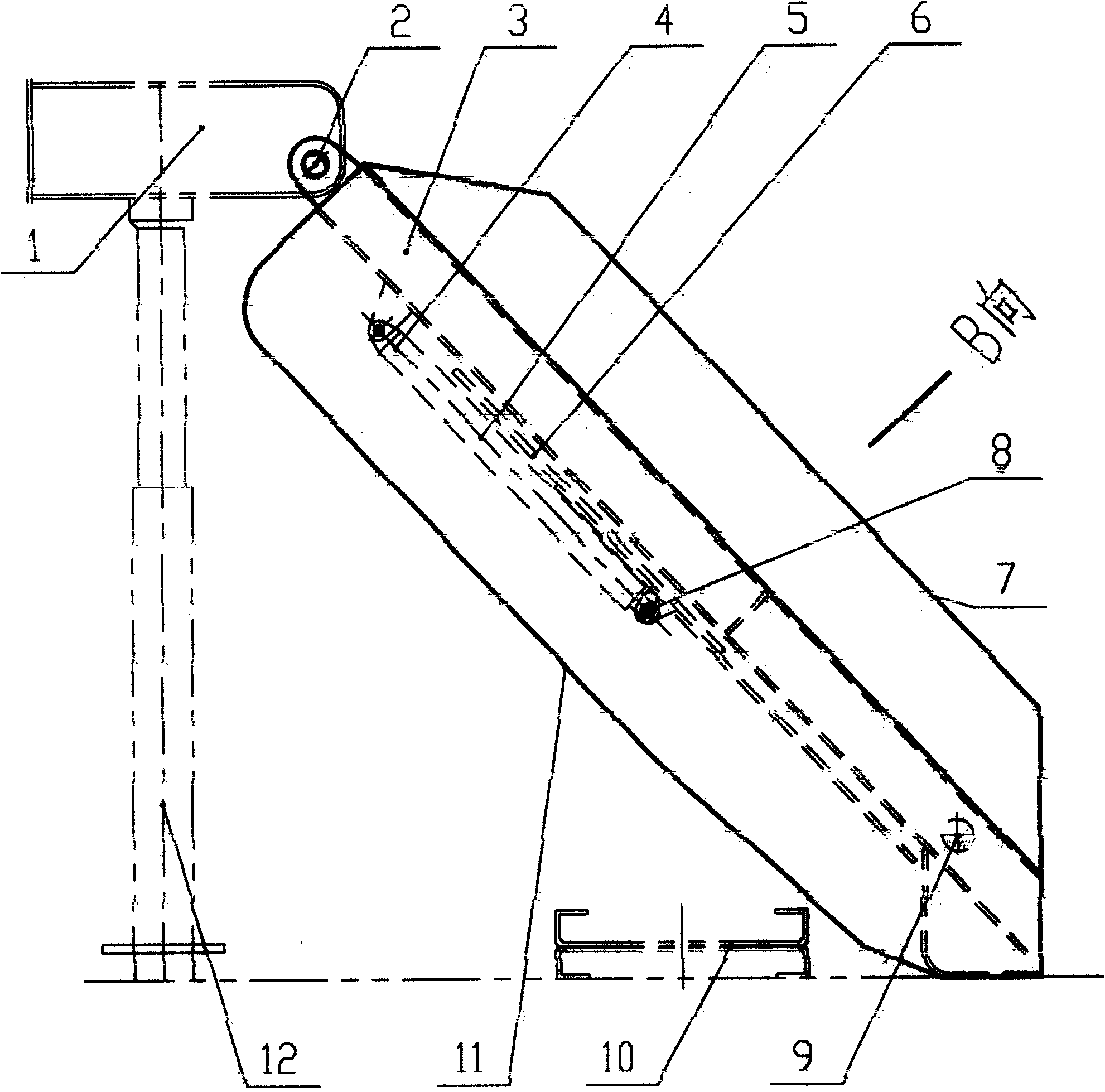

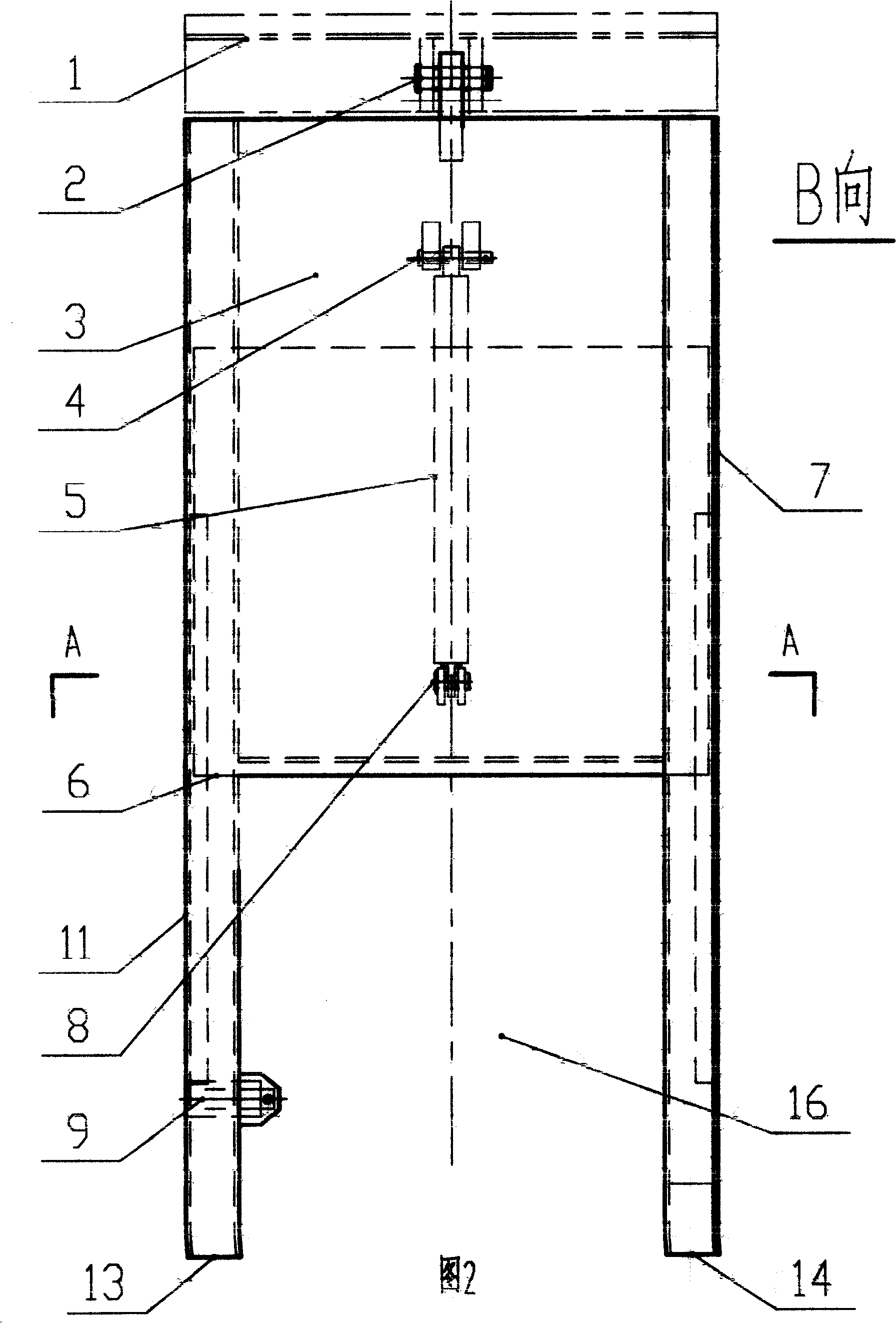

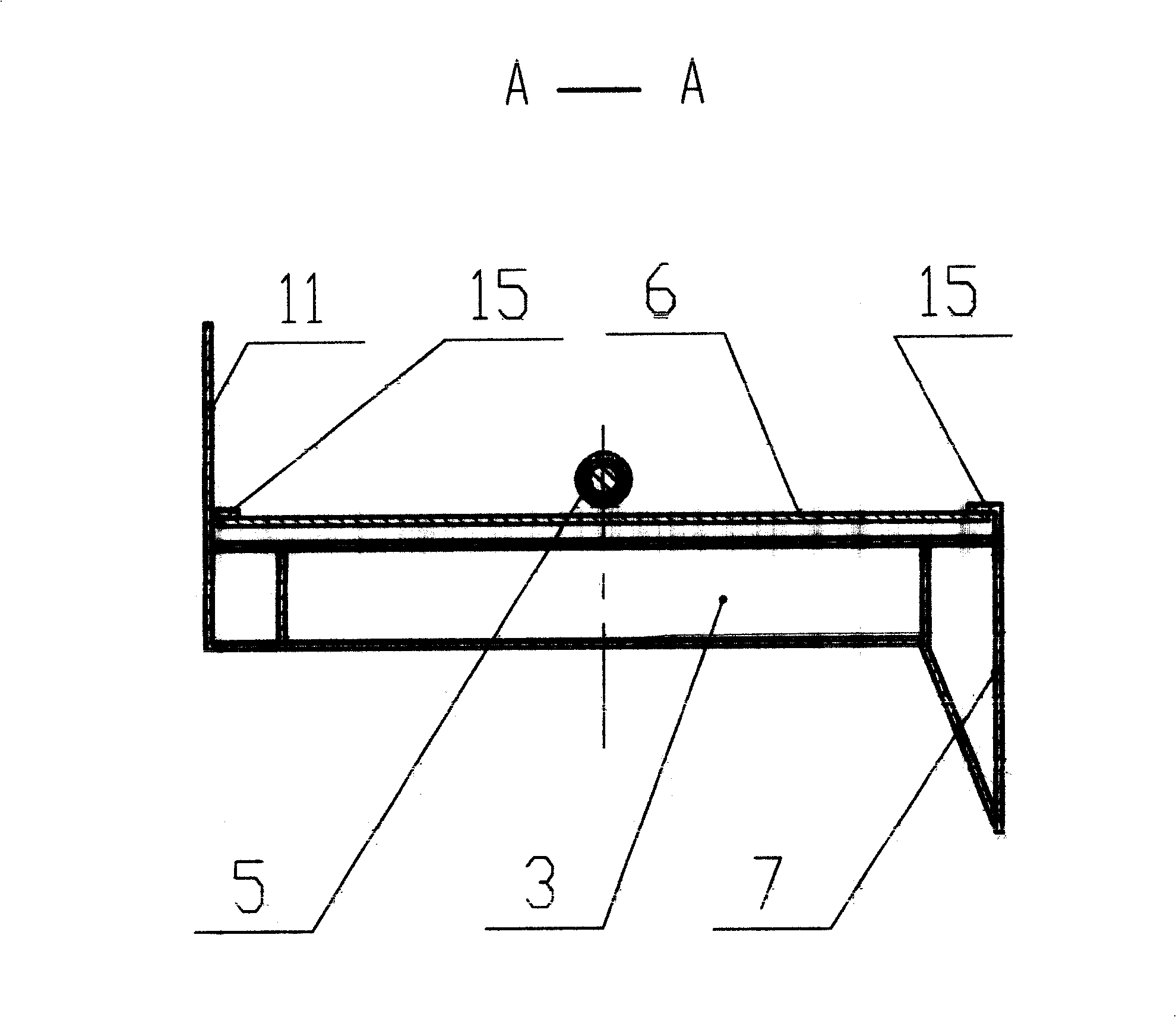

[0012] figure 1 A front view of a tail boom for a hydraulic support of the present invention is given when the hydraulic support is installed together. Including bracket 1, hinge 2 at the rear of the bracket and the upper part of the tail beam, tail beam 3, kerosene cylinder 5, coal discharge gate 6, hinge 4 connecting the kerosene cylinder 5 and tail beam 3, connecting the kerosene cylinder 5 and the discharger The hinge 8 of the coal gate 6 is adjusted to the oil cylinder 9.

[0013] Combine below figure 1 , Figure 2 and image 3 Describe the action sequence of a tail beam for a hydraulic support of the present invention when used in a coal mining face: when used at a working face, a tail beam for a hydraulic support of the present invention is installed at the rear of the support 1 through a unique hinge 2, and its lower end The end faces 13 and 14 are supported on the bottom plate and densely arranged in a horizontal row to block the top coal and gangue on the upper sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com