Full-automatic liquid filling machine

A fully automatic soup-filling technology, which is applied in the safety/control of bottle capping machines, flanged bottle caps, capping under vacuum, etc., can solve the problem of less food and beverage fields, and achieve high degree of automation, simple structure, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

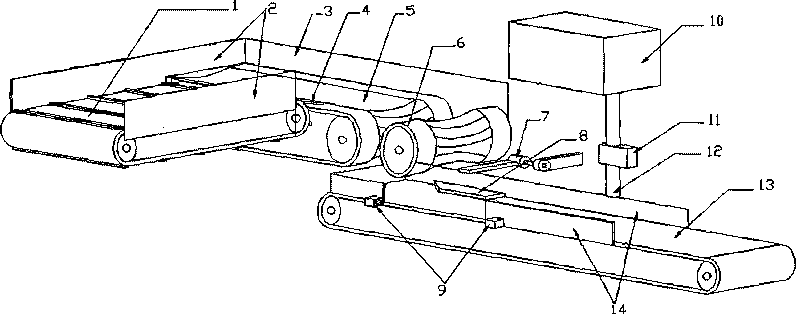

[0019] Such as figure 1 , 2 As shown in , 3, the fully automatic soup filling machine includes an automatic separation device for a single pile of bowls, an automatic separation device for a single bowl, an automatic detection and removal device for turning over bowls, and an automatic filling device for soup, wherein:

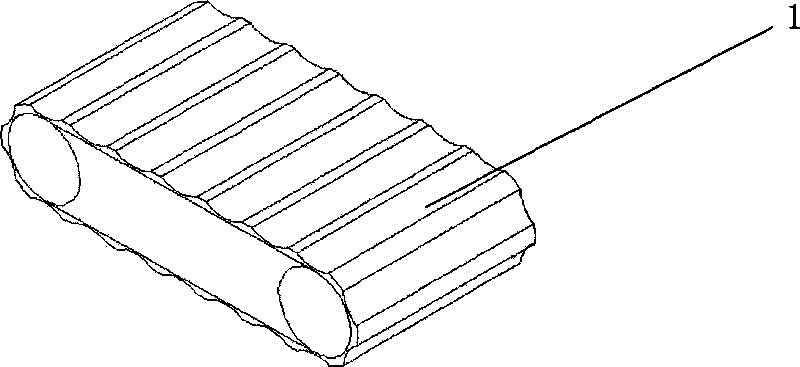

[0020] 1) Automatic separation device for a single pile of bowls: on the surface of the first conveyor belt, there are arc grooves that are equally distributed and can stack a pile of bowls. The arc grooves are perpendicular to the first conveyor belt, and the first conveyor belt is installed on the The first pair of rollers are driven to rotate by a stepper motor (not shown in the figure);

[0021] 2) Automatic separation device for a single bowl: an arc groove is provided on the surface of the second conveyor belt, the arc groove is parallel to the second conveyor belt, and a series of arc-shaped convex lines are arranged on the surface of the arc groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com