Method for manufacturing machine-made egg

A manufacturing method and mechanism technology, applied in food preparation, food forming, food coating, etc., can solve problems affecting the freshness and tenderness of products, achieve balanced production, reduce production costs, and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

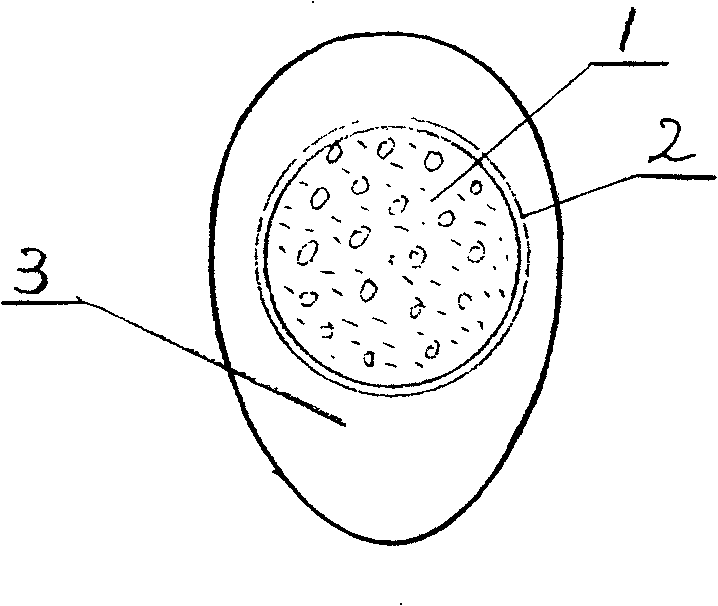

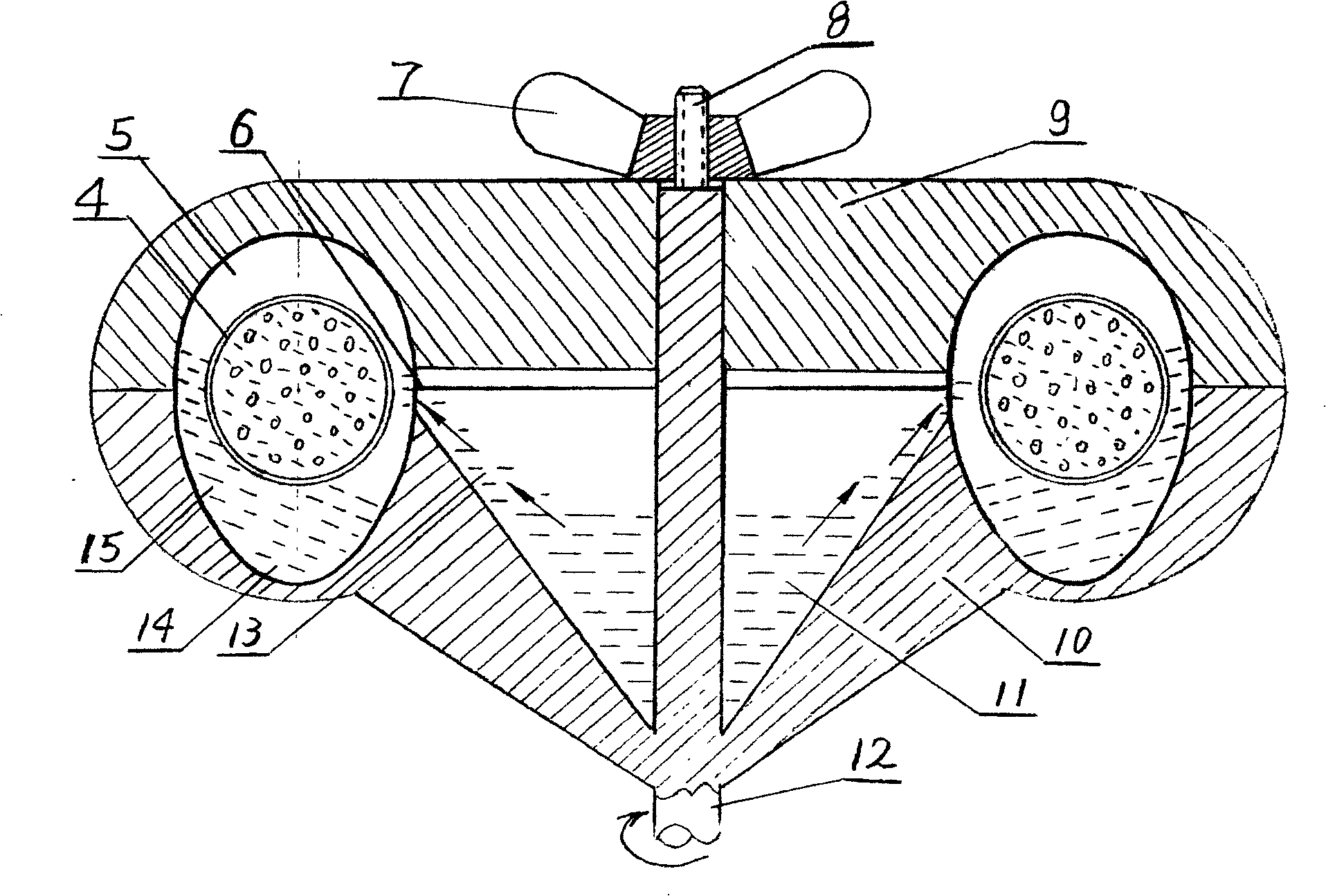

[0013] Refer to the attached picture, the raw material of the machine-made egg yolk pill 1 can be seasoned rice, meat-based pre-prepared dishes, vegetarian-based pre-prepared dishes, and meat-vegetable pre-prepared dishes, etc. The pill, the machine-made egg yolk pill is hardened through the freezing process. Then, paste on the outside of the frozen egg yolk pellets 1 to form the sealing layer 2, and then fast-fry the sealing layer 2 to reach the strength required by the design and prevent adhesion. In this way, a machine-made egg yolk pill 1 with a hard inside that meets the requirements of the formula is manufactured, and a machine-made egg yolk 4 with a sealing layer 2 that meets the design requirements on the outside is manufactured.

[0014] Open the upper mold 9 of the forming machine and the lower mold 10 of the forming machine, and then put the machine-made egg yolk 4 or the frozen machine-made egg yolk pellet 1 into the lower part of the egg-shaped cavity 14, and then put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com