Method for aligning rod bundle checkout sample

A technology for inspecting samples and wire rods, which is applied in the field of physical and chemical inspection, can solve the problems of flatness of samples, poor flatness of samples, and high labor intensity, etc., and achieves good straightening effect, small impact, and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

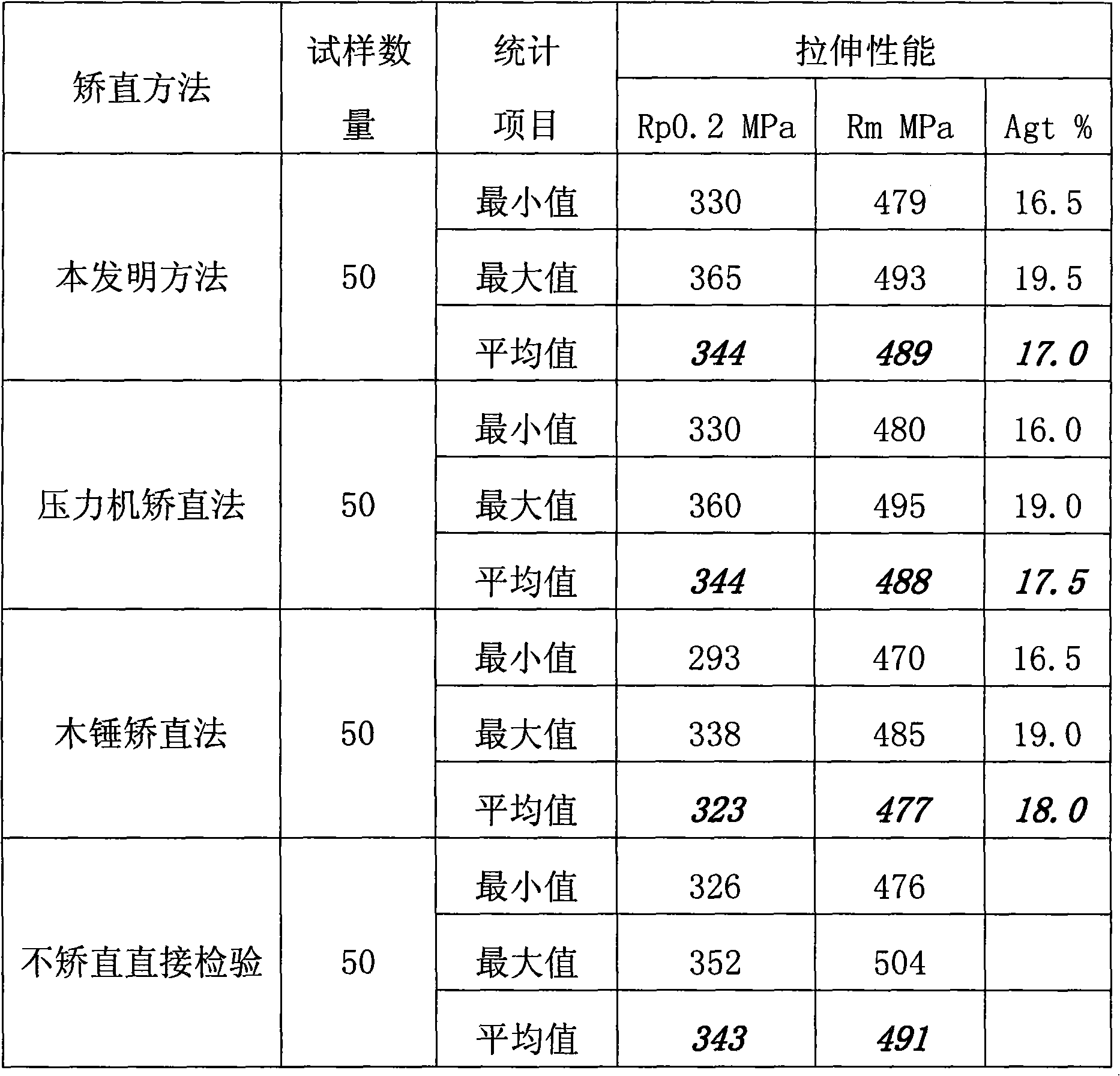

[0009] Choose the low-carbon steel wire rod of φ 9mm, test the tensile properties after straightening according to the method of the present invention, and the test results are shown in Table 1. Table 1 also lists the tensile performance test results of the samples straightened by wooden hammer, straightened by press and directly tested without straightening. As can be seen from Table 1, the inventive method and the press straightening method have very little influence on the strength test result after straightening, which is very close to the strength of the direct inspection sample without straightening. The strength test result of wooden hammer straightening method is low. This is because the deformation of the sample section is uneven when using wooden hammer straightening. For the section that has local plastic deformation but has not entered the hardening stage, it is equivalent to reducing the transverse The cross-sectional area makes the measured yield stress Rp0.2 low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com