Take-up winder with protecting cover

A technology for a protective cover and a wire drawing machine, which is applied in the field of wire drawing machines, can solve problems such as fire hazards and easy wire breakage, and achieve the effect of reducing the possibility of fire and not easily breaking wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

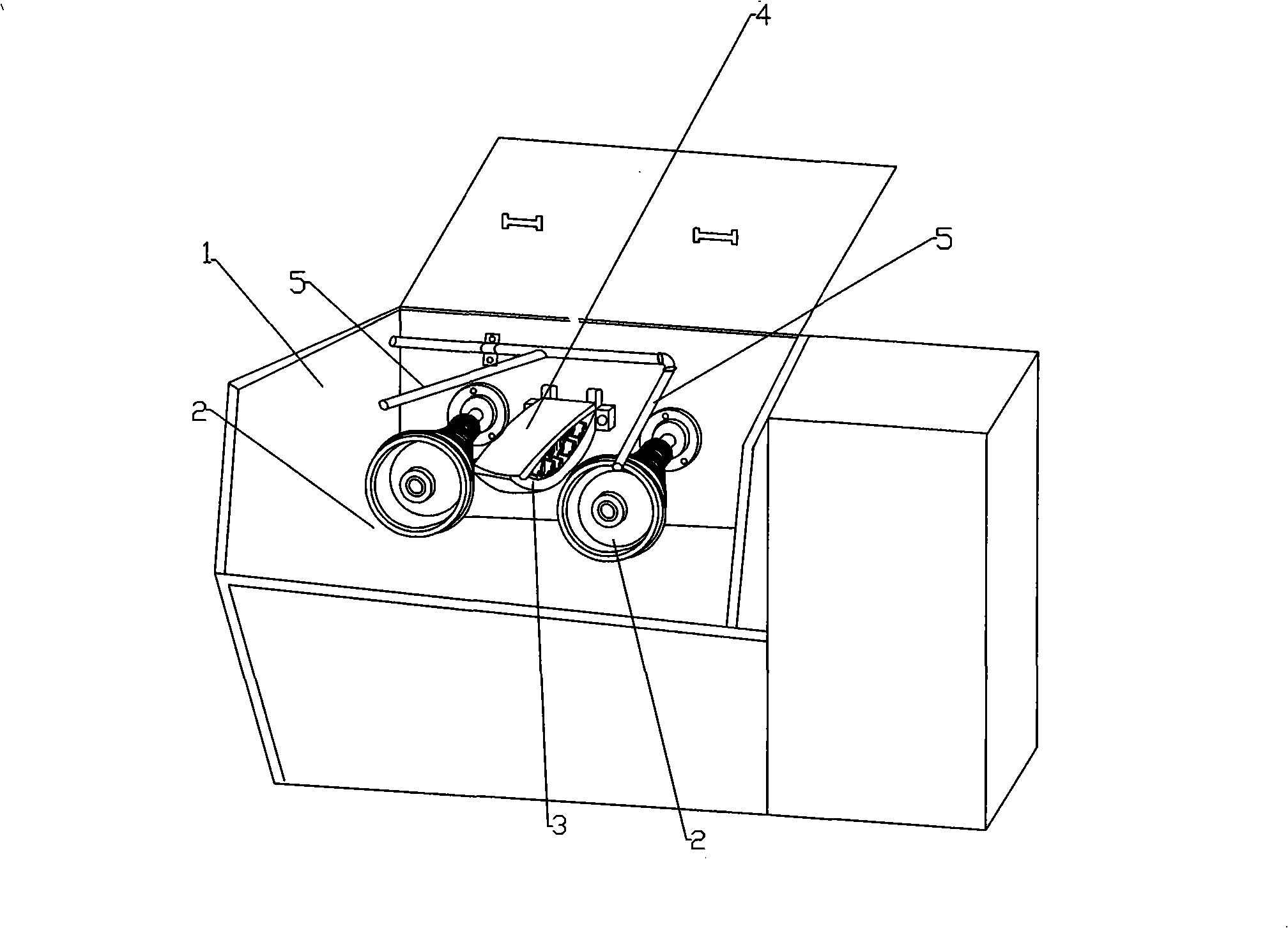

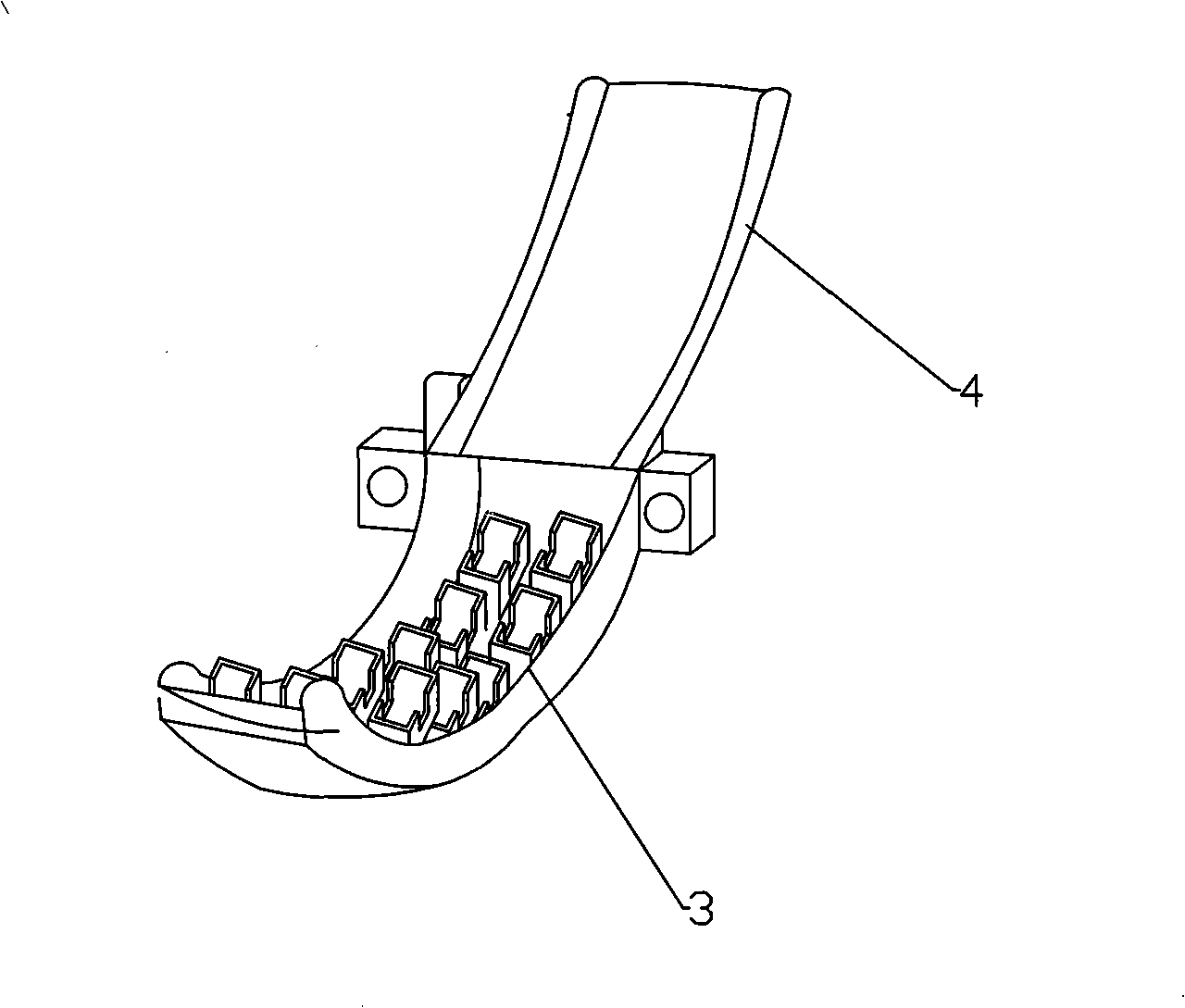

[0011] see Figure 1-2 : A wire drawing machine with a protective cover, including a body 1, a transmission mechanism, a wire drawing mechanism, a wire winding mechanism, a cooling lubricating device and an electrical control system, each group of wire drawing mechanisms includes two tower pulleys 2 and a mold base 3, the mold The frame 3 is arranged between the two tower pulleys 2, and the drawing die is installed on the mold frame 2; the protective cover 4 matched with the mold frame 2 is installed above the mold frame 2, and the protective cover 4 is connected with the mold frame 2. Between the frames 2 there are openings for the metal wires before and after passing through the mold to pass through, and the nozzles of the nozzles 5 of the cooling and lubricating device are aimed at the two cone wheels 2 on both sides of the mold frame.

[0012] By installing the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com