Construction method of inverse force wall and inverse force dado

A construction method and technology of reaction force pedestal, which are applied in the preparation of test samples, the testing of machine/structural components, material inspection products, etc., can solve the problems of loading hole displacement, welding fixing error, affecting accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

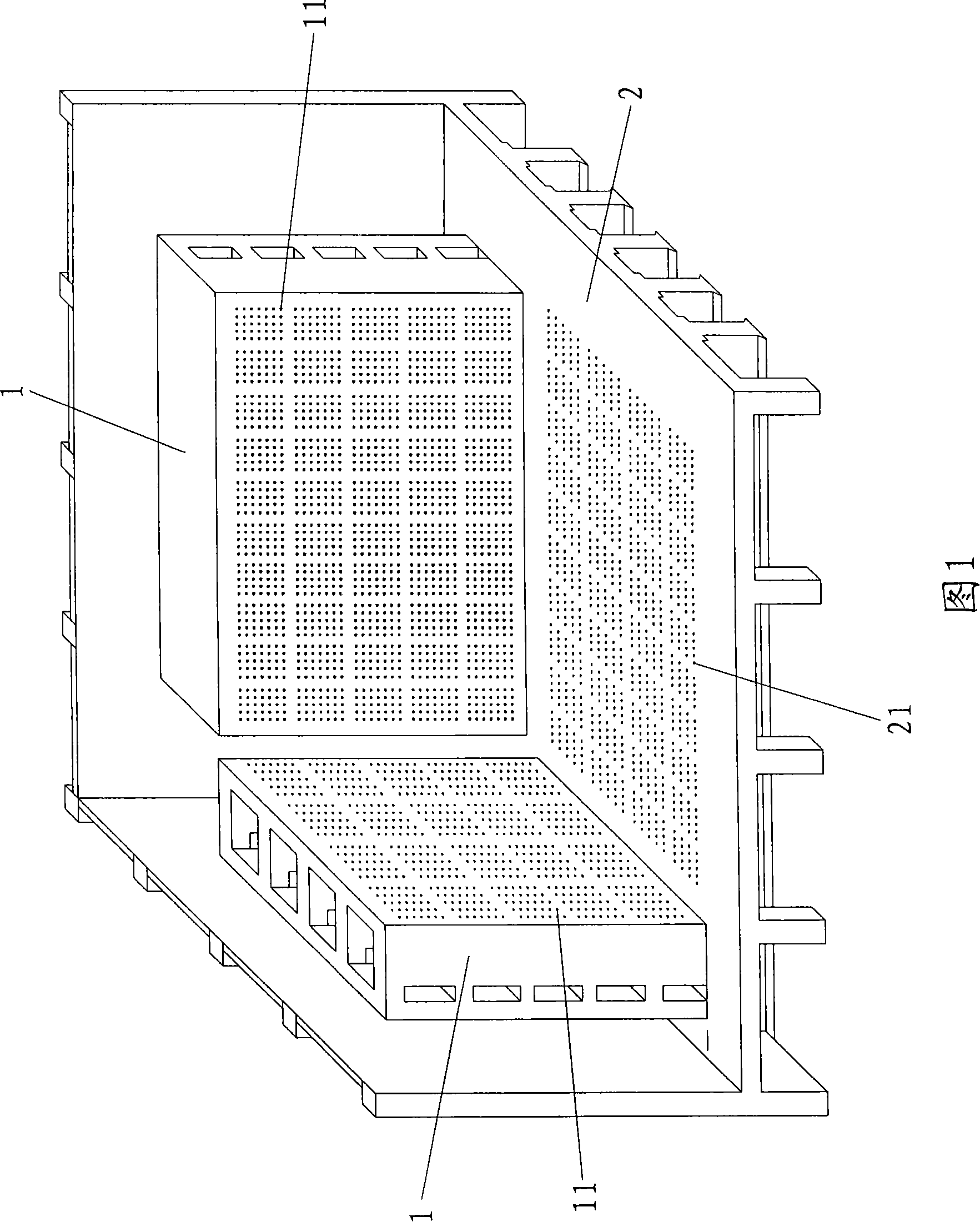

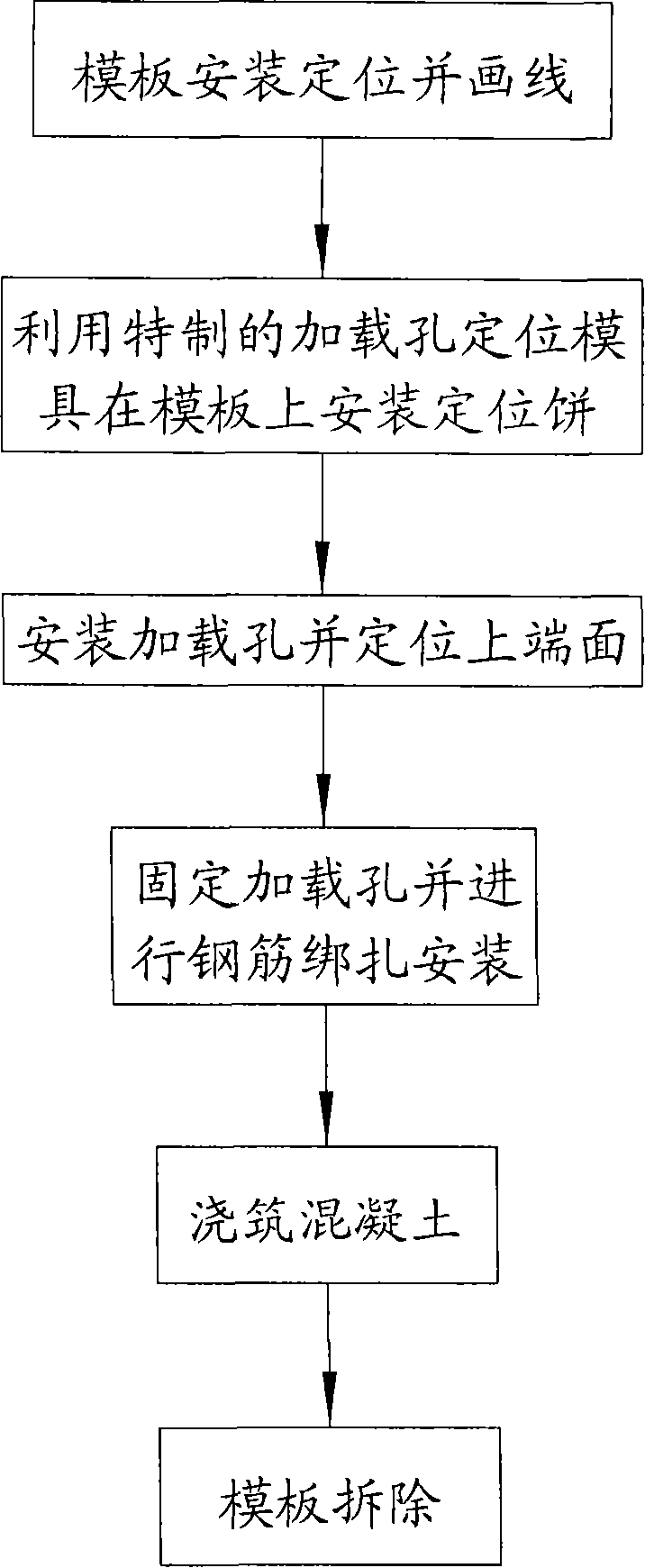

[0041] Such as figure 2 As shown in Fig. 1, the main construction process of the reaction pedestal of the present invention is as follows: formwork installation and positioning and line drawing - using a special loading hole positioning mold to install positioning cakes on the formwork - installing loading holes and positioning Upper end surface - fix the loading hole and install the steel bar binding - pour concrete - remove the formwork. The specific instructions are as follows:

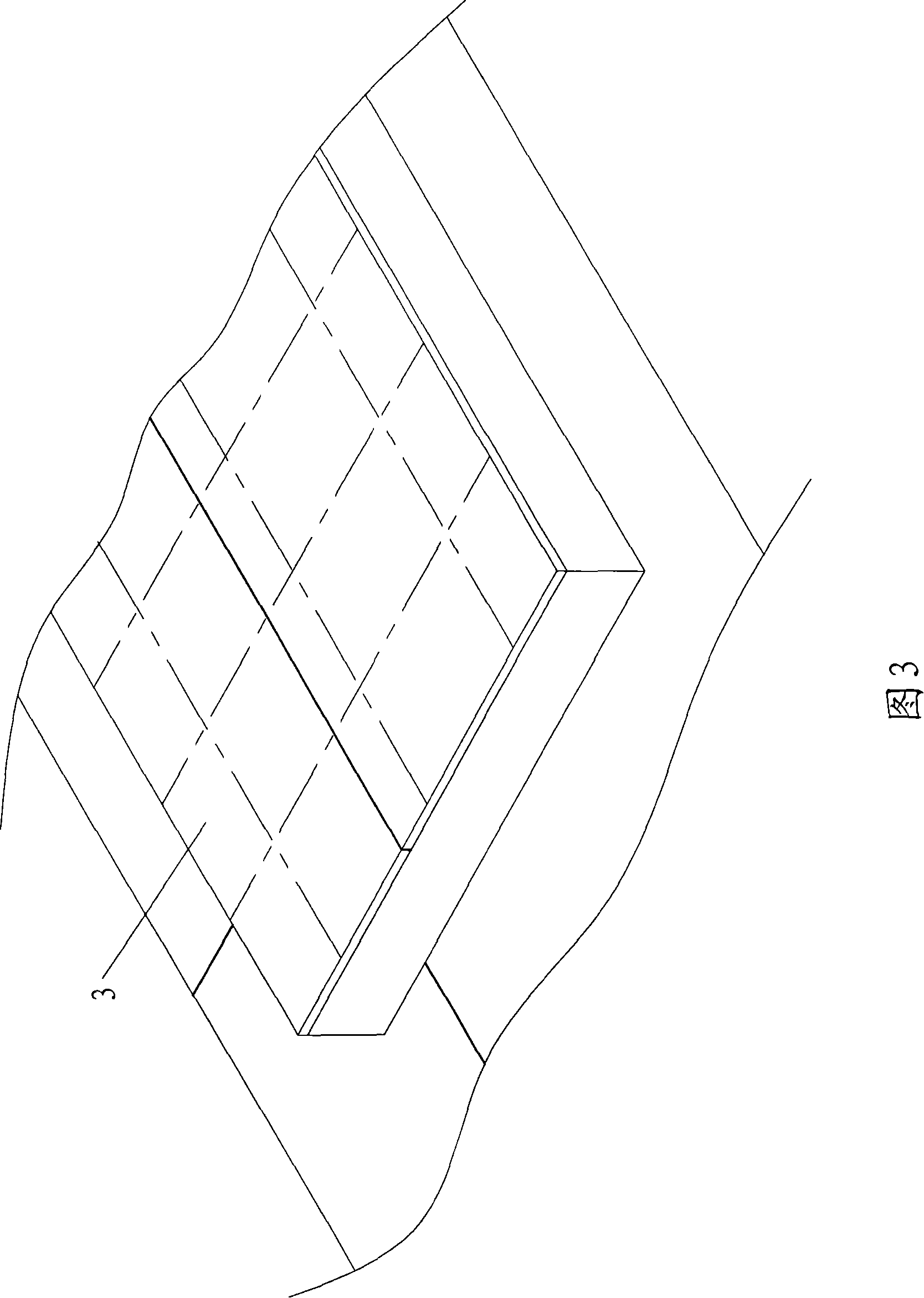

[0042] 1. Template installation, positioning and drawing lines (as shown in Figure 3):

[0043] Install the fixed template 3, and utilize the support system (not shown) to support the template 3; then control the surface flatness of the template 3, and the flatness of the template 3 directly determines the flatness of the lower surface of the counter force pedestal 2 , which is also the premise to ensure the flatness of the upper surface of the counter force pedestal 2; then draw vertical and hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com