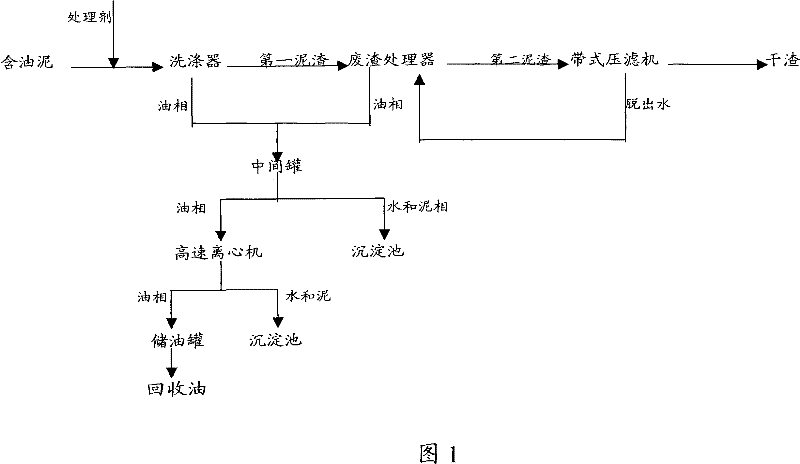

Method and system for processing oil-containing sludge

A treatment agent and processor technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of waste of resources, environmental pollution of accumulation sites, etc., to eliminate pollution sources and reduce pollution intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

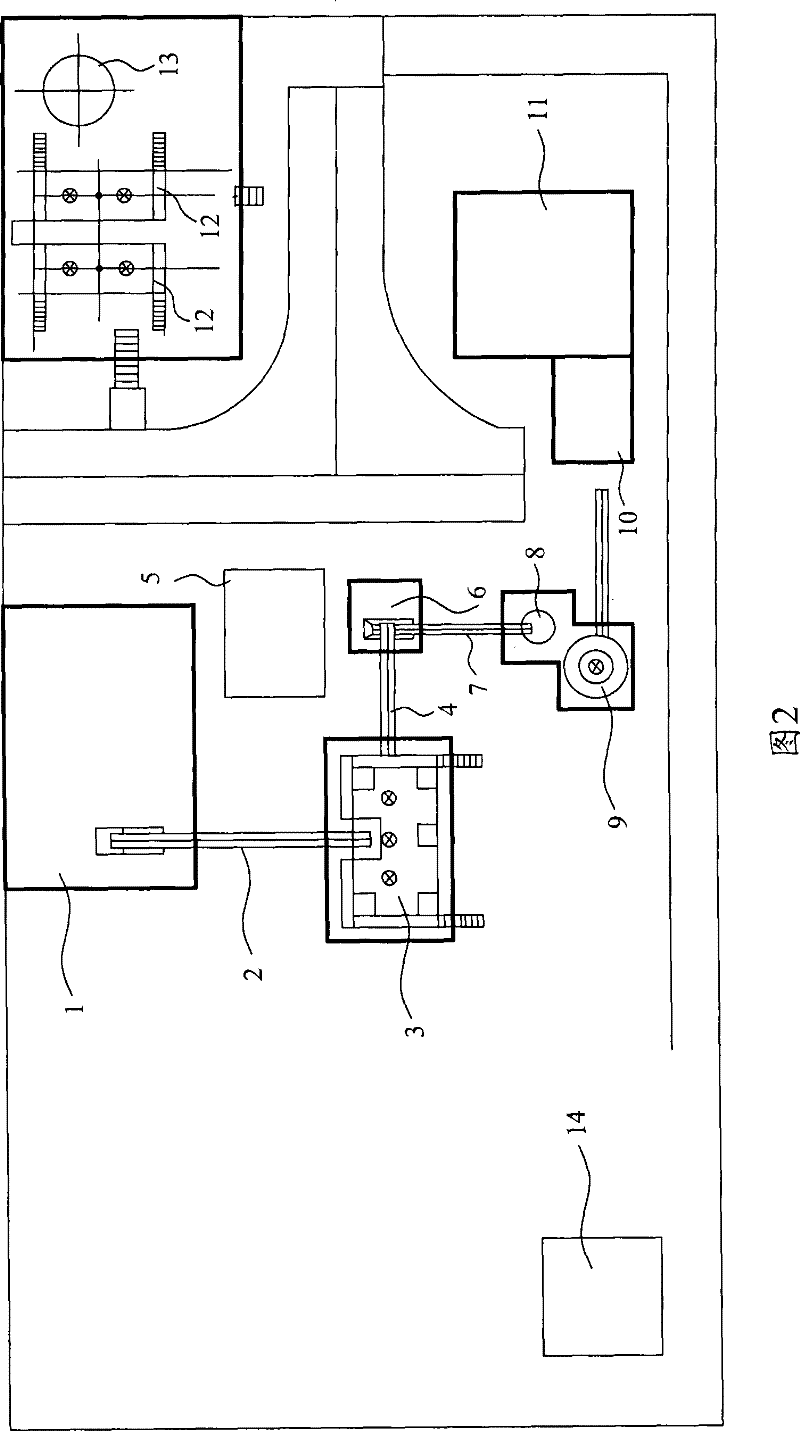

Examples

Embodiment 1

[0063] The oil-containing sludge with an oil content of 12.% is continuously sent to the solvent scrubber 3 from the raw material stockyard 1 through the first belt conveyor 2 at a speed of 3 tons / hour, and about 10 tons of oil-containing sludge and about 10 tons of of water, and add 120 kg of treatment agent, put into an appropriate amount of treatment agent every day in operation, to maintain the content of the treatment agent at the level of about 0.1% of the weight of the sludge, the treatment agent is made according to the following ratio: 5 parts by weight of silicon Magnesium acid, 8 parts by weight of sodium phosphate, 5 to 10 parts by weight of polyacrylamide, and 5 parts by weight of sodium dodecylsulfonate. The temperature of the scrubber is kept at 65-85°C with continuous stirring. The oil phase in the upper layer flows into the intermediate tank, and the first sludge in the lower layer is scraped off by a slag remover (not shown) from the bottom of the scrubber, f...

Embodiment 2

[0065] The oily sludge with an oil content of 18% is continuously sent to the solvent scrubber at a speed of 2.5 tons per hour from the raw material stockyard through the first belt conveyor, and about 8 tons of oily sludge and about 12 tons of water are injected at the beginning of the operation. And add 160 kilograms of treatment agent, drop into appropriate treatment agent every day in operation, account for the level of about 0.2% of the weight of sludge to maintain the content of treatment agent, this treatment agent is made by following proportioning: 3 parts by weight of silicic acid Magnesium, 5 parts by weight of sodium phosphate, 5-10 parts by weight of polyacrylamide, and 3-5 parts by weight of sodium dodecylsulfonate. The temperature of the scrubber is kept at 65-85°C with continuous stirring. The oil phase in the upper layer flows into the intermediate tank, and the first sludge in the lower layer is scraped from the bottom of the scrubber by the slag remover, flo...

Embodiment 3

[0067]The oily sludge with an oil content of 23% is continuously sent from the raw material stockyard to the solvent scrubber at a speed of 2 tons per hour through the first belt conveyor, and about 6 tons of oily sludge and about 14 tons of water are injected at the beginning of the operation. And add 240 kg of treatment agent, put in an appropriate amount of treatment agent every day during operation, to maintain the content of treatment agent at the level of about 0.1, 0.2, 0.4, 0.8% of the weight of sludge. The treatment agent is prepared from the following proportions: 5 parts by weight of magnesium silicate, 11 parts by weight of sodium phosphate, 10 parts by weight of polyacrylamide, and 3 parts by weight of sodium dodecylsulfonate. The temperature of the scrubber is kept at 65-85°C with continuous stirring. The oil phase in the upper layer flows into the intermediate tank, and the first sludge in the lower layer is scraped from the bottom of the scrubber by the slag re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com