Sanitary napkin clad diverter and orientation diversion method

A technology for diverters and sanitary napkins, which is applied to cardboard items, etc., can solve the problems of insufficient air suction, poor applicability, and high manufacturing cost, and achieve the effects of solving insufficient negative pressure air suction, novel structural design, and ensuring reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

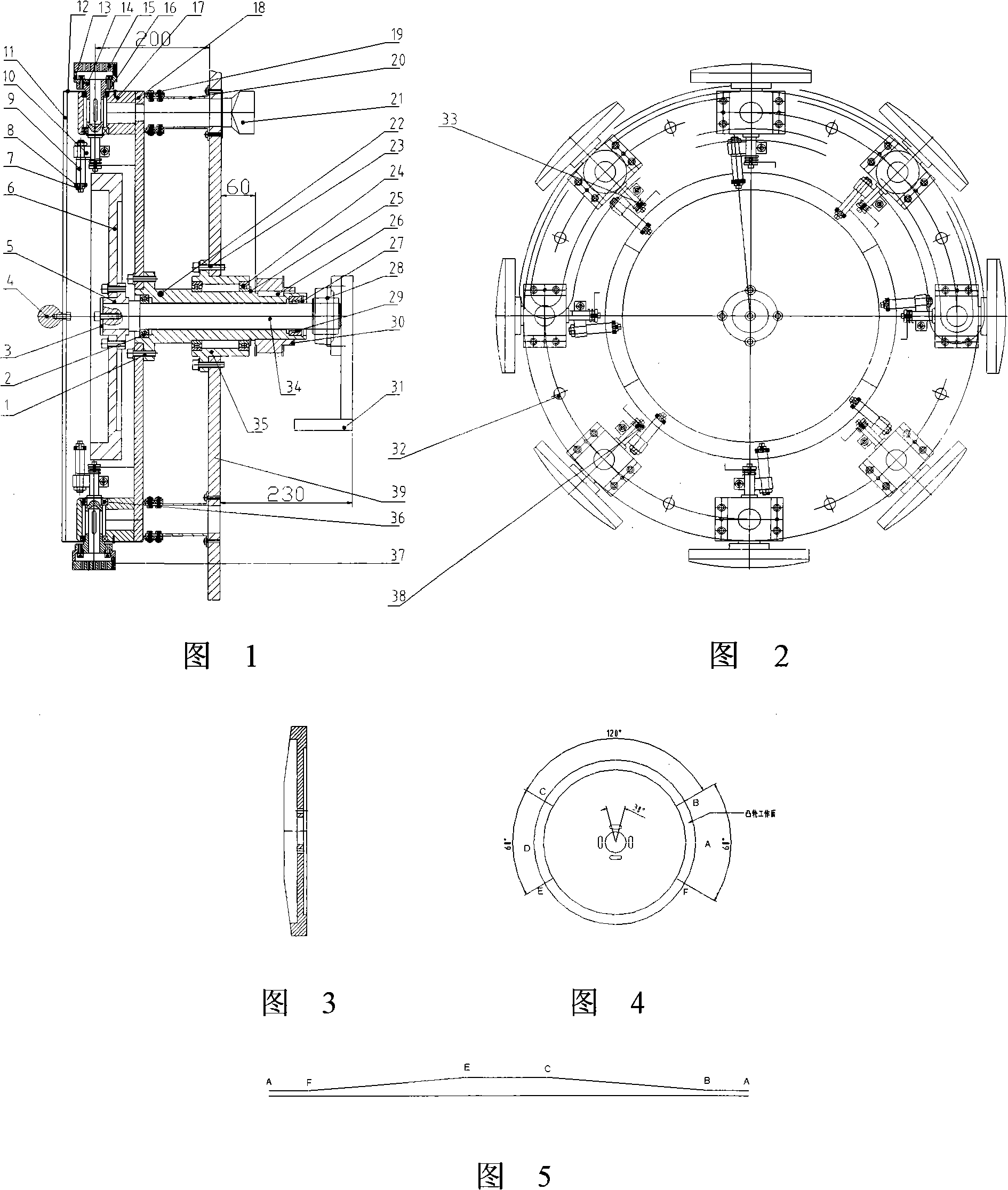

[0013] Embodiment 1: with reference to accompanying drawing 1~3. The sanitary napkin covers the diverter, the outer shaft 23 is processed by the prior art and is sleeved on the inner shaft 35 through the bearing 2, the bearing 30 and the retaining ring 28 for the hole, the inner shaft 35 is located on the bearing seat 29 of the support plate 32 and the inner Axle 35 does not rotate, and fixed disc 19 is enclosed within on the outer shaft 23 and adopts screw to be connected with outer shaft, and the cam working surface of end face cam 6 is the circumferential working surface that is formed by upslope, horizontal plane, downslope, and horizontal plane, and upslope is 120 degrees, 120 degrees for the downslope, and 60 degrees for the horizontal plane. The end face cam 6 is set on the inner shaft 35 through the flange plate 5 and is located on the side of the fixed plate 19. The baffle plate 3 is fixed on the end face of the inner shaft 35. Two or A plurality of negative pressure ...

Embodiment 2

[0014] Embodiment 2: On the basis of Embodiment 1, the azimuth transformation method of the sanitary napkin covering the steering gear, the power mechanism drives the outer shaft to rotate, the outer shaft drives the fixed disk to rotate, and the fixed disk drives the end of the pendulum shaft in the negative pressure suction device During the rotation of the bearing along the working surface of the end cam, the pendulum shaft drives the negative pressure suction device to rotate gradually through the connecting rod. (1) When the bearing moves to the highest end of the upward slope of the cam, the negative pressure suction device rotates 90 degrees , and then enter the horizontal plane of the cam working surface, and the negative pressure suction device does not rotate. (2) When the bearing shaft rotates from the cam level to the lowest surface of the cam downslope, when the bearing rotates to the cam’s upslope, the pendulum shaft passes through The connecting rod drives the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com