Multifunctional gypsum block die

A gypsum block, multi-functional technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of high cost of molding devices, increased production costs, high power of molding devices, etc., to reduce production costs, save production costs, and consume less energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

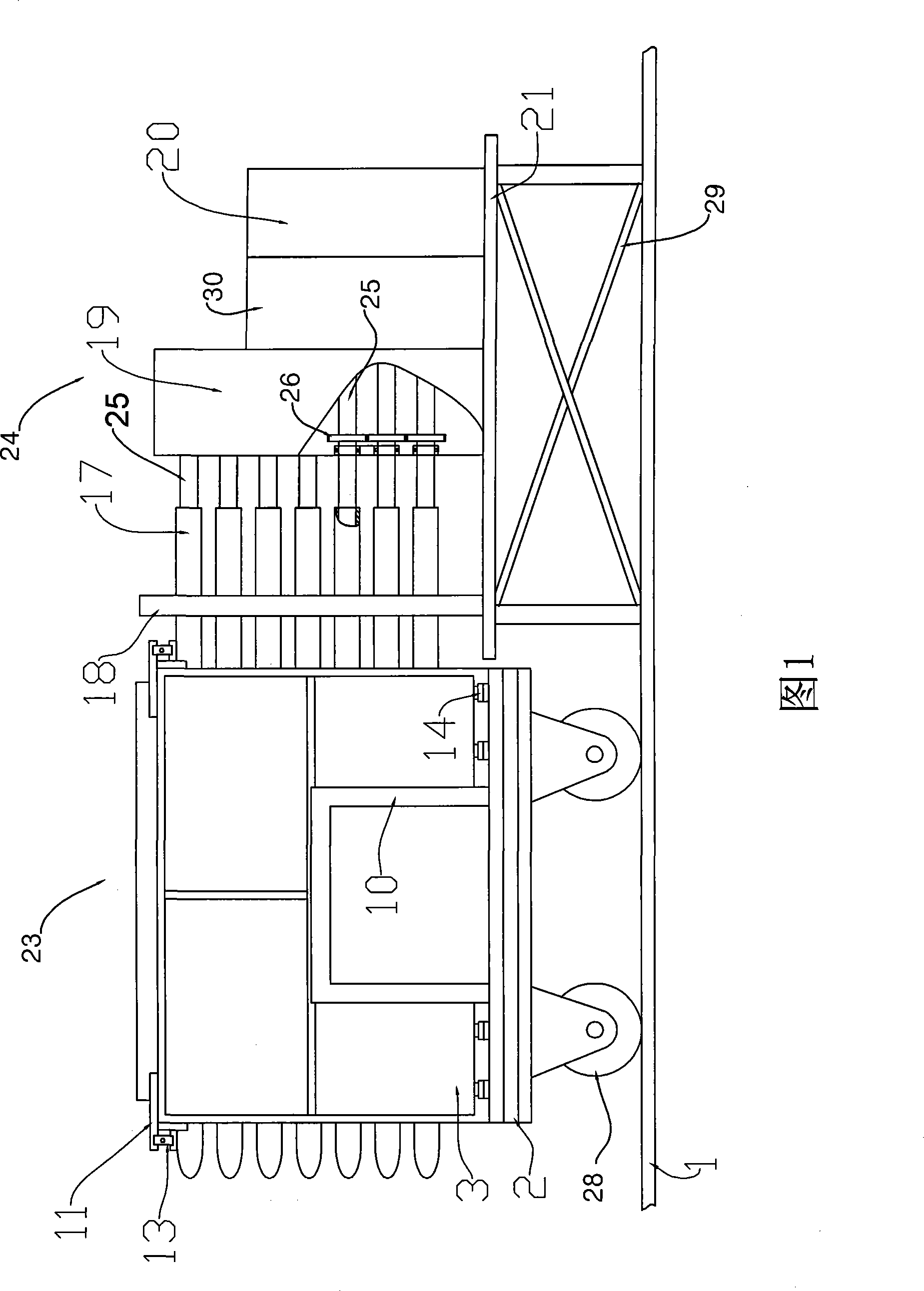

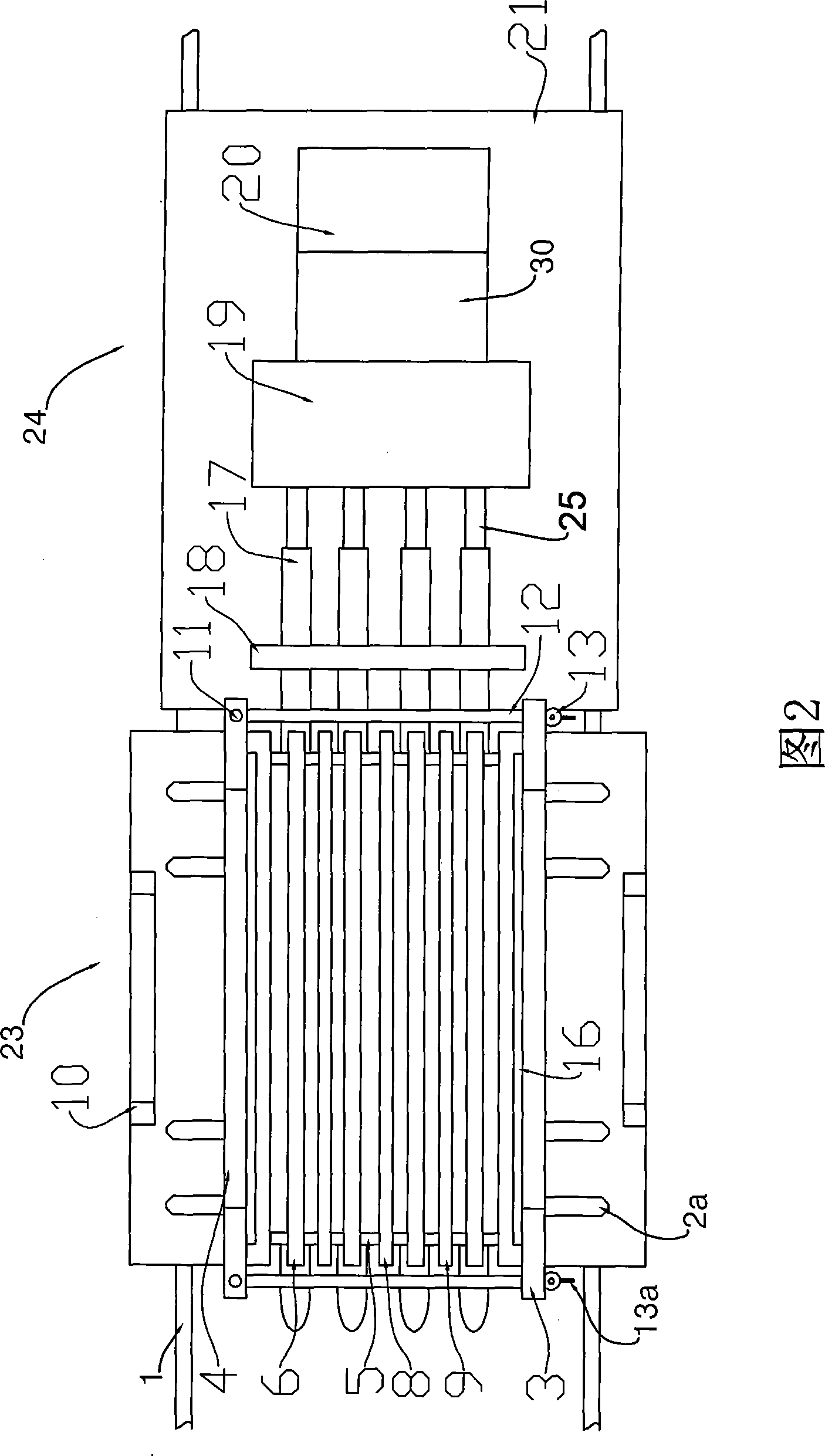

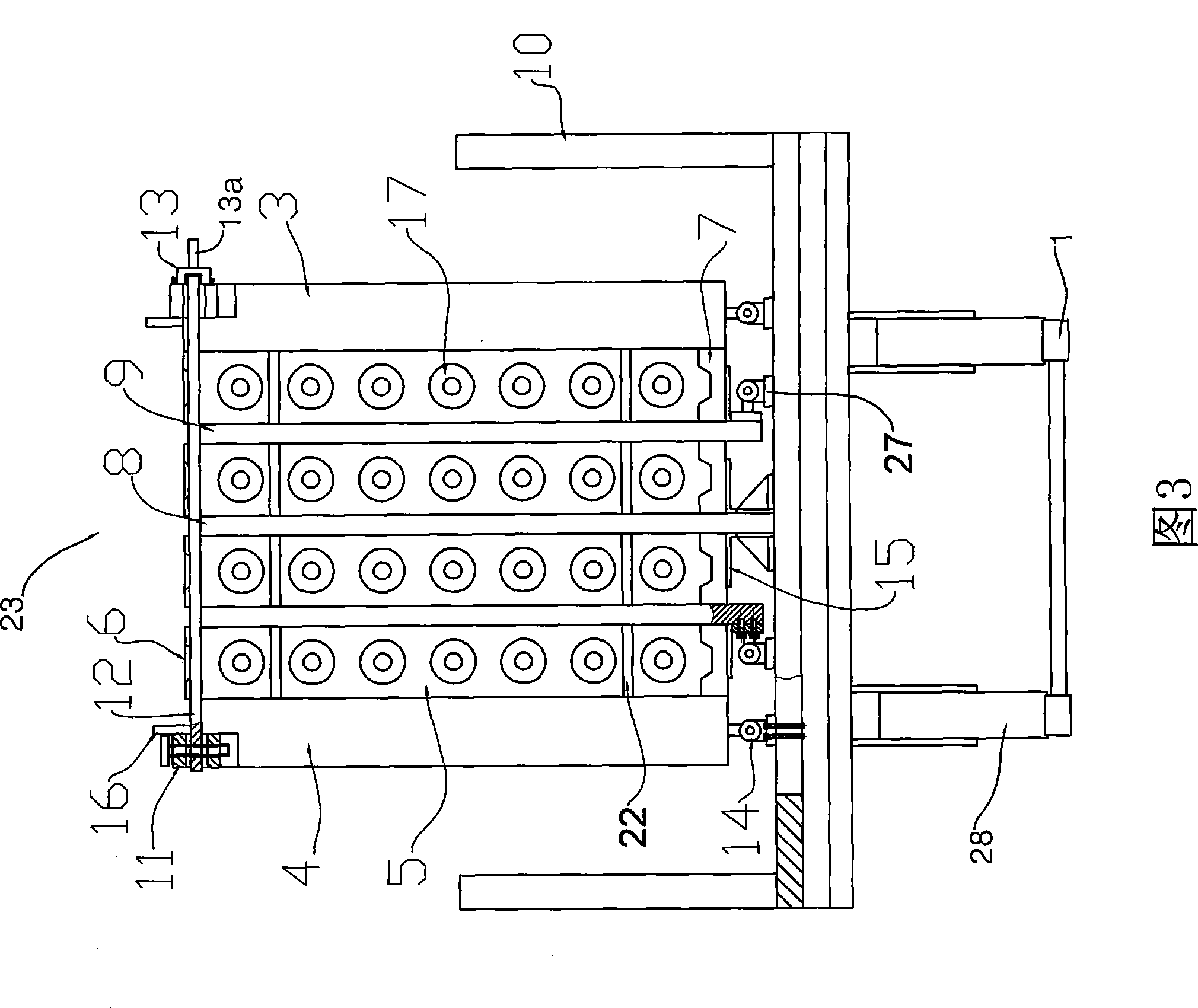

[0027] As shown in Fig. 1, Fig. 2 and Fig. 3, be multifunctional gypsum block mould, this mold mainly is made up of mold box car 23 and pumping hole device 24, and mold box car 23 can slide back and forth on track 1.

[0028] Mold box trolley 23 is made up of base 2, front side template 3 and rear side template 4, fixed partition 8, movable partition 9 and end template 5 etc., and the lower surface of base 2 is equipped with wheel 28, and wheel 28 can drive mold box The car 23 moves back and forth on the fixed track 1; the front side template 3 and the rear side template 4 parallel to each other are installed above the base 2, and the first hinge 14 is assembled on the lower end of the front side template 3 and the rear side template 4, as Fig. 4, four bar-shaped holes 2a are arranged symmetrically along the longitudinal centerline of the base 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com