Device and method for operating sheet stretching straightener

A technology for drawing and leveling machine and sheet, which is applied in the field of devices and methods for running sheet drawing and leveling machine, can solve the problems of damage to bending boxes, enlargement of gaps or gaps, etc., and achieves the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

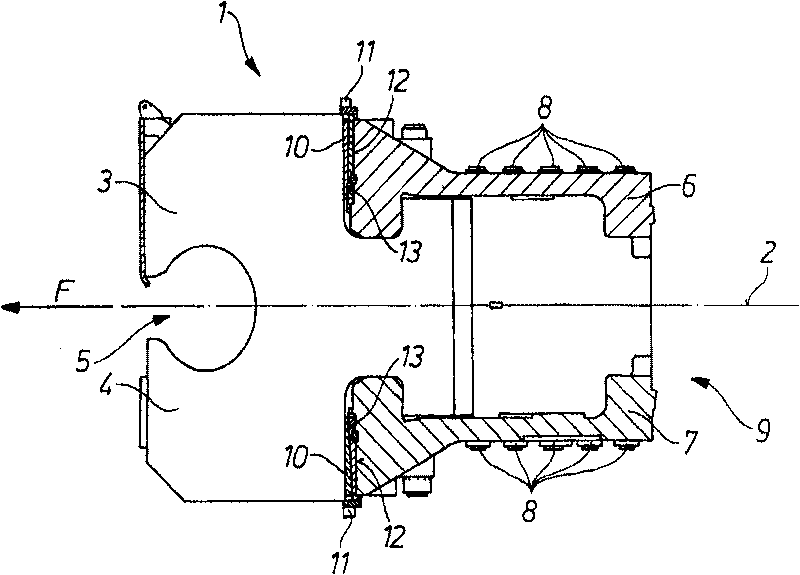

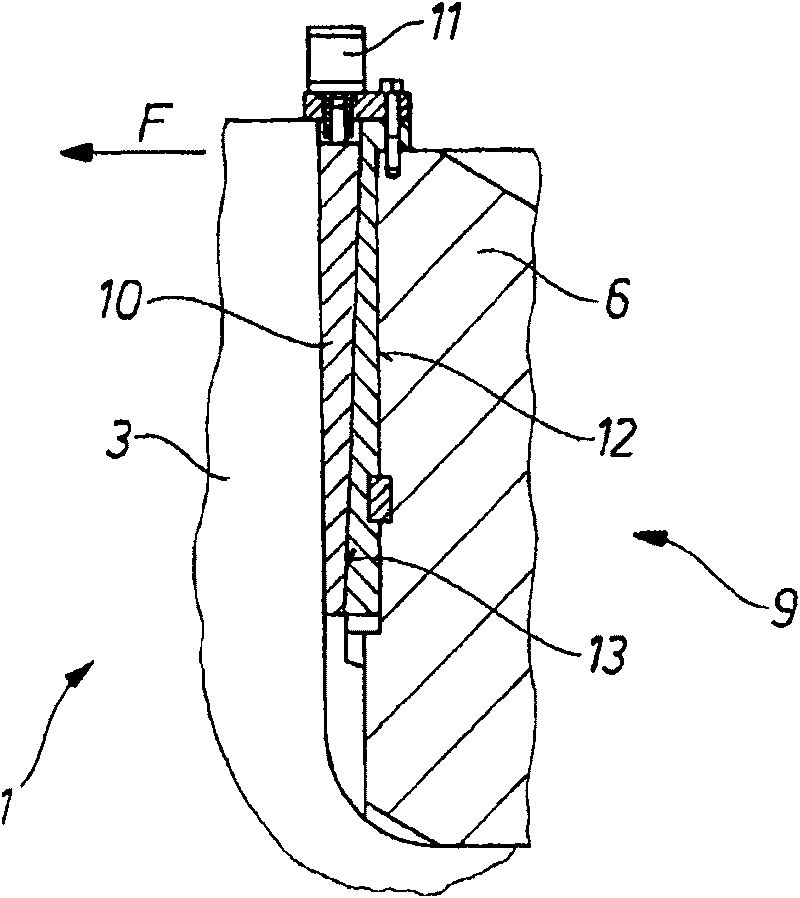

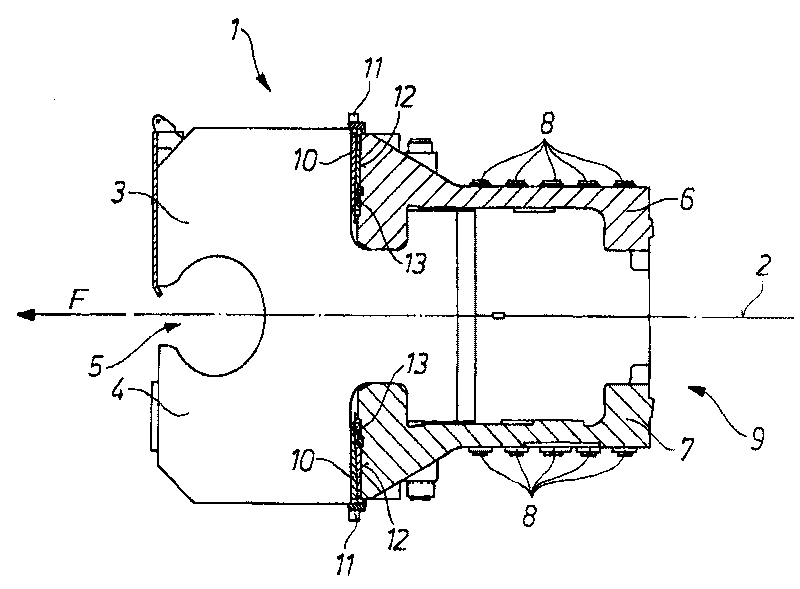

[0017] figure 1 The clamping head 1 of the sheet metal stretching straightening machine shown is made up of a plurality of laminations 3, 4 arranged side by side perpendicular to the stretching plane 2, which form a form-fitting connection with the not shown in detail here, generally made of particles. The C-shaped jaw 5 formed of structural steel is surrounded by its entire width. In the C-shaped opening facing the working area of the jaw 5, there are clamping devices required for clamping the stretched object. At the top and bottom of the lamellae 3 , 4 there are shells 6 , 7 (upper shell and lower shell) forming a bending box 9 running transversely to the stretching plane 2 . The two shell parts 6 , 7 are braced against each other by means of tensioning screws 8 , so that the individual lamellae 3 , 4 and the jaws 5 delimited by them are connected to each other in a non-positive manner.

[0018] Wedge-shaped tensioning elements 10 are respectively provided at the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com