Twist system fiber filter

A fiber filter and fiber bundle technology, which is applied in the field of liquid-solid separation devices, can solve the problems of uneven filtration pores, unstable effluent quality, slow filtration speed, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

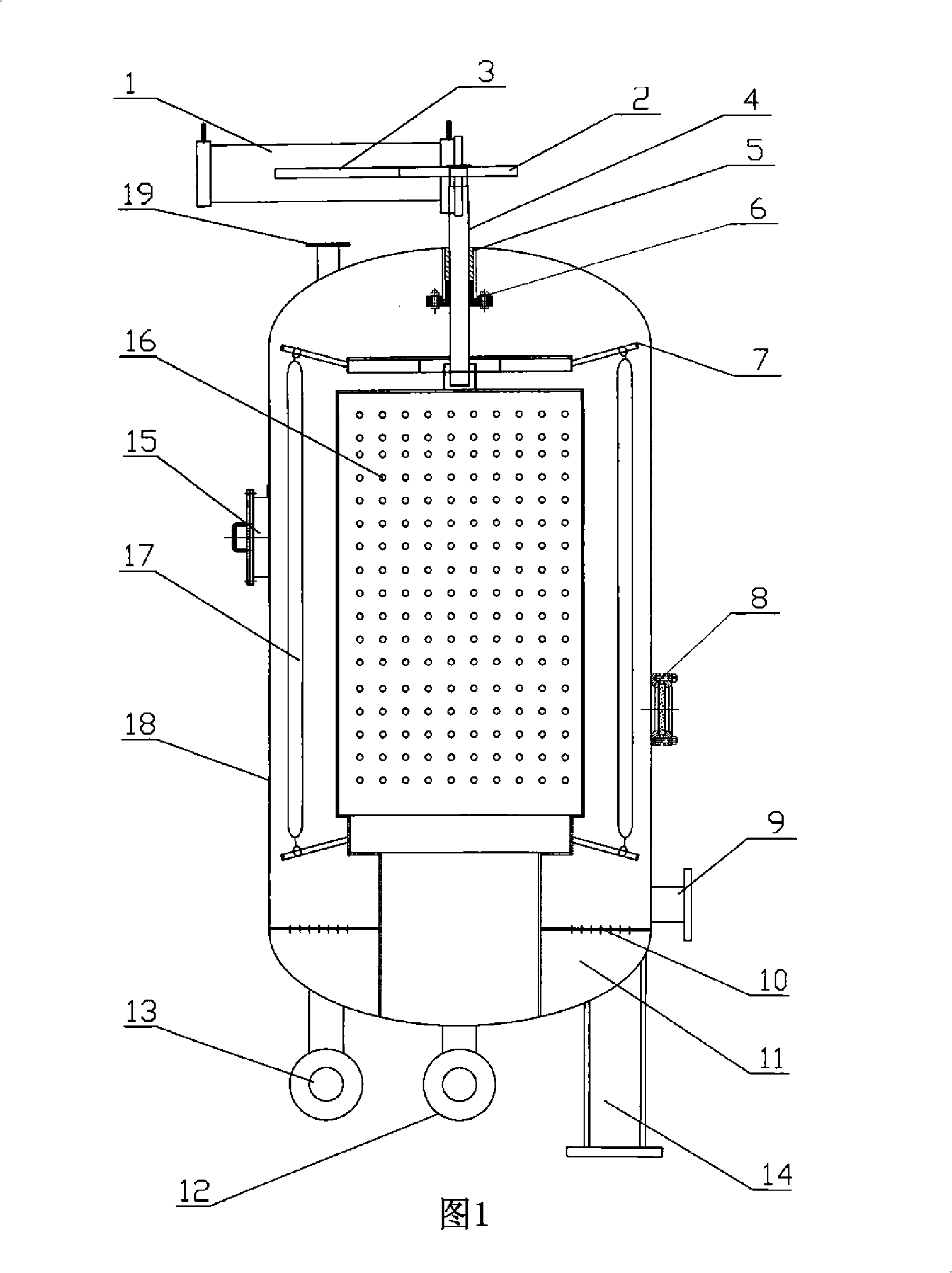

[0026] Embodiment 1 see Figure 1- image 3 , this single element twisted fiber filter includes a housing 18, fiber bundles inside the housing and a fiber bundle support body, the housing is provided with an inlet pipe 9 and an outlet pipe 12, and it is characterized in that: the housing interior is equipped with at least A porous filter cartridge 16, the bottom of each porous filter cartridge is connected to the transmission shaft 4, the transmission shaft 4 passes through the outside of the housing, and is connected to the torsion drive device 1 through the transmission mechanism; the outlet end of the porous filter cartridge passes through the air distribution plate 10 communicates with the water outlet pipe 12, air holes are distributed on the air distribution plate 10, and the air distribution plate is divided into an air distribution chamber 11 at the head of the shell. There is a backwash drain pipe 19; the above-mentioned transmission shaft and the outlet end of the por...

Embodiment 2

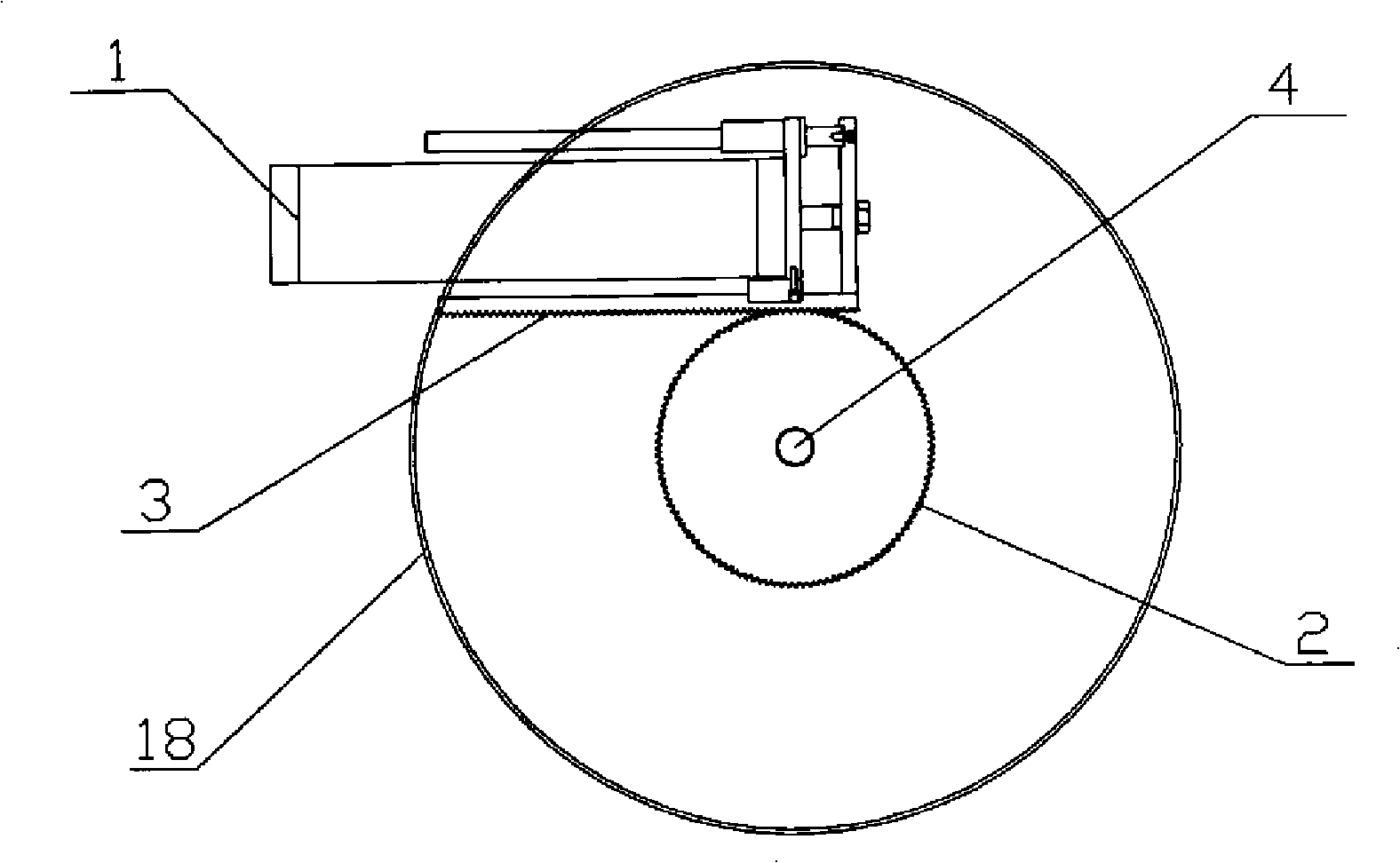

[0033] Embodiment 2 is a twisted fiber filter with multiple filter elements, see Fig. 4 Figure 5 , the difference from Embodiment 1 is that four or more porous filter cartridges 16 are arranged inside the housing, and one or more driving devices 1 are arranged outside the housing, and the driving devices drive four or more filter cartridges by rotating the rack respectively. Gear 2 rotates, and gear 2 is connected with an end of transmission shaft 4 respectively again, and the other end of transmission shaft 4 is connected with top hanging screw rod 7 again.

[0034] The straight pipes at the bottom of four or more porous filter cartridges 16 are all connected to the outlet pipe 12 outside the housing, and the outer sides 21 of the straight pipes are respectively provided with air distribution discs 10, and the backwash air inlet pipe 13 at the bottom of the housing is divided into four or more, communicating with four or more air distribution chambers 11 respectively.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com