Novel fibre filter

A fiber filter, a new type of technology, applied in the direction of loose filter material filter, filter separation, gravity filter, etc., can solve the problems of large floor area, incomplete backwashing, large filter resistance, etc. Small size, good effluent quality, high effluent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

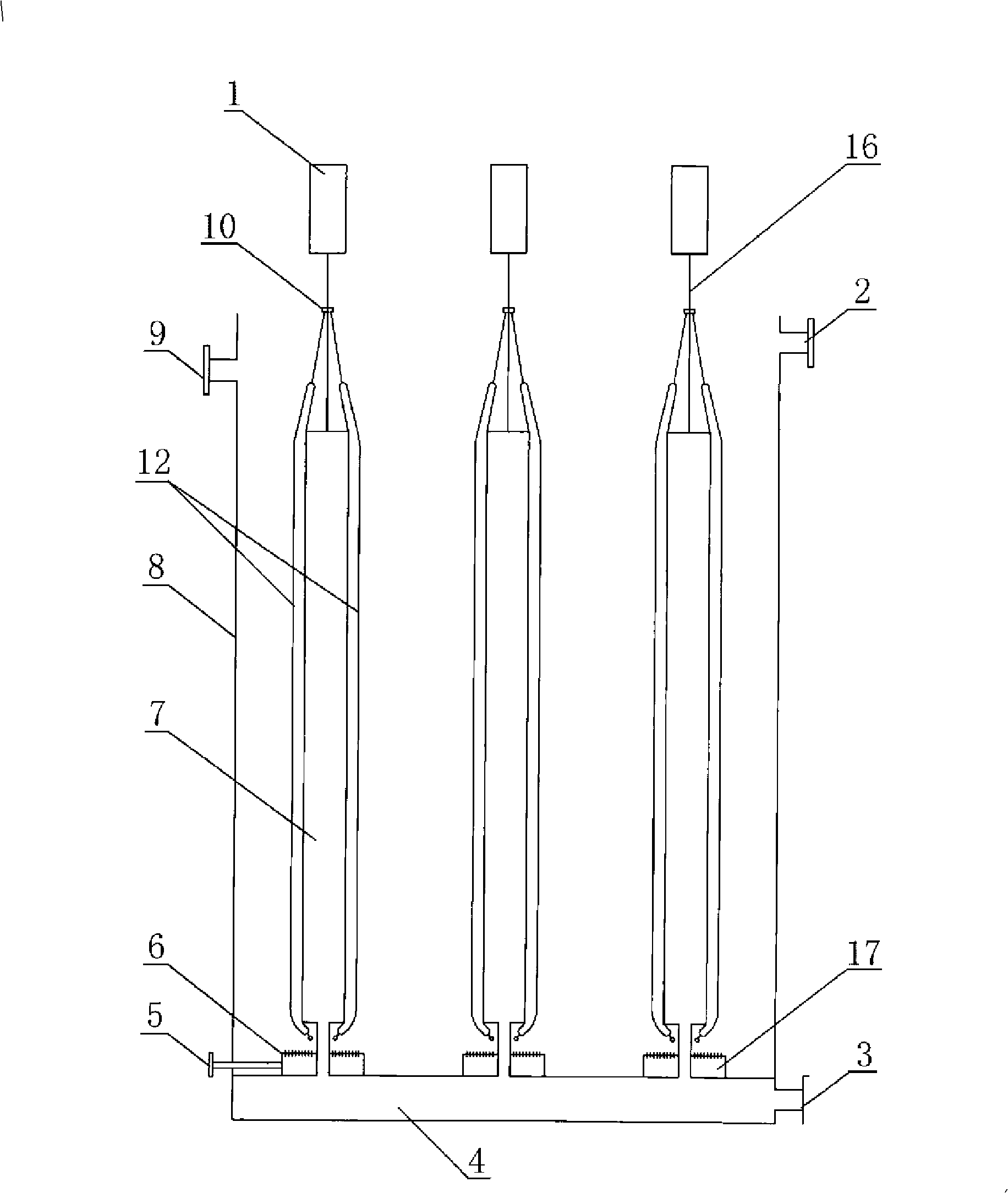

[0025] Examples see figure 1 As shown, in this novel fiber filter tank, fiber bundles 12 and hollow support body 7 are housed in the tank body 8, and the side wall of the tank body 8 has a water inlet 9, a water outlet 3 and a backwash drain 2. The above-mentioned pool body 8 is a cylindrical pool body, a square pool body or a rectangular pool body. The bottom space of the pool body 8 is provided with an outlet water collection box 4, and the side of the water outlet water collection box 4 communicates with the water outlet 3; the upper surface of the water outlet collection box 4 is connected with at least one upright filter unit. An air distribution chamber 17 is arranged at the root of each filter unit, and there is a backwash aeration disc 6 on the air distribution chamber. , Stretch out of the pool body 8.

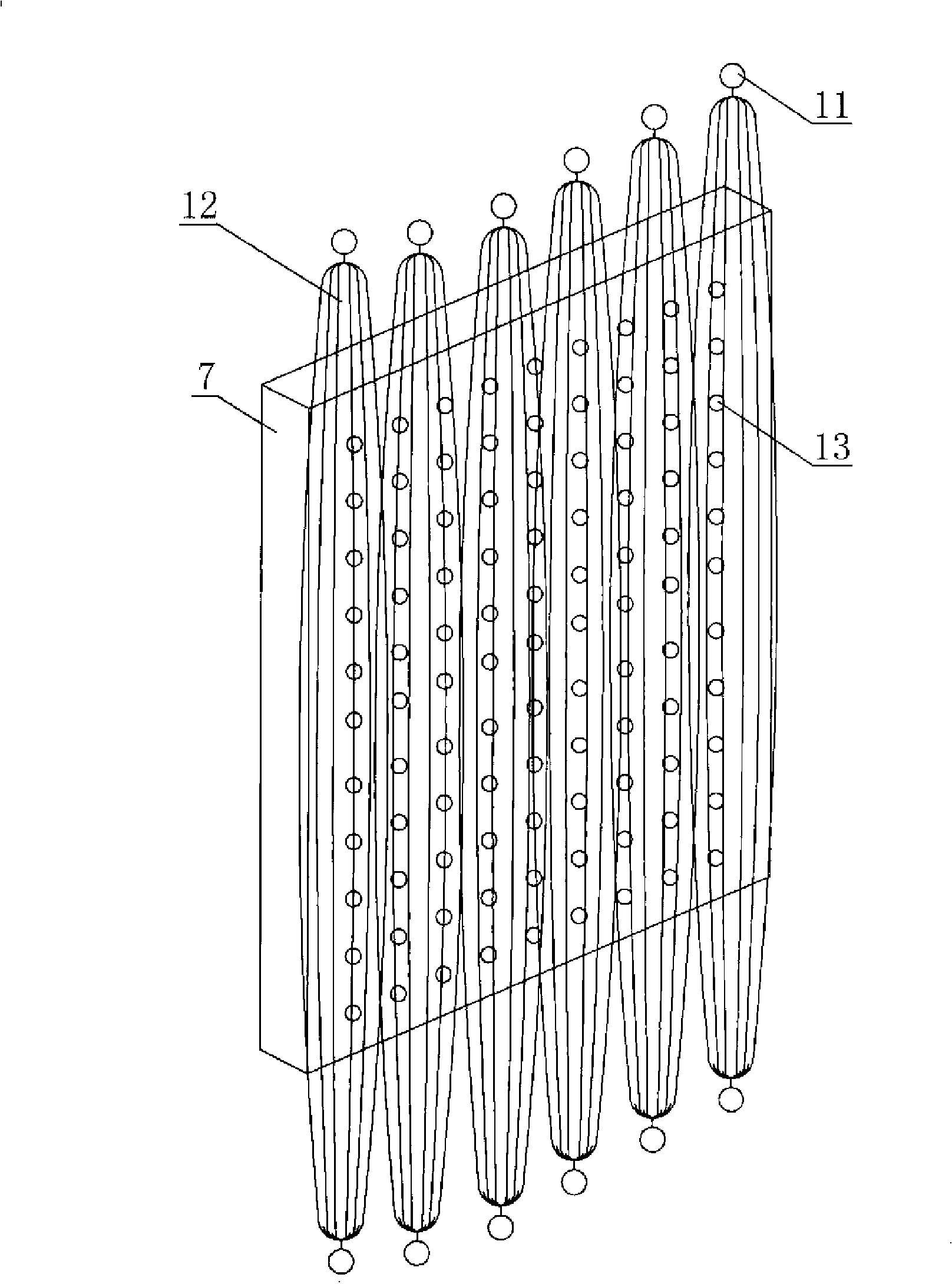

[0026] see figure 2 , image 3 , the center of each filter unit is a hollow support body 7, filter holes 13 are distributed on the side wall of the hollow suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com