Safety syringe

A technology of safety syringe and movable installation, which is applied in the field of medical devices, can solve the problems of unstable performance and large residual liquid, and achieve the effect of reasonable structure, good safety performance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

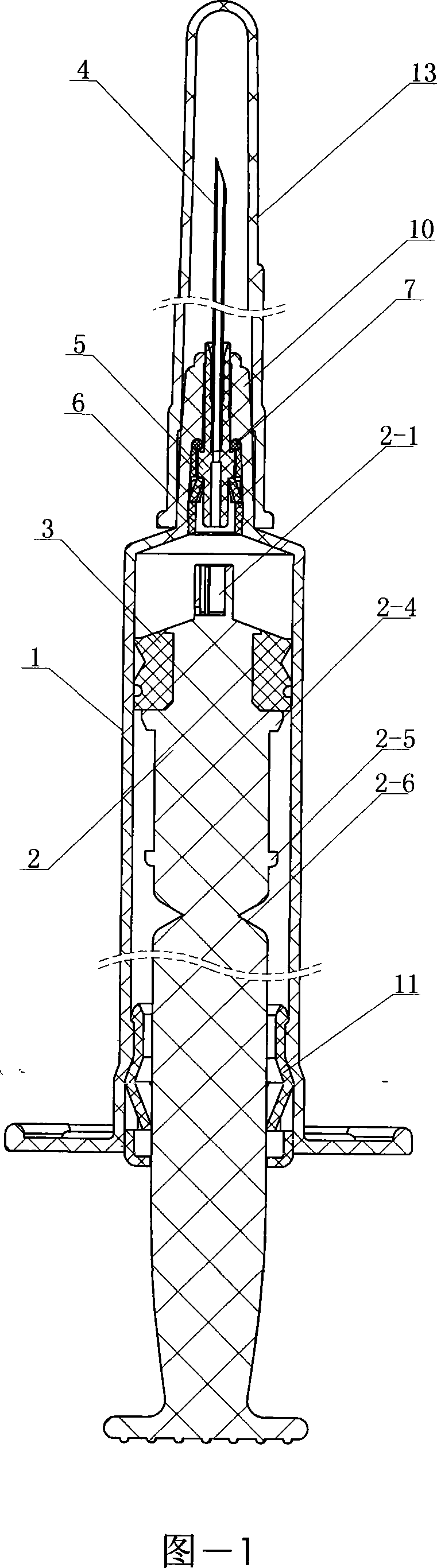

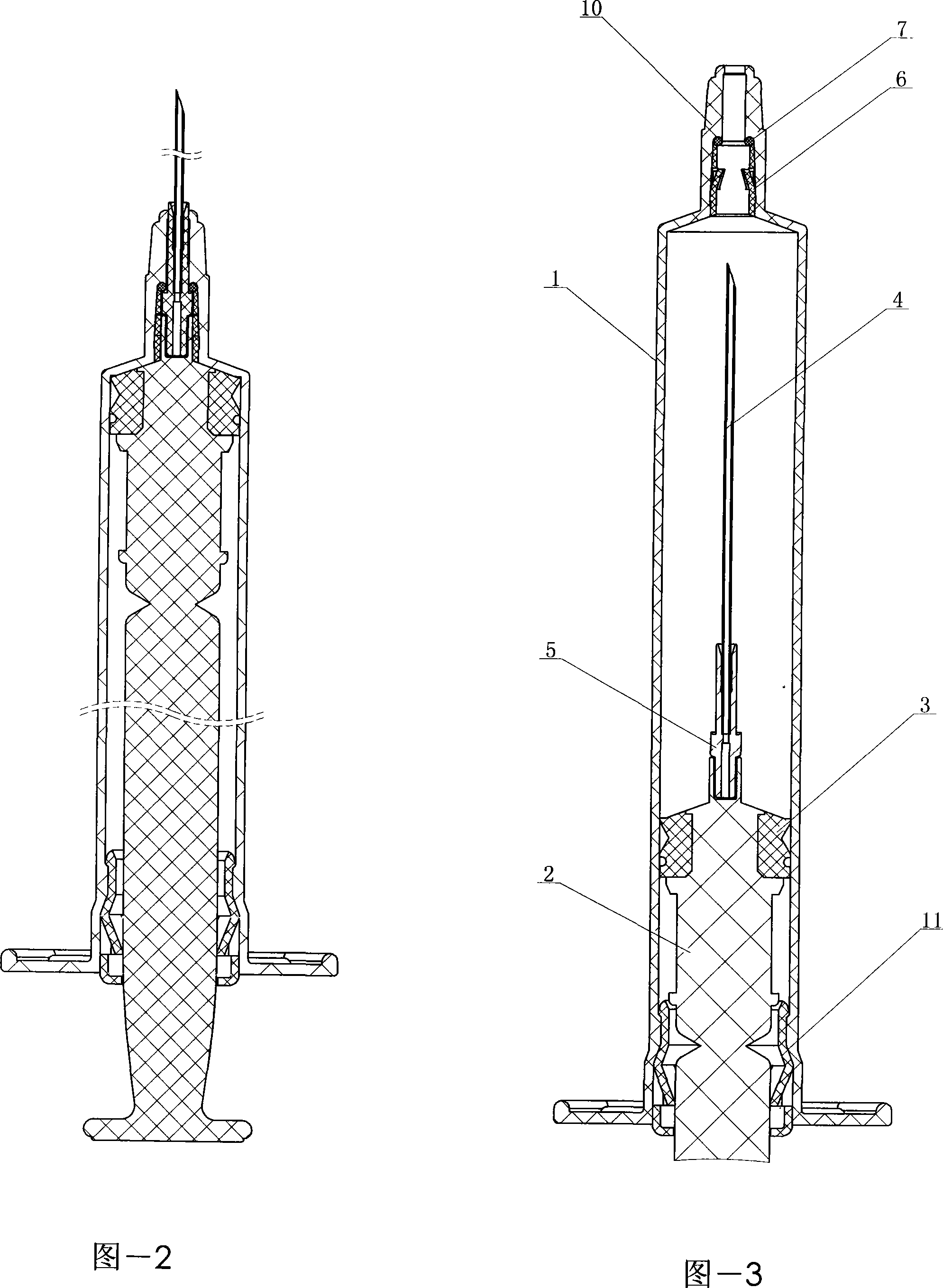

[0020] As can be seen from FIG. 1 , a safety syringe includes a casing 1 , a core rod 2 , a piston 3 , a needle assembly, a needle holder 10 , a protective cap 13 and the like. The jacket 1 is a hollow structure, the rear part is equipped with a core rod locking ring 11, and the front part is provided with a needle seat 10, and the needle assembly is installed in the needle seat 10. The piston 3 is a good elastic body, which is installed and fixed in front of the core rod 2. The part can move in the inner cavity of the jacket 1, suck or inject the medicinal liquid.

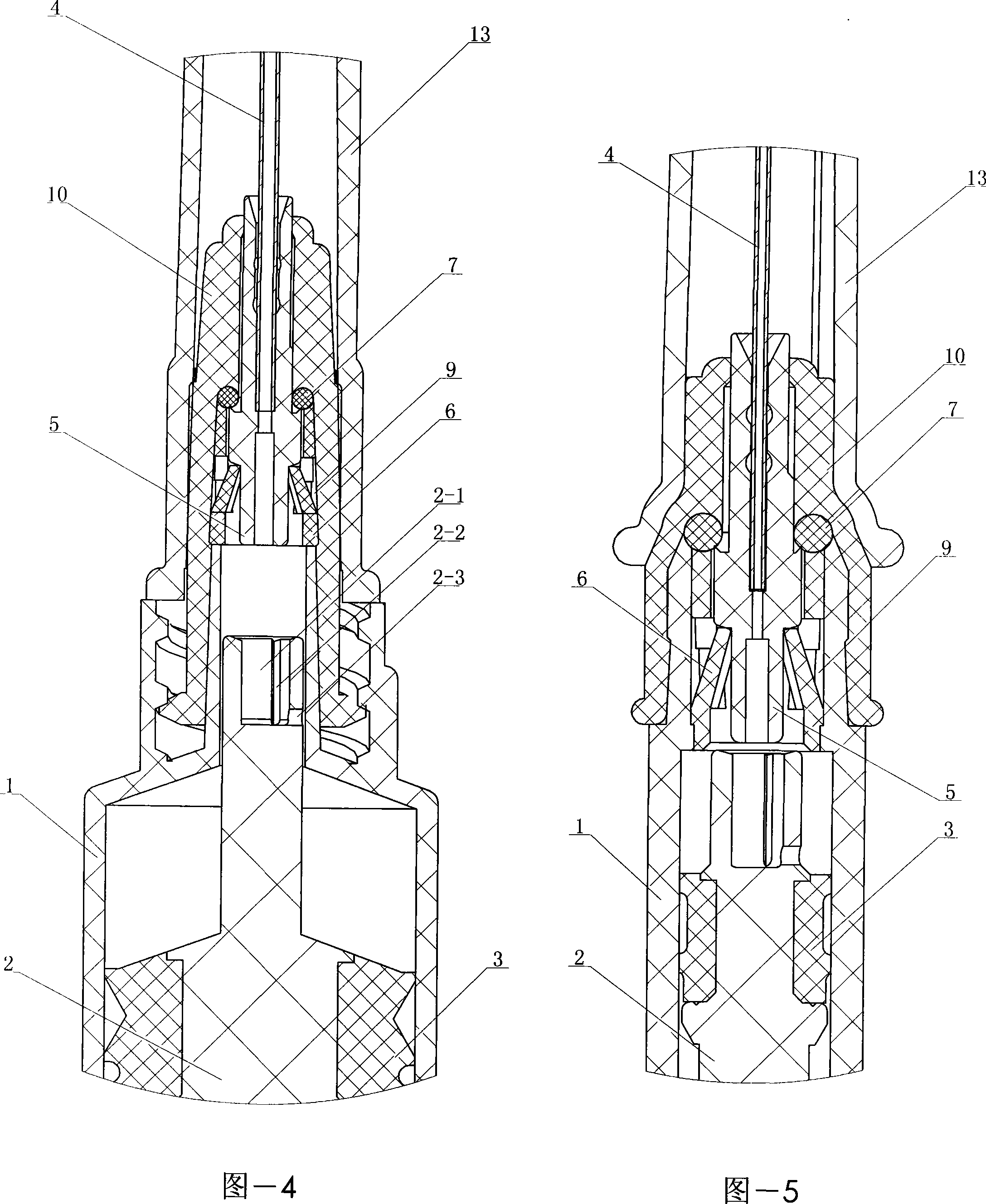

[0021] As can be seen from Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5, the needle assembly of the present invention includes a needle tube 4, a needle tube seat 5, a needle tube seat snap ring 6, and a sealing ring 7, and the needle tube 4 is bonded and fixed on the needle tube In the needle tube through hole of the seat 5, the needle tube seat 5 is movably installed in the needle seat 10 at the front of the overc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com