Mechanical weighing mechanism of high pedestal jib crane dynamic grab bucket electronic weighing scale

A portal crane and weighing mechanism technology, which is applied in the field of mechanical weighing mechanism, can solve the problems of measurement inaccuracy, repeatability error, and poor measurement consistency, and achieve the effect of accurate and rapid measurement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but not as a further limitation to the present invention.

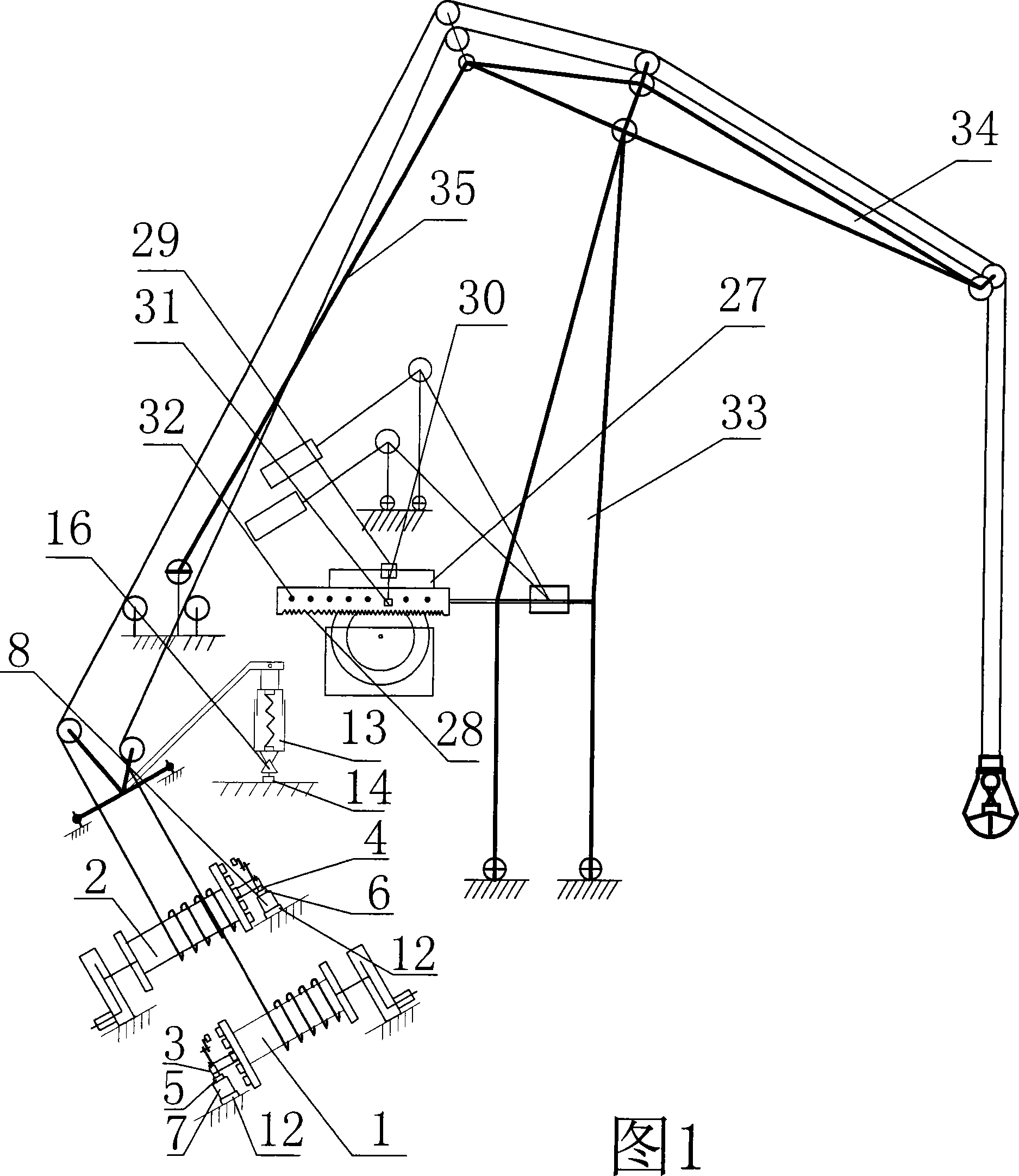

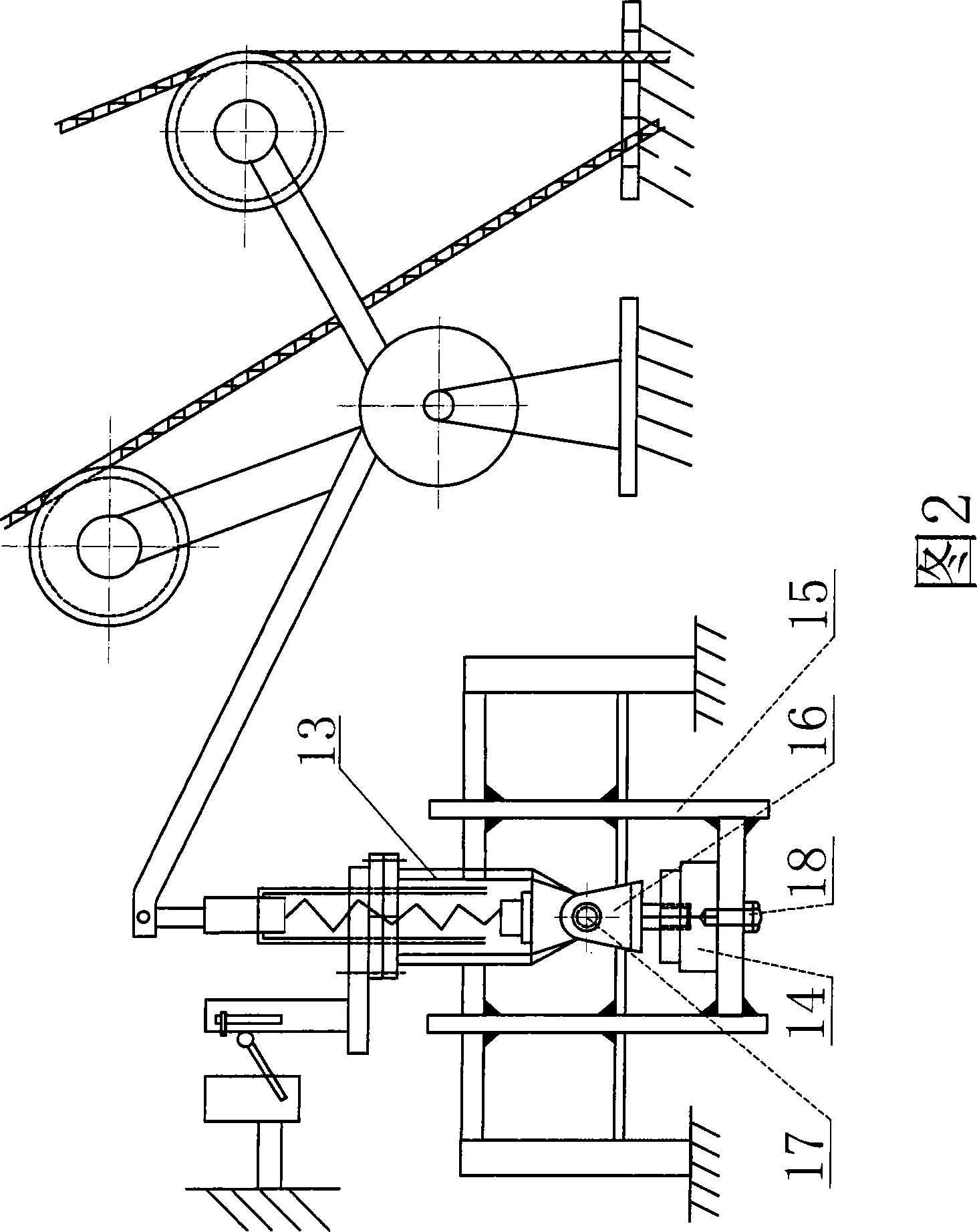

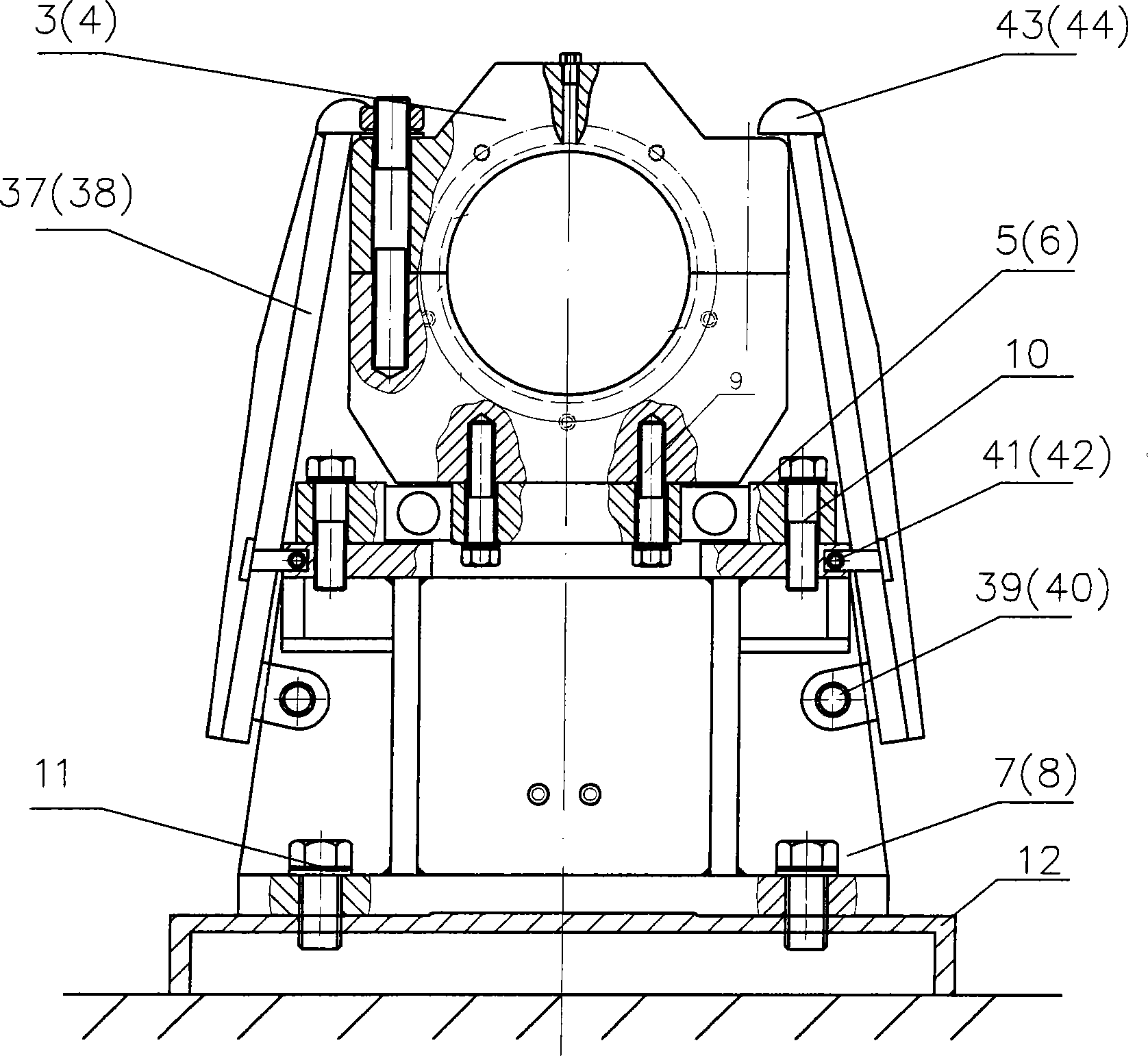

[0033] The overall technical structure of this embodiment is shown in the figure, in which the shaft heads of the drive shafts of the main and auxiliary hook drums 1 and 2 of the door machine are respectively connected with the bearing housings 3 and 4 and then press-fitted on the upper surfaces of the flat sensors 5 and 6 , the plate type sensors 5,6 are fixed on the chassis 12 of the door machine room through the support bases 7,8, and the lower end of the door machine mechanical structural load limiter 13 is equipped with a spoke type load cell 14, which is connected with the plate sensor 5, 6 form the main weighing mechanism of the Trinity.

[0034] The automatic counting mechanism used for amplitude modulation and weighing compensation of the door machine grab electronic scale includes counter frames 29, 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com