Labor saving type manual nail gun

A labor-saving, nail gun technology, applied in the direction of nailing tools, manufacturing tools, etc., can solve the problems of poor work efficiency and labor, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Regarding the techniques, means and effects adopted in the present invention, a preferred embodiment is given below and described in detail with accompanying drawings.

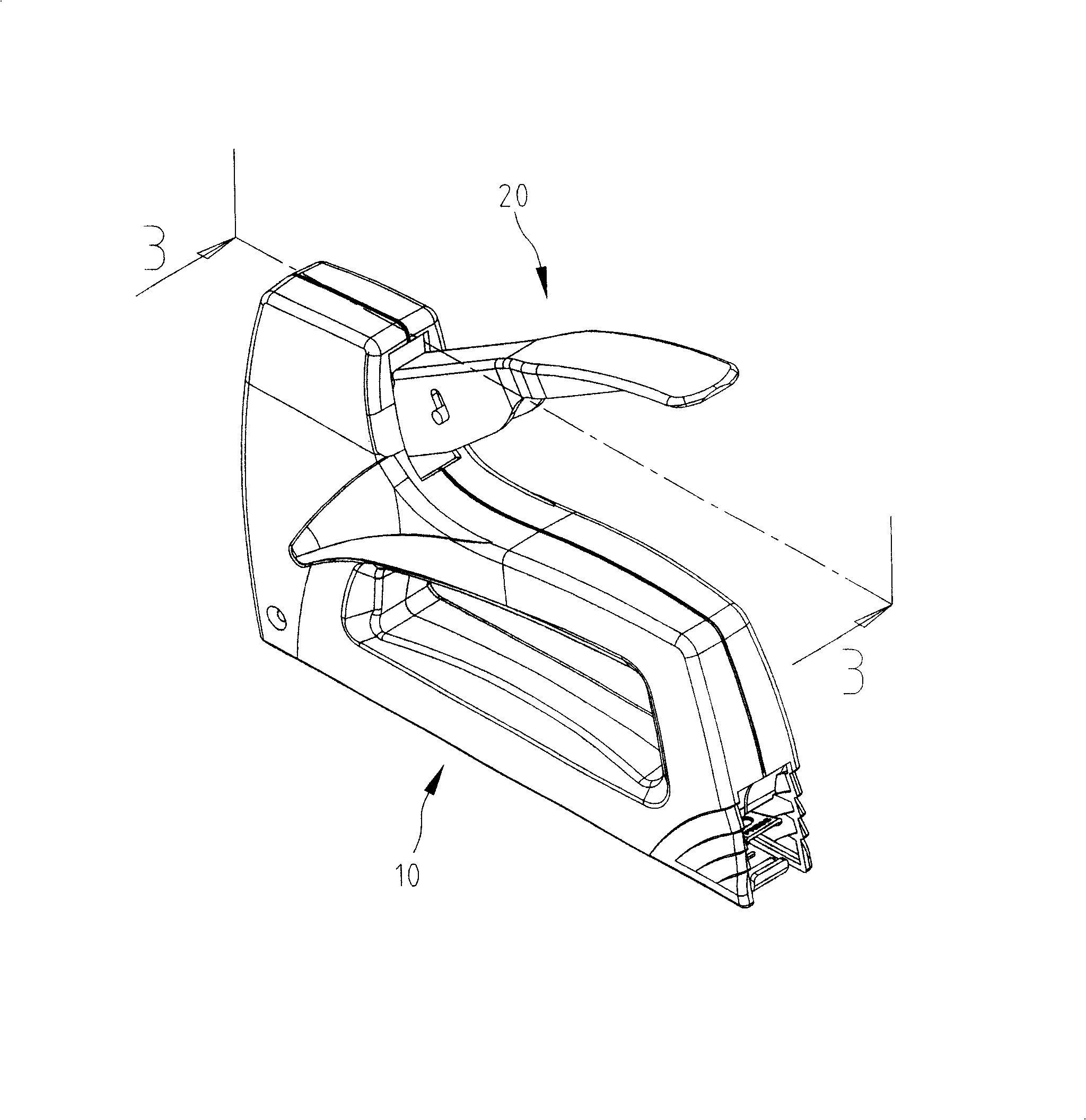

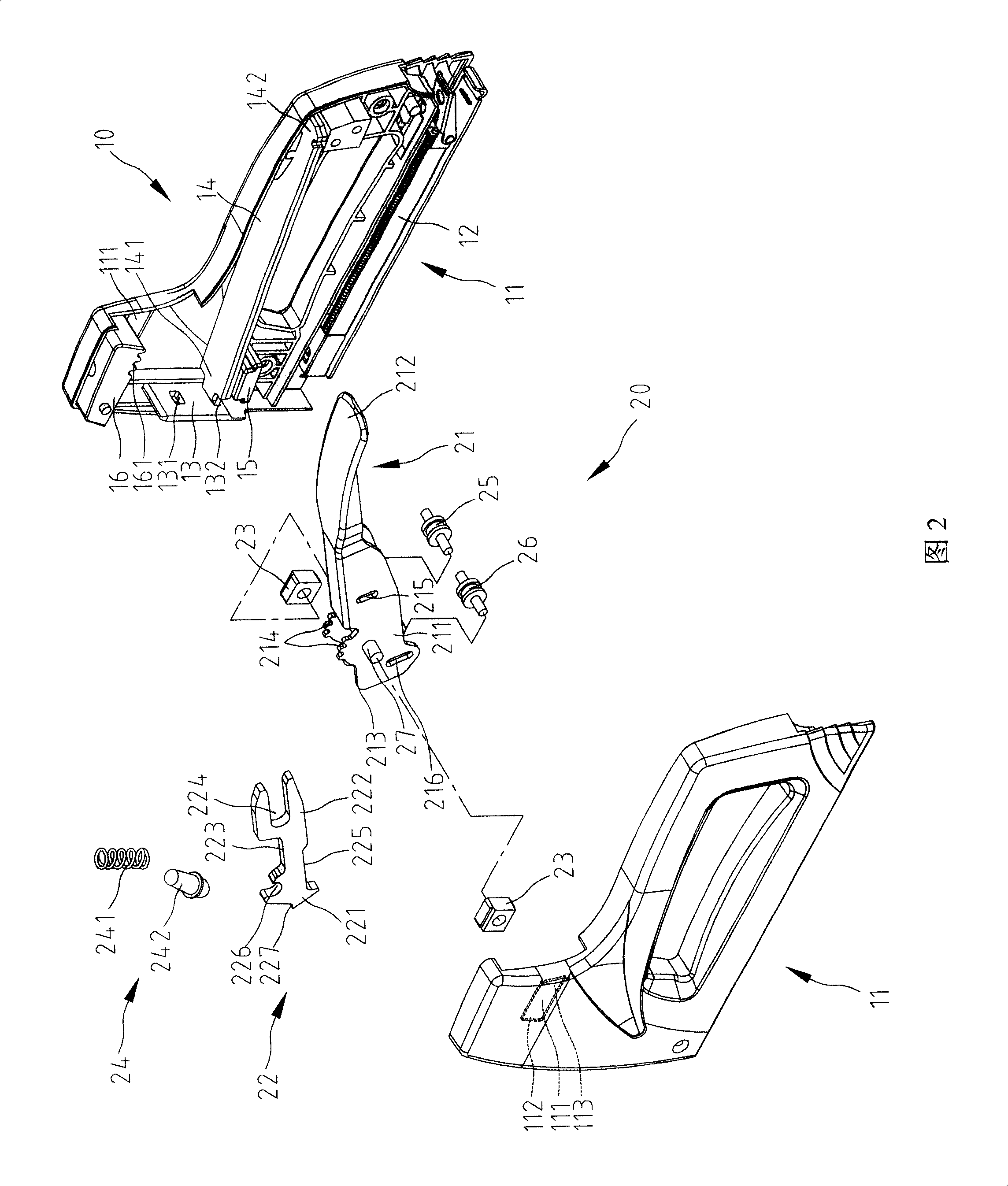

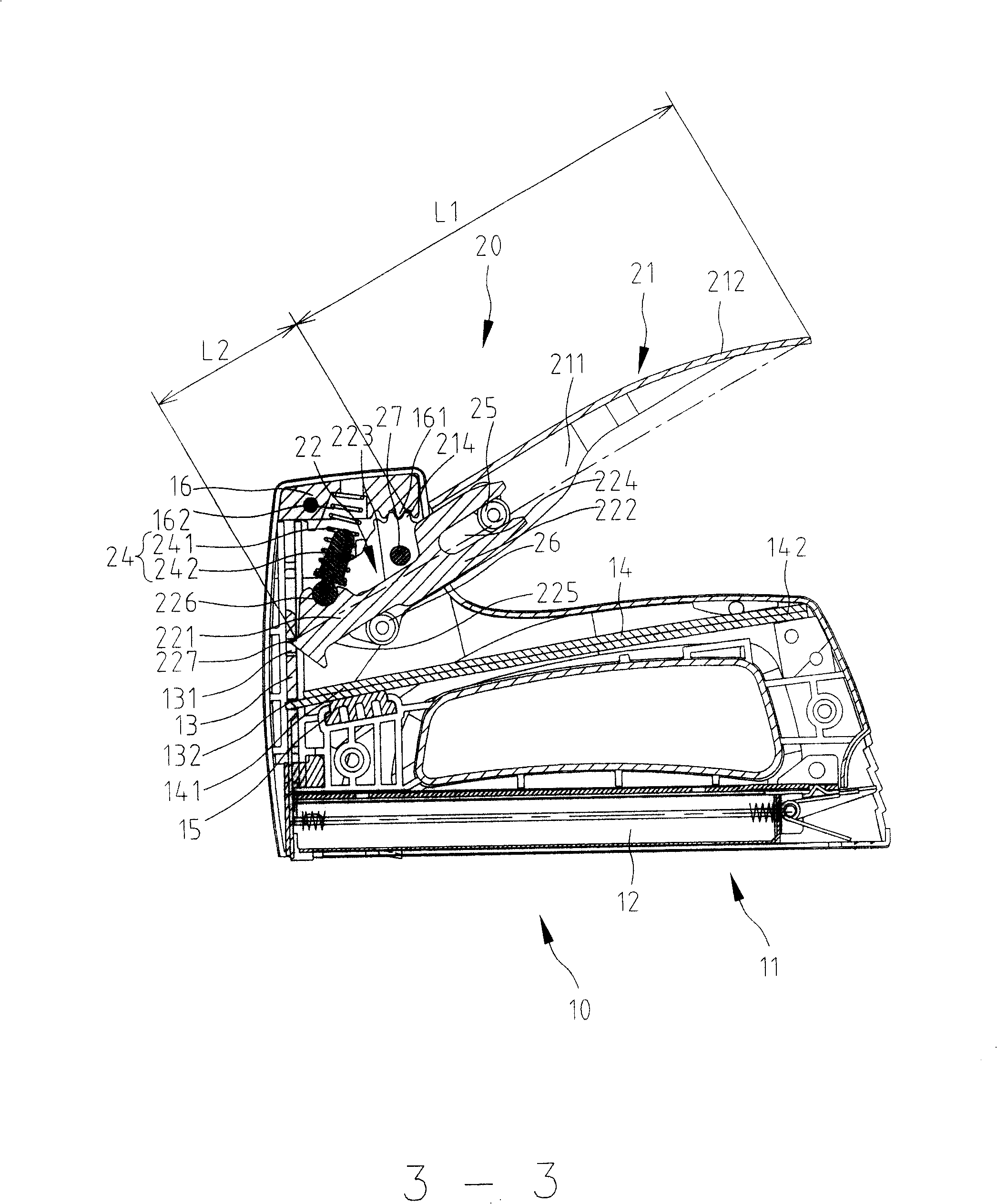

[0039] refer to figure 1 2 , the labor-saving manual nail gun of the present invention includes a nail gun 10 and a labor-saving device 20 . The nail gun 10 includes two side housings 11, wherein one end of the two side housings 11 is provided with a nail box 12, and a nailing piece 13 is arranged above the nail box 12, and the nailing piece 13 is provided with a first connecting hole. 131 and a second connection hole 132 . A first end 141 of the elastic member 14 forms a protrusion to pass through the second connecting hole 132 of the nailing piece 13 , and the side housing 11 is provided with a buffer block at the wall of the first end 141 of the elastic member 14 15 , the second end 142 is limitedly locked on the side casing 11 , and the elastic member 14 can be implemented as an elastic piece. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com