Power supply system for slide door

A technology of power supply device and sliding door, which is applied in the installation of cables, the arrangement of cables between relatively moving parts, and doors, etc., which can solve the problems that the bellows cannot be bent greatly, and is easily damaged and damaged, so as to improve the soundness , to avoid the effect of sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The configuration of the power supply device for a sliding door in a preferred embodiment of the present embodiment will be described in detail with reference to the drawings. In addition, components having the same function are denoted by the same reference numerals for simplification of illustration and description.

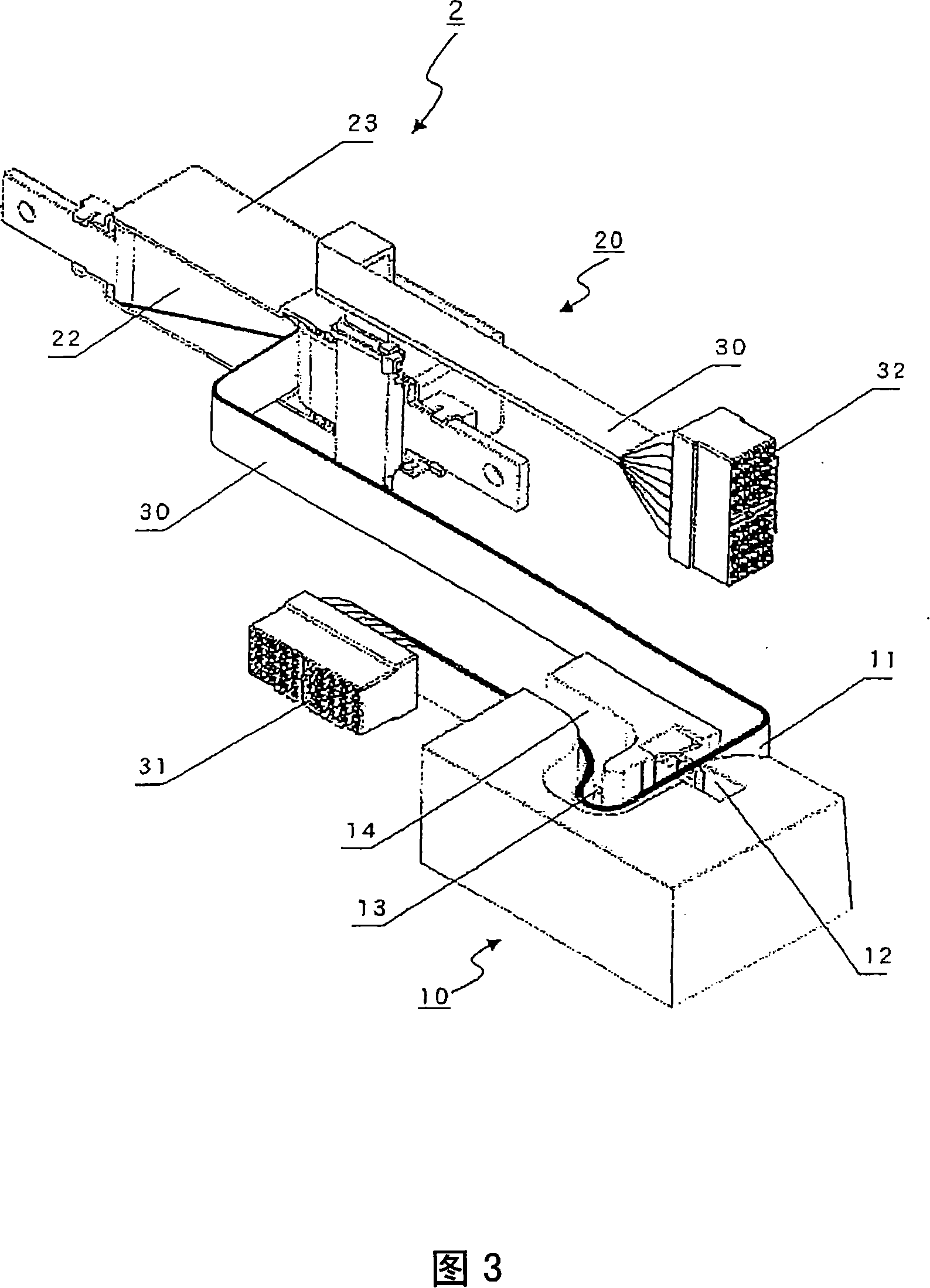

[0072] FIG. 1 is a perspective view showing a schematic configuration of a power supply device for a sliding door according to an embodiment of the present invention. The power supply device 1 for a sliding door according to this embodiment has a vehicle body side fixing unit 10 fixed at a predetermined position of the vehicle body and a door side fixing unit 20 fixed at a predetermined position of the sliding door. Flat cables 30 are distributed between them.

[0073] In the power supply device 1 for a sliding door according to this embodiment, the overlapping portion between the vehicle body side fixing unit 10 and the door side fixing unit 20 uses a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com