Eddy current inspection equipment

A technology of eddy current flaw detection and equipment, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, sorting, and magnetic variables of materials, etc. It can solve problems such as low efficiency, large steel pipe diameters, large lengths, and small application ranges. Easy to operate, high degree of automation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preferred embodiment of the present invention will now be described in detail below with reference to the accompanying drawings.

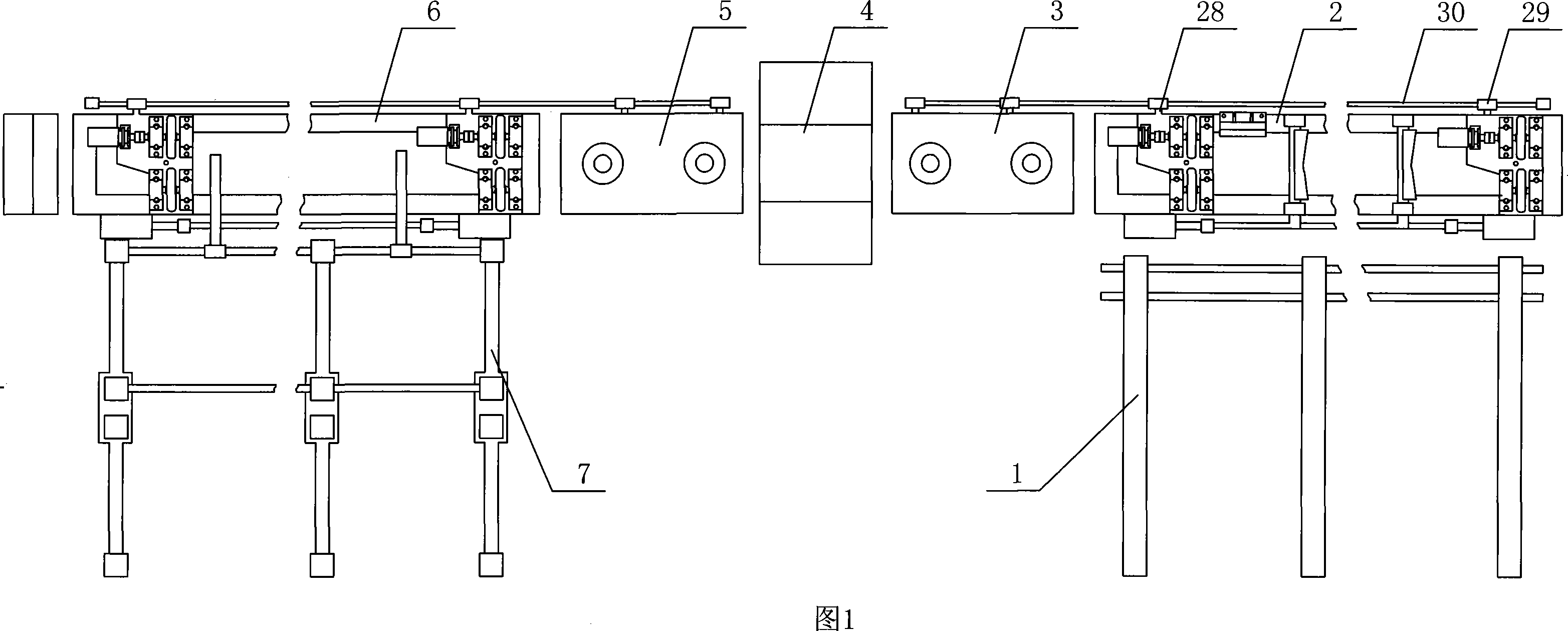

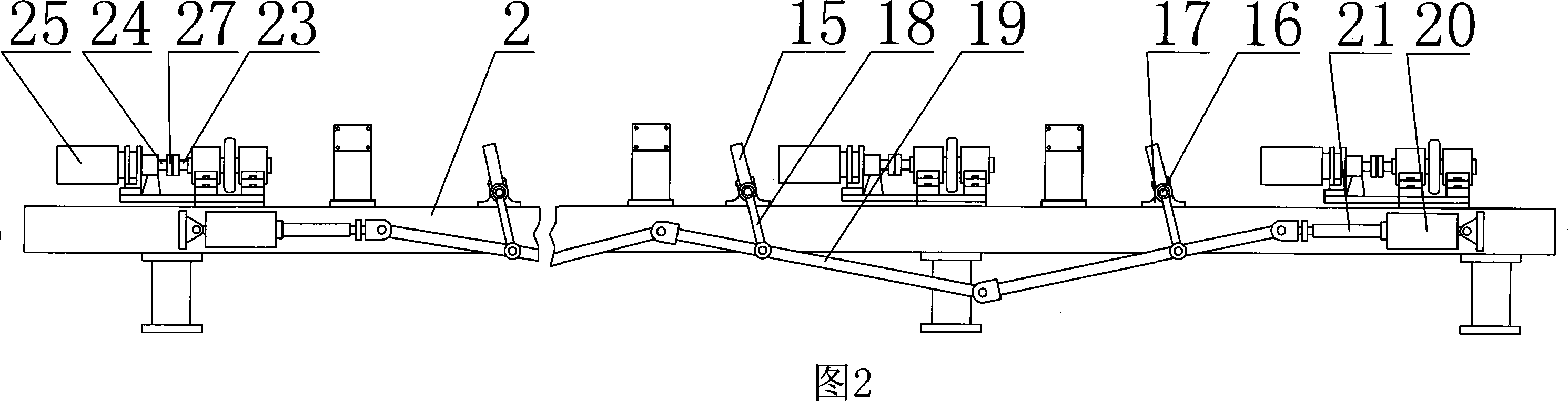

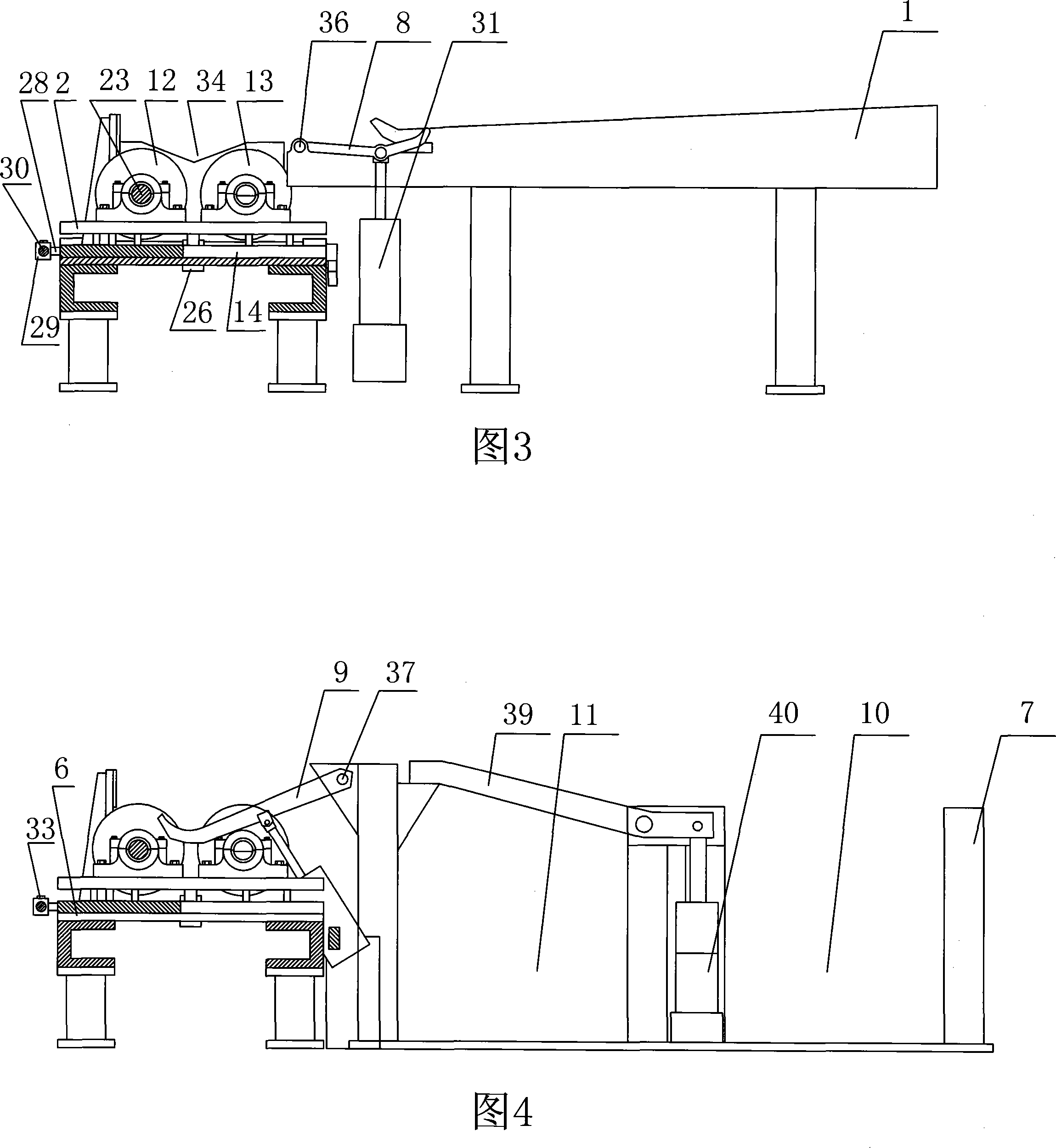

[0038] As shown in Figure 1, the eddy current flaw detection equipment of the present invention is composed of a feeding rack 1, a feeding rail 2, a front pressing wheel mechanism 3, a detection host 4, a feeding rail 6, a feeding frame 7 and a control computer. When conducting non-destructive testing of steel pipes, first place the steel pipes to be tested on the feeding rack 1 neatly. After the non-destructive testing starts, the control computer sends a start command to the cylinder 31 of the feeding rack, and the feeding lever 8 moves the steel pipe to the shelf 15 of the feeding rail 2 . The cylinders 20 at both ends of the feeding rail 2 place the steel pipes on the shelf 15 on the conveying wheels through the linkage mechanism. When the steel pipe is sent to the front pressure roller mechanism 3 on the conveying wheel, the photoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com