Engine decorative cover and cylinder cover assembly structure

An assembly structure and decorative cover technology, which is applied in the direction of engine components, engine frame, machine/engine, etc., can solve the problems of resonance between decorative cover and engine, inconvenient disassembly and assembly of engine decorative cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

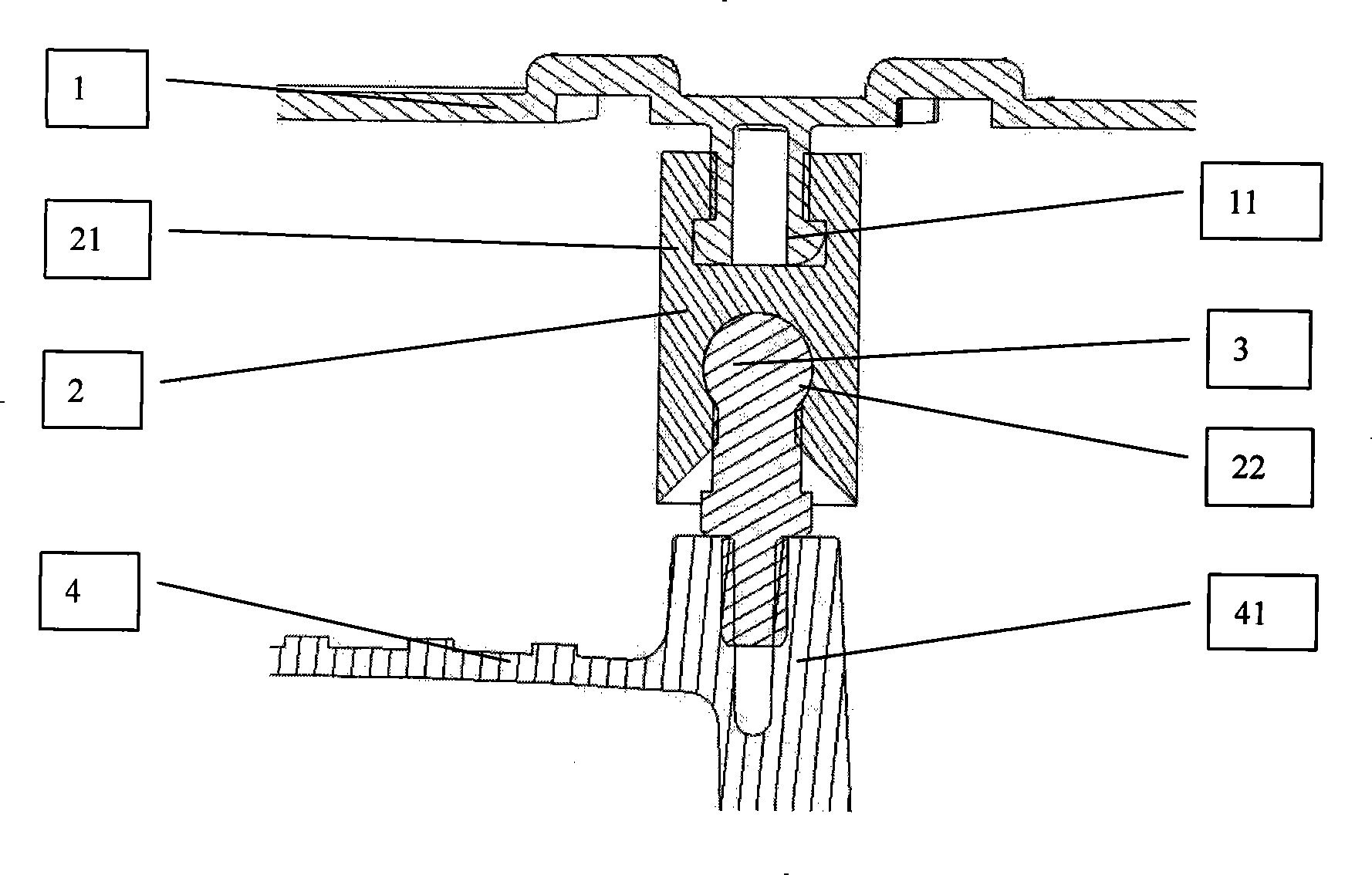

[0010] See figure 1 , The engine decorative cover and cylinder cover assembly structure includes engine decorative cover 1, rubber sleeve 2, ball head bolts 3 and cylinder cover 4. The inner side of decorative cover 1 and cylinder cover mounting boss 41 are arranged perpendicular to the surface of the decorative cover. The upper end of the rubber sleeve 2 is provided with a T-shaped groove 21 for clamping with the T-shaped boss 11, and the lower end of the rubber sleeve 2 is provided with a ball socket 22 for clamping with the ball bolt 3. During installation, the T-shaped boss 11 of the decorative cover is clamped with the T-shaped slot 21 of the rubber sleeve, and the T-shaped structure of the boss is used to clamp the rubber sleeve, so that the decorative cover 1 and the rubber sleeve 2 become a relatively fixed body. To ensure that the rubber sleeve is not separated from the decorative cover when the user disassembles the decorative cover. The ball head bolt 3 is pre-assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com