Vacuum arc-extinction porcelain shell component and its making technology

A vacuum interrupter and porcelain shell technology, applied in electrical components, high-voltage air circuit breakers, electrical switches, etc., can solve problems such as shielding cylinder falling off, power grid blackout, environmental pollution, etc., to improve production efficiency and strong breakdown resistance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

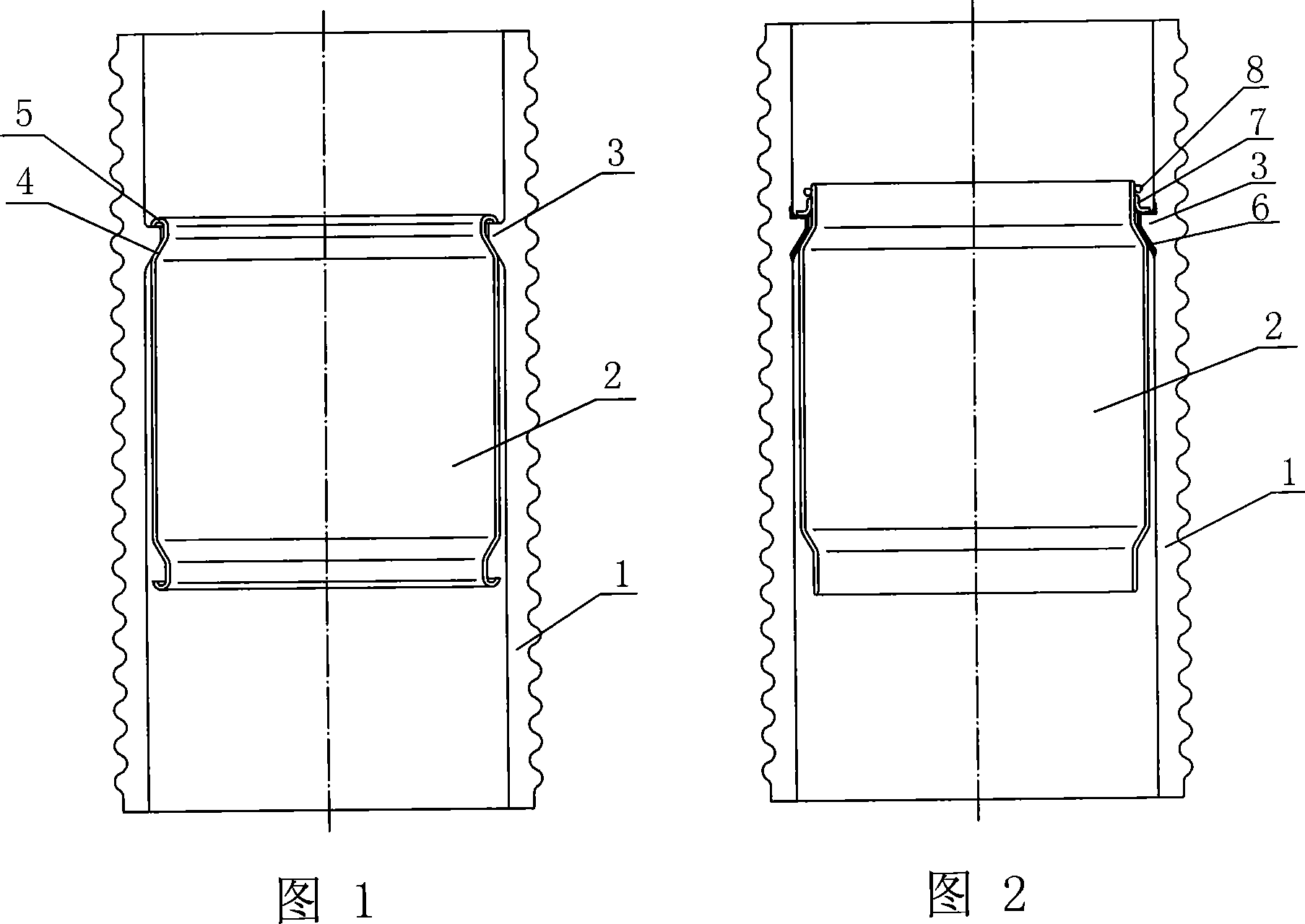

[0012] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0013] As shown in Fig. 1, the vacuum interrupter porcelain shell assembly according to the present invention has a porcelain shell 1 and a shielding cylinder 2, the inner wall of the porcelain shell 1 is provided with a fixing rib 3, and the outer edge of the shielding cylinder 2 is flanged The structural form of 5 is compressed on the fixed rib 3 to form a fixation, and the lower part of the fixed rib 3 and the corresponding position of the upper mouth of the shielding tube 2 are respectively provided with corresponding inclined contact surfaces 4 to form inclined surface contact.

[0014] During production, first put the shielding tube 2 into the porcelain shell 1, make the height of the upper edge of the shielding tube 2 exceed the height of the fixing rib 3 in the porcelain shell, move the shielding tube 2 upward, and make the upper mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com