Substrate cutting splitting device and method

A technology for substrates and slivers is applied in the field of substrate cutting and slicing devices, which can solve the problems of manpower and time consumption, and achieve the effects of reducing the burden and reducing the cost of artificial slicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

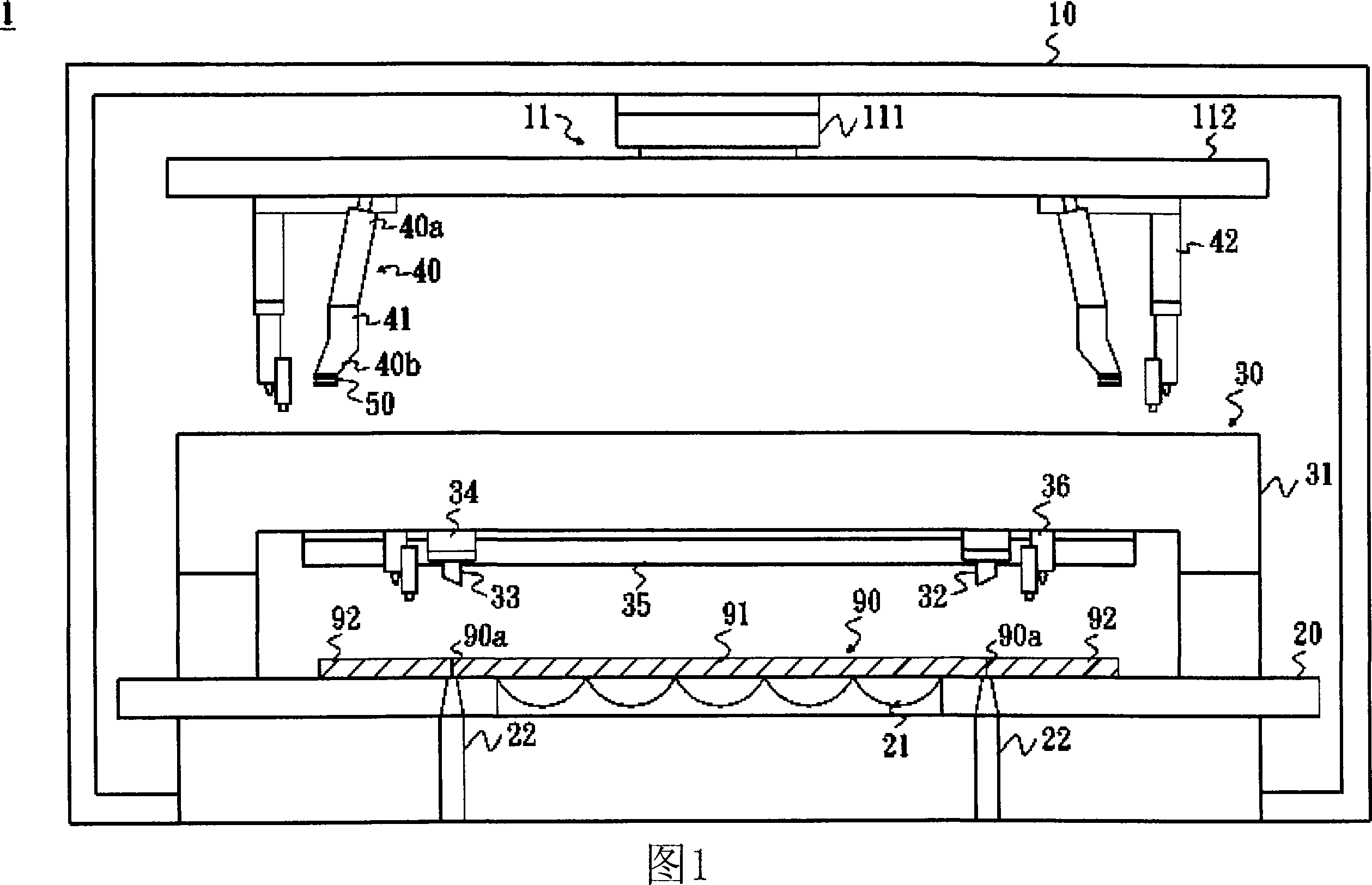

[0052] FIG. 1 is a schematic diagram of a substrate cutting and splitting device of the present invention. The substrate cutting and splitting device 1 includes: a frame body 10 , a mounting table 20 , a cutting unit 30 , a connecting arm 40 and a suction nozzle 50 .

[0053] The frame body 10 is approximately a rectangular frame, and a rotating mechanism 11 is provided on the top. The rotating mechanism 11 is provided with a rotating unit 111 and an arm 112 . The rotating unit 111 is connected to the frame body 10 and can drive the arm 112 to rotate.

[0054] The mounting platform 20 is located in the frame body 10 for carrying the substrate 90 . The stage 20 is provided with a plurality of adsorption elements 21 , which can absorb the substrate 90 by vacuum, so that the substrate 90 is fixed on the stage 20 without shaking or shifting. The substrate 90 can be made of glass, but not limited thereto, and those skilled in the art can also select an appropriate substrate materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com