Method for preparing micro ice crystal cell disruption reinforced by ultrasound wave and defoaming by centrifugation

A technology of cell fragmentation and production method, which is applied in food preparation, food forming, food science and other directions, and can solve the problems of not being released, nutrients being destroyed, and the inability to fully release the nutrients of vegetables and fruits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

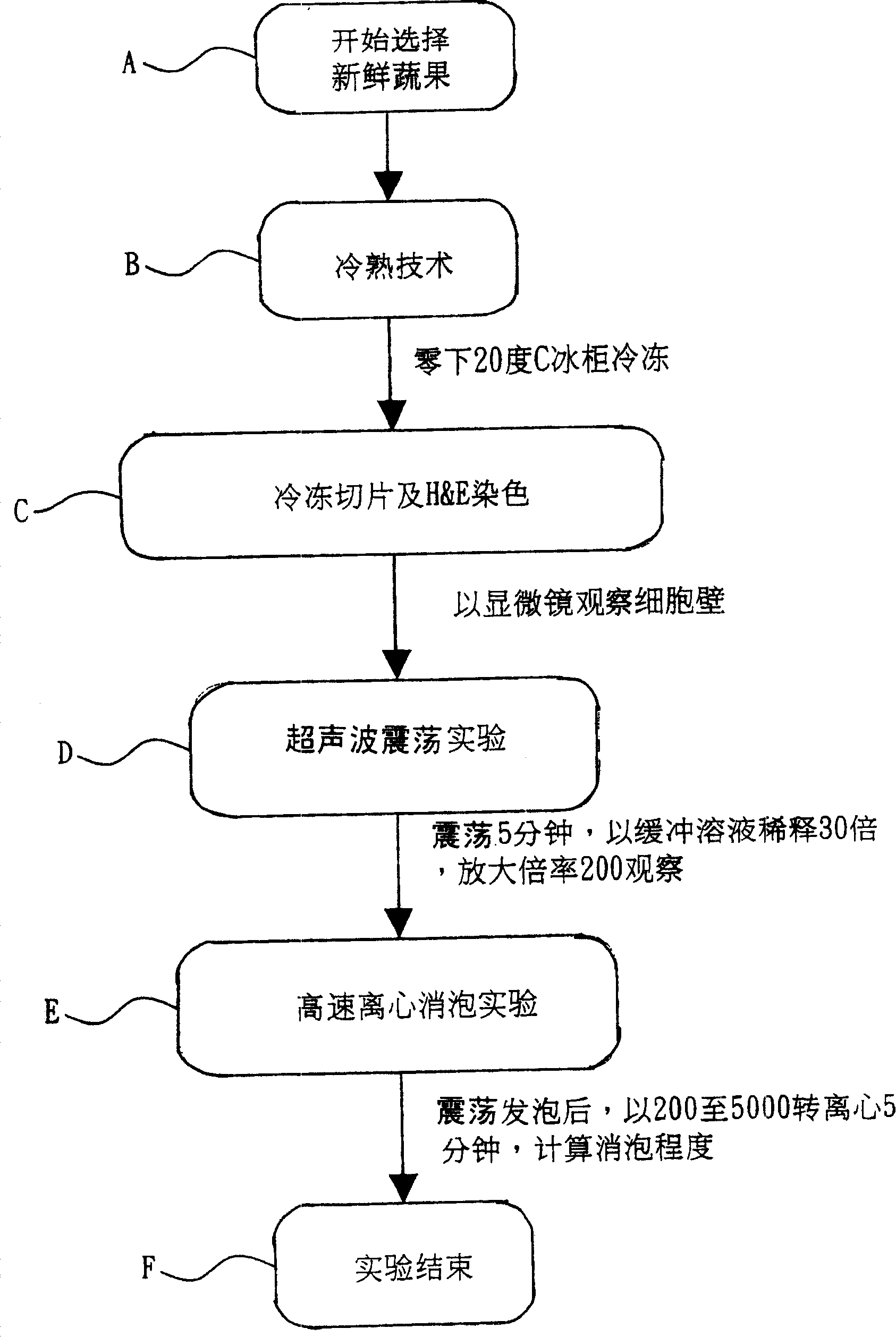

[0035] In the present invention, the ultrasonic-strengthened micro-ice crystal cell crushing and centrifugal defoaming method, wherein, the ultrasonic-strengthened micro-ice crystal cell crushing and centrifugal defoaming, the steps of the method for extracting vegetable and fruit nutrients are as follows:

[0036] A. Start: choose fresh fruits and vegetables;

[0037] B. Cold ripening treatment: freeze the fruits and vegetables at a temperature lower than the eutectic point, and in the frozen state, the water in the cells forms ice crystals to break the cell walls;

[0038] C. Frozen sectioning and whipping: directly cut and whipped in a frozen state;

[0039] D. Ultrasonic vibration to strengthen the crushing effect: use frequency conversion ultrasonic vibration for several minutes, and the bubble explosion generated by the vibration can further break the cells;

[0040] E. High-speed centrifugal defoaming: centrifugal treatment with multi-stage speed, for example, 5 kinds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com