Tip dresser

A grinding machine, electrode technology, applied in the direction of electrode characteristics, electrode maintenance, manufacturing tools, etc., can solve the problems of different conditions, unable to suppress the radial vibration of the electrode head, etc., to achieve the effect of preventing radial vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

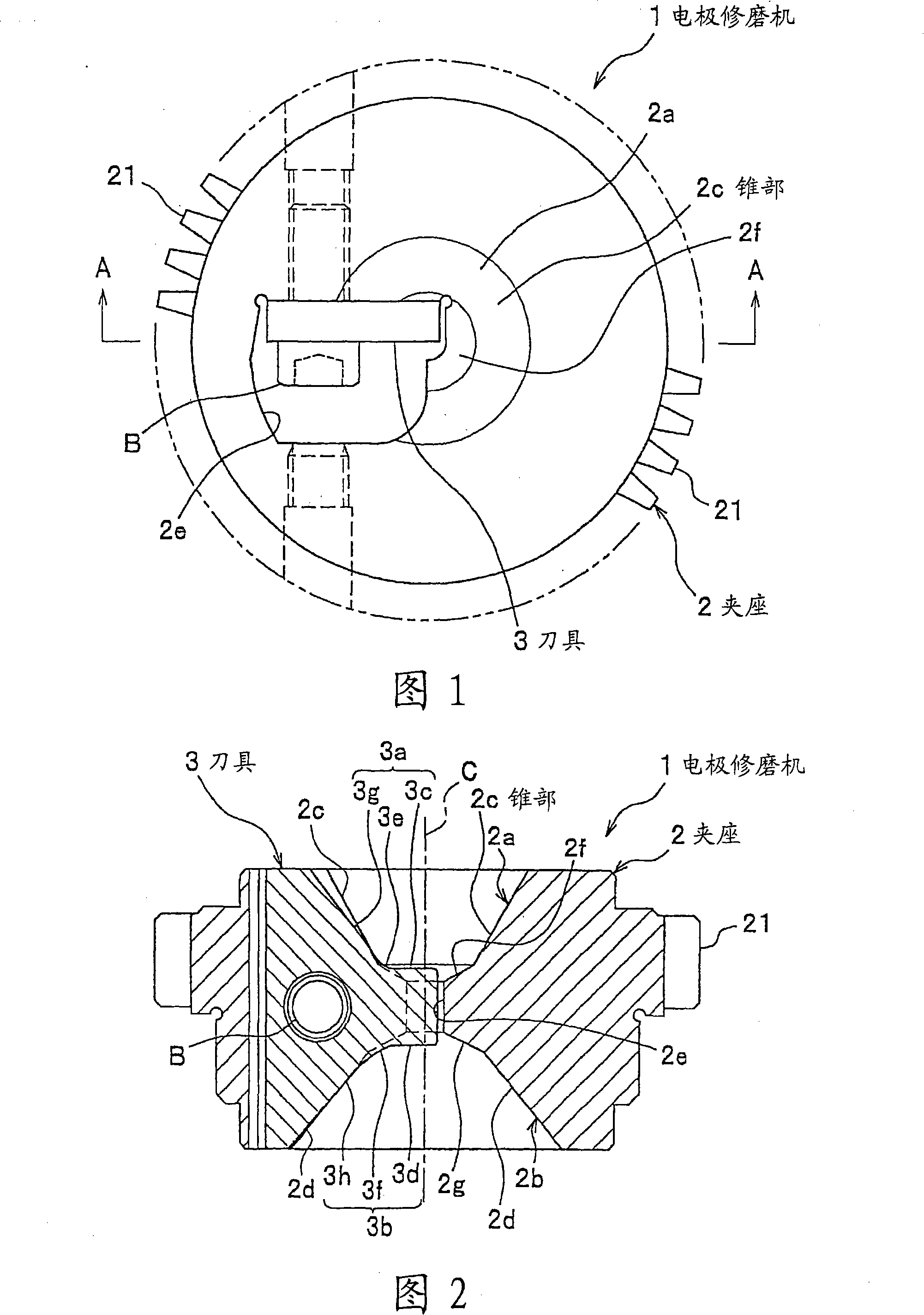

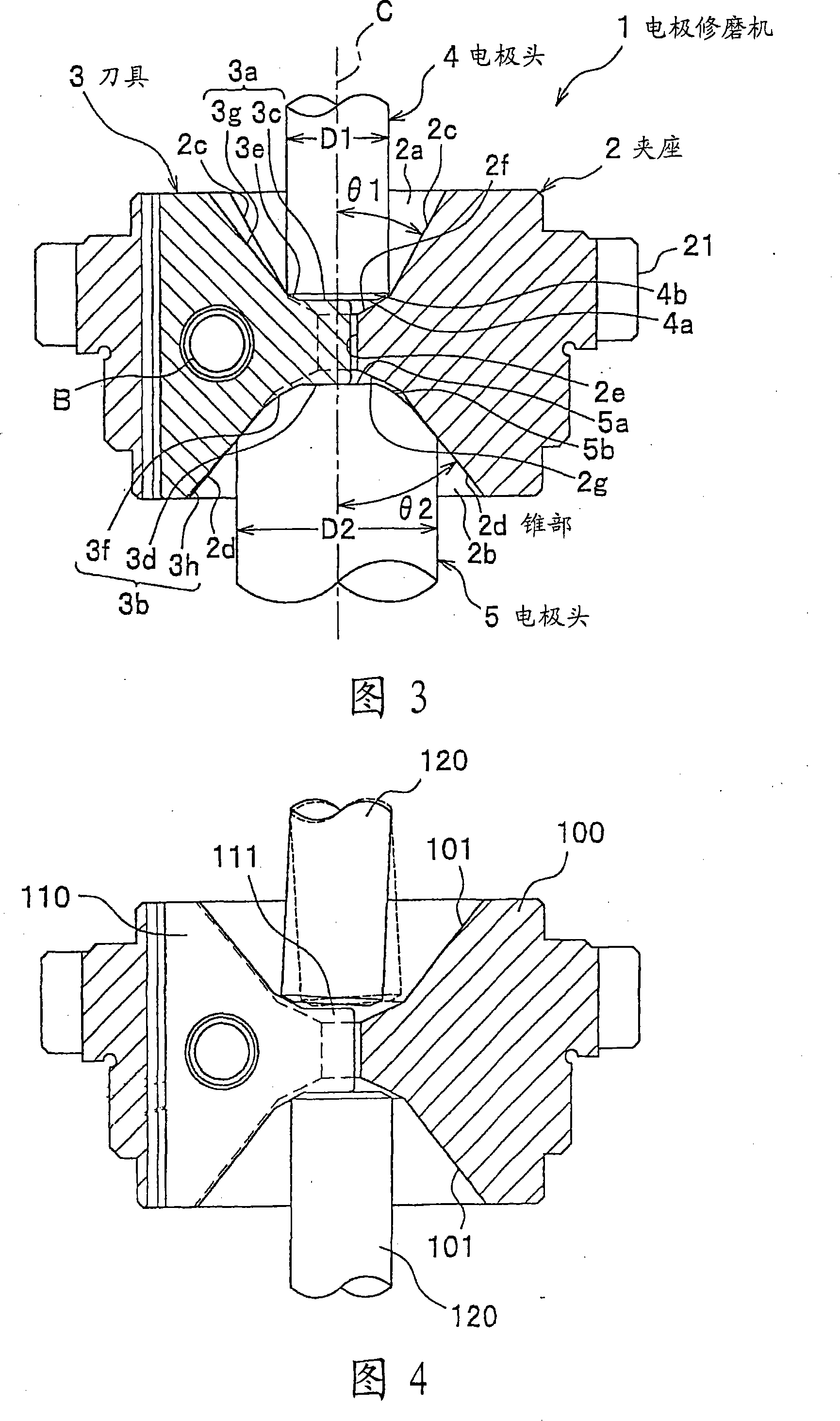

[0026] Hereinafter, an embodiment of the present invention will be described in detail with reference to FIGS. 1 to 3 .

[0027] FIG. 1 is a plan view of an electrode dresser according to an embodiment of the present invention. Fig. 2 is a cross-sectional view along line A-A of Fig. 1 . 3 is a cross-sectional view showing a state in which an electrode tip is cut by the dresser according to the embodiment of the present invention.

[0028] (Structure of electrode dresser)

[0029] The electrode dresser 1 shown in FIG. 1 is a device as follows: a motor (not shown) using compressed air, oil pressure, and electricity as a driving source is connected to a chuck 2 via a transmission gear (not shown). The integral gear 21 rotates, and the tip end portions of the electrode tips 4 and 5 (see FIG. 3 ) are cut and shaped by the cutter 3 attached to the holder 2 .

[0030] (Clamp structure)

[0031] As shown in FIGS. 1 and 2 , the holder 2 is a member for holding the tool 3 and rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com