Brush manufacturing machine

A technology for manufacturing machines and brushes, which is applied in the direction of brushes, brush bodies, household appliances, etc., which can solve the problems of high cost and achieve the effect of fast conveying movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

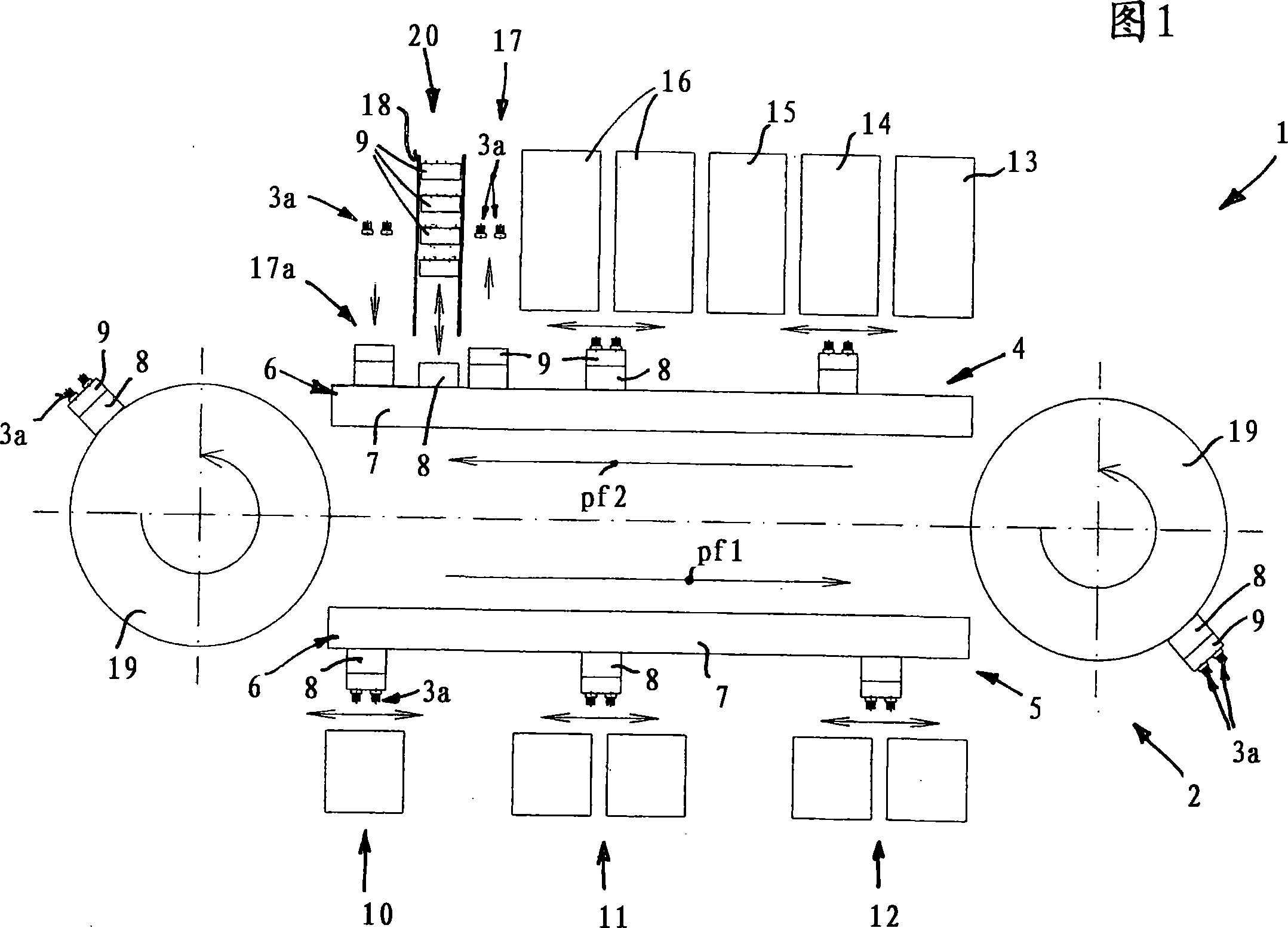

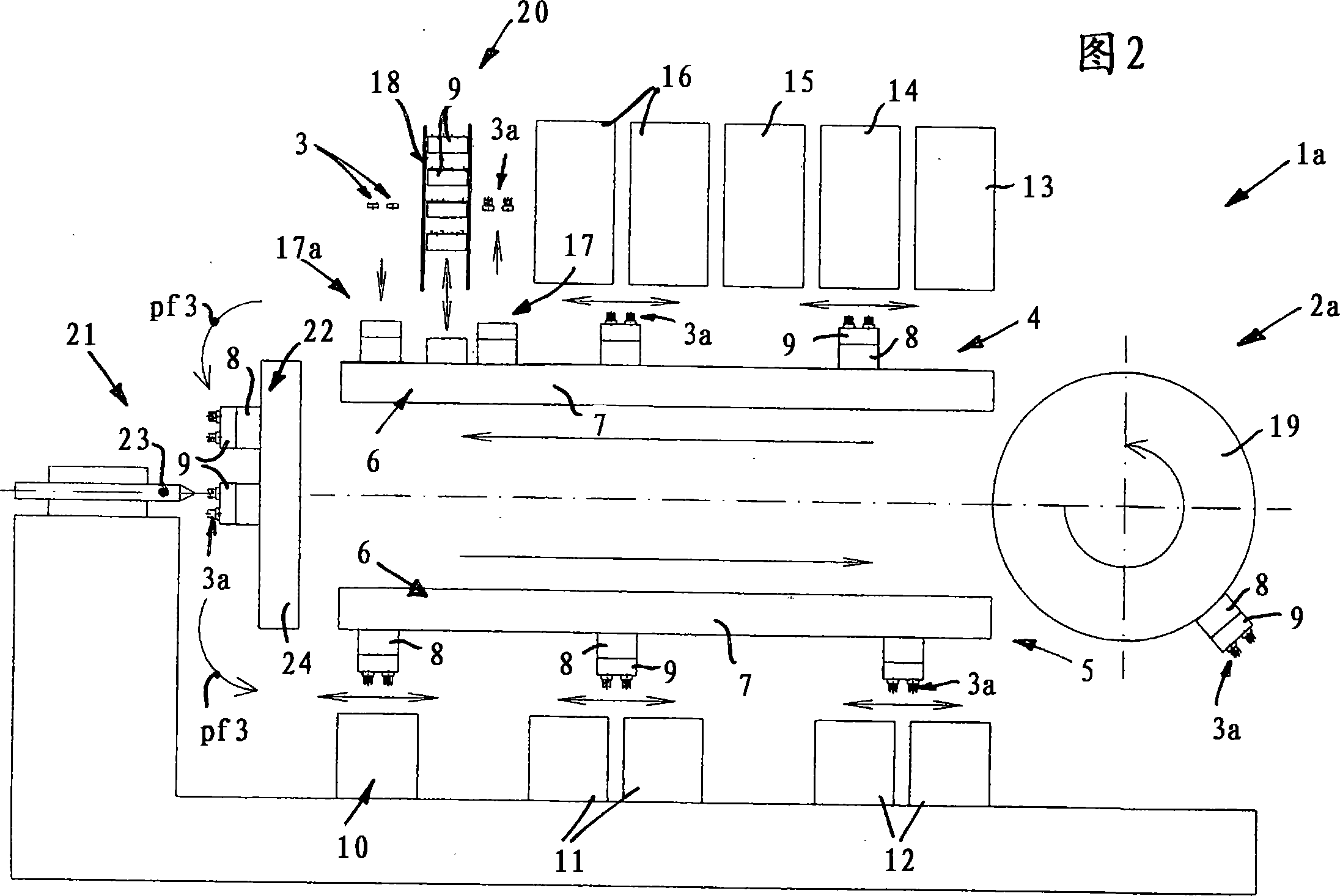

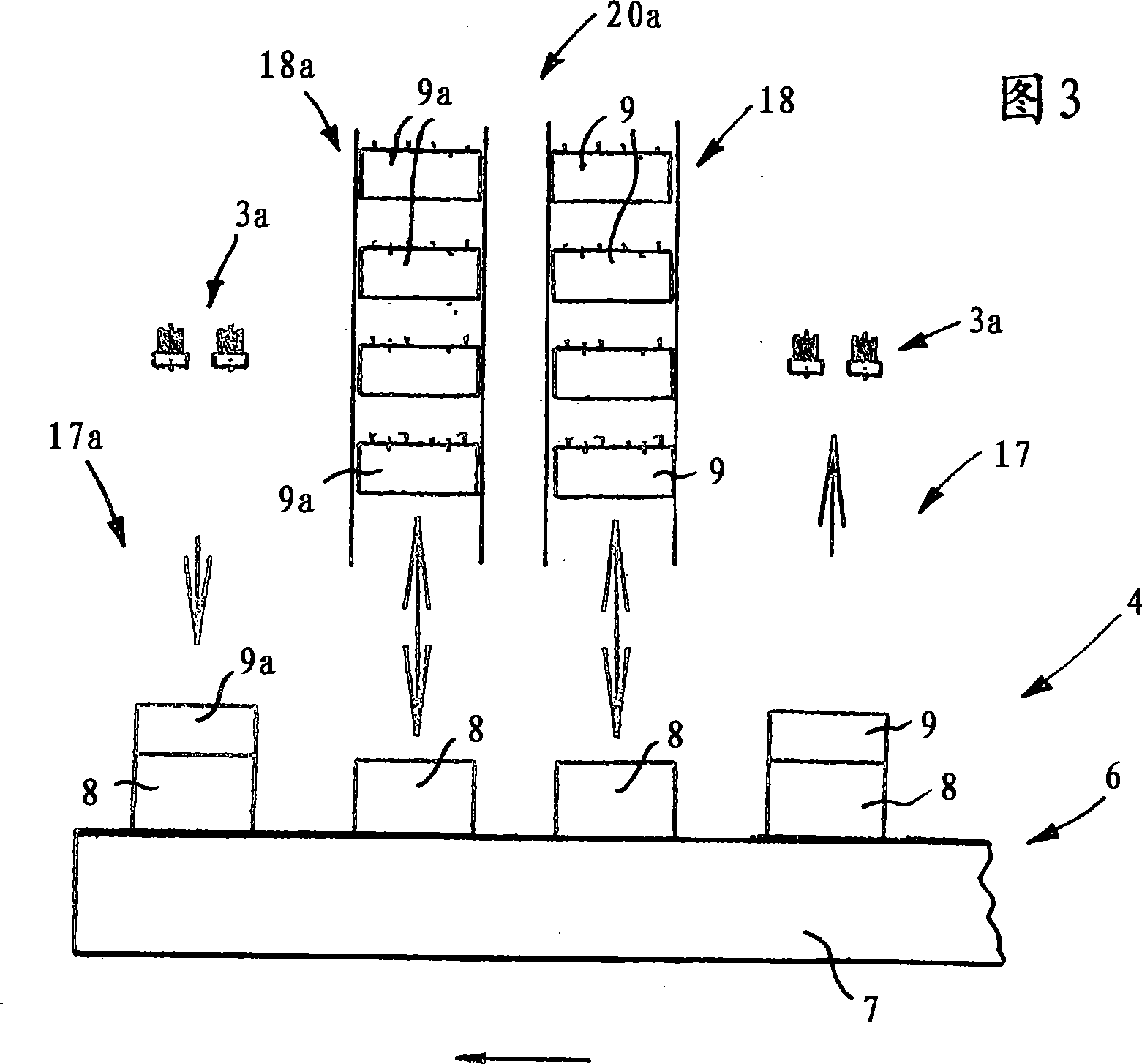

[0025] The brush production machine 1 shown in FIG. 1 has a conveyor 2 for brushes 3a, wherein processing stations are arranged along the conveyor. The conveying device 2 is designed as an endless conveying device and has two conveying parts 4 and 5 arranged approximately parallel to one another in the exemplary embodiment, each having at least one linear motor 6 .

[0026] The linear motors 6 each have a stator 7 extending substantially along the conveying section, on which a plurality of runners 8 are movable independently of one another.

[0027] Each mover 8 is air-bearing, so that it moves without contact and without wear via an air cushion formed between the mover and the stator.

[0028] Since the movers 8 are held magnetically on the stator 7, an arbitrary configuration and thus an overhead configuration of the linear motor is also possible. There is thus a high degree of flexibility in the construction of the brush manufacturing machine, since its position can be ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com