Door handle mounting structure

A technology for door handles and structures, which can be used in the direction of handle connections, lock casings, door/window accessories, etc., and can solve problems such as door sags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

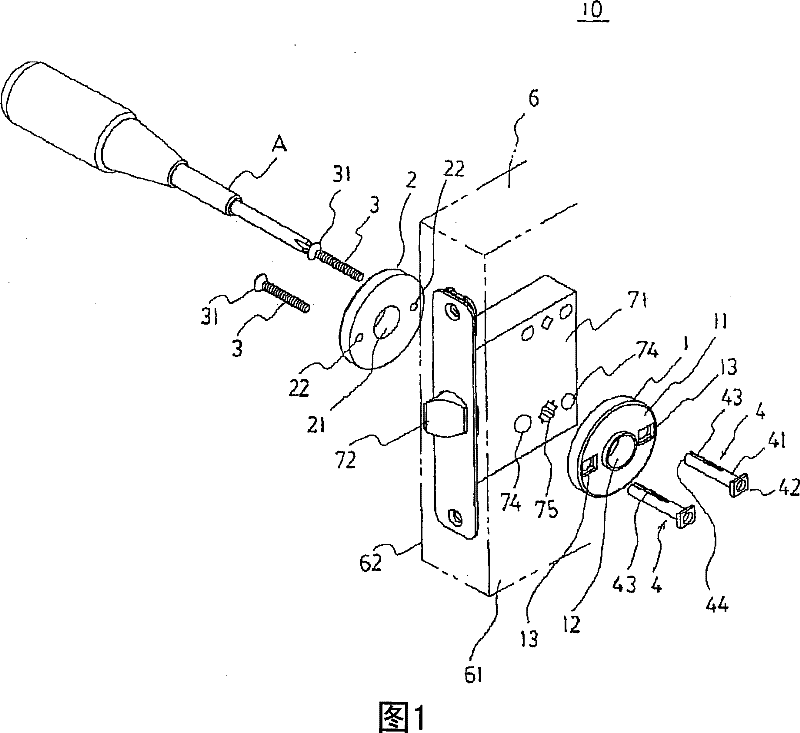

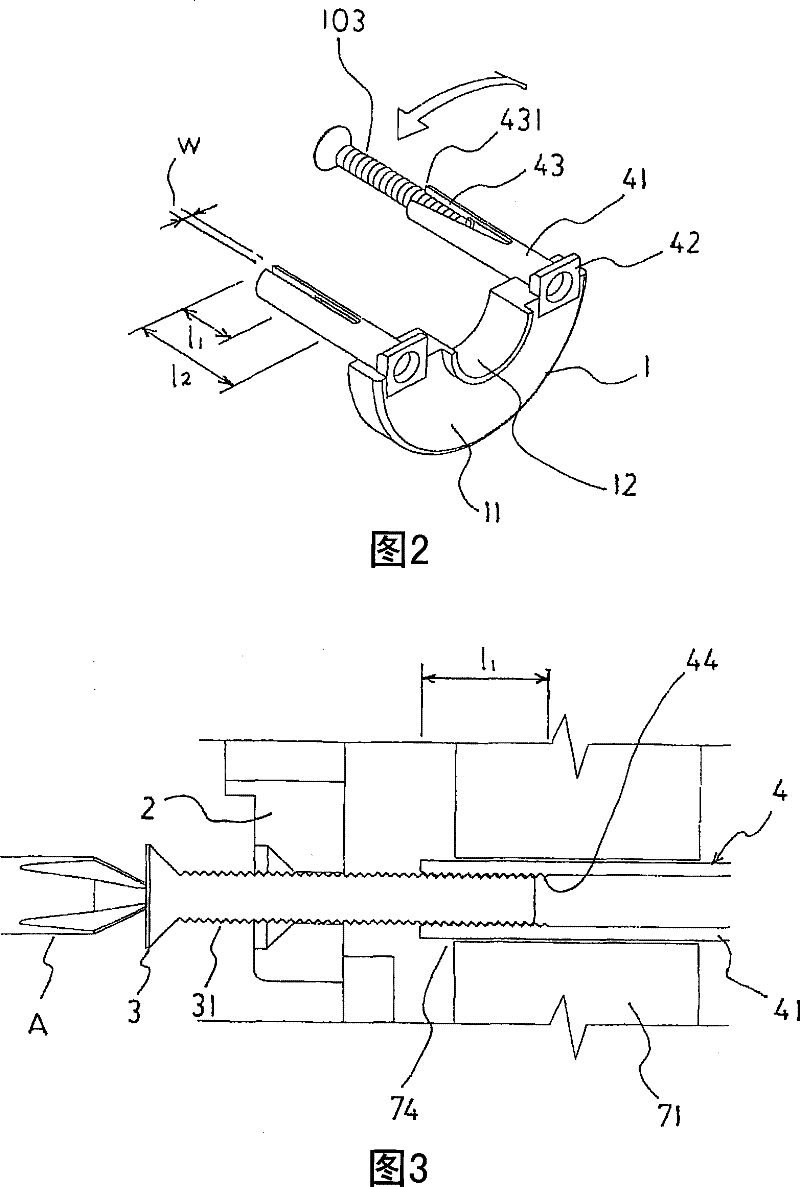

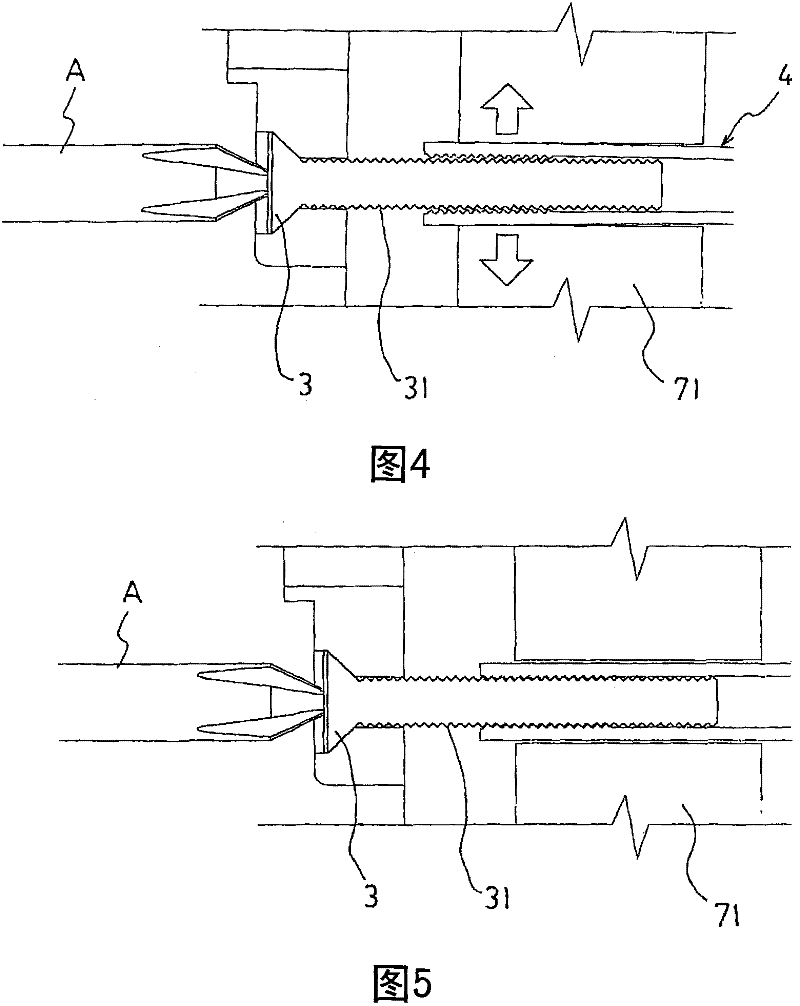

[0023] Below, will refer to Figure 1 to Figure 6 The door handle mounting structure (hereinafter, simply referred to as "mounting structure") according to the first embodiment of the present invention will be described in detail. figure 1 It is a figure explaining the situation of installing the installation body structure on the door, figure 2 It is a diagram showing the state where a screw is screwed into the threaded hole for screw thread connection of the screw sleeve, image 3 It is a schematic diagram showing the initial state of a small screw screwed into the threaded hole for screw thread connection of the screw sleeve, Figure 4 It is a schematic diagram showing the meshing state of the screw when the small screw is fastened and the slit is opened, Figure 5 is to indicate that the screw is from Figure 4 The state returns a sketch of the meshing state of a thread, Figure 6 is a plan view showing a part of the mounting structure through a section, Figure 8 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com