Brake lining arrangement for disc brakes

A technology of disc brakes and brake linings, applied in the direction of brake components, brake types, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

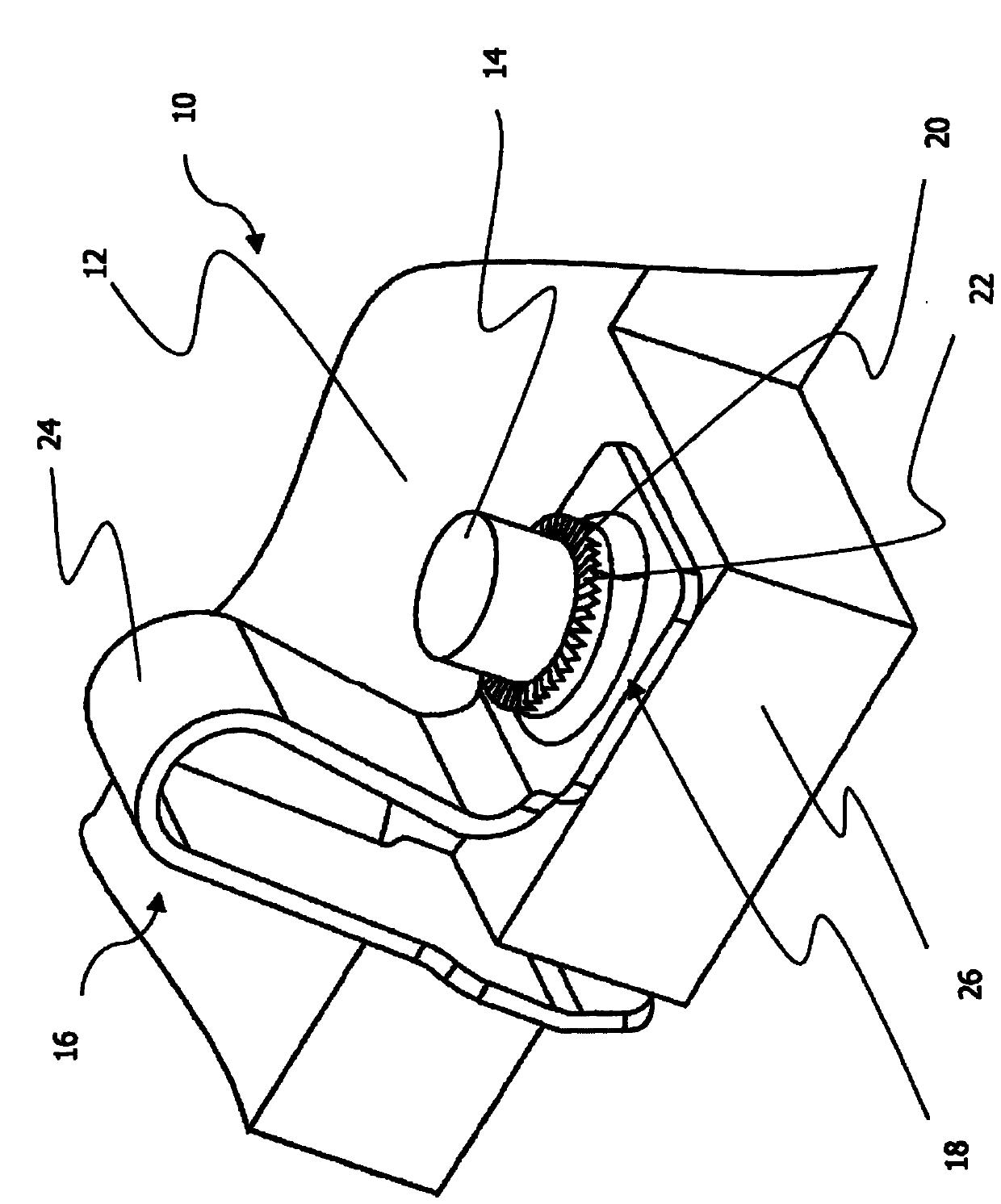

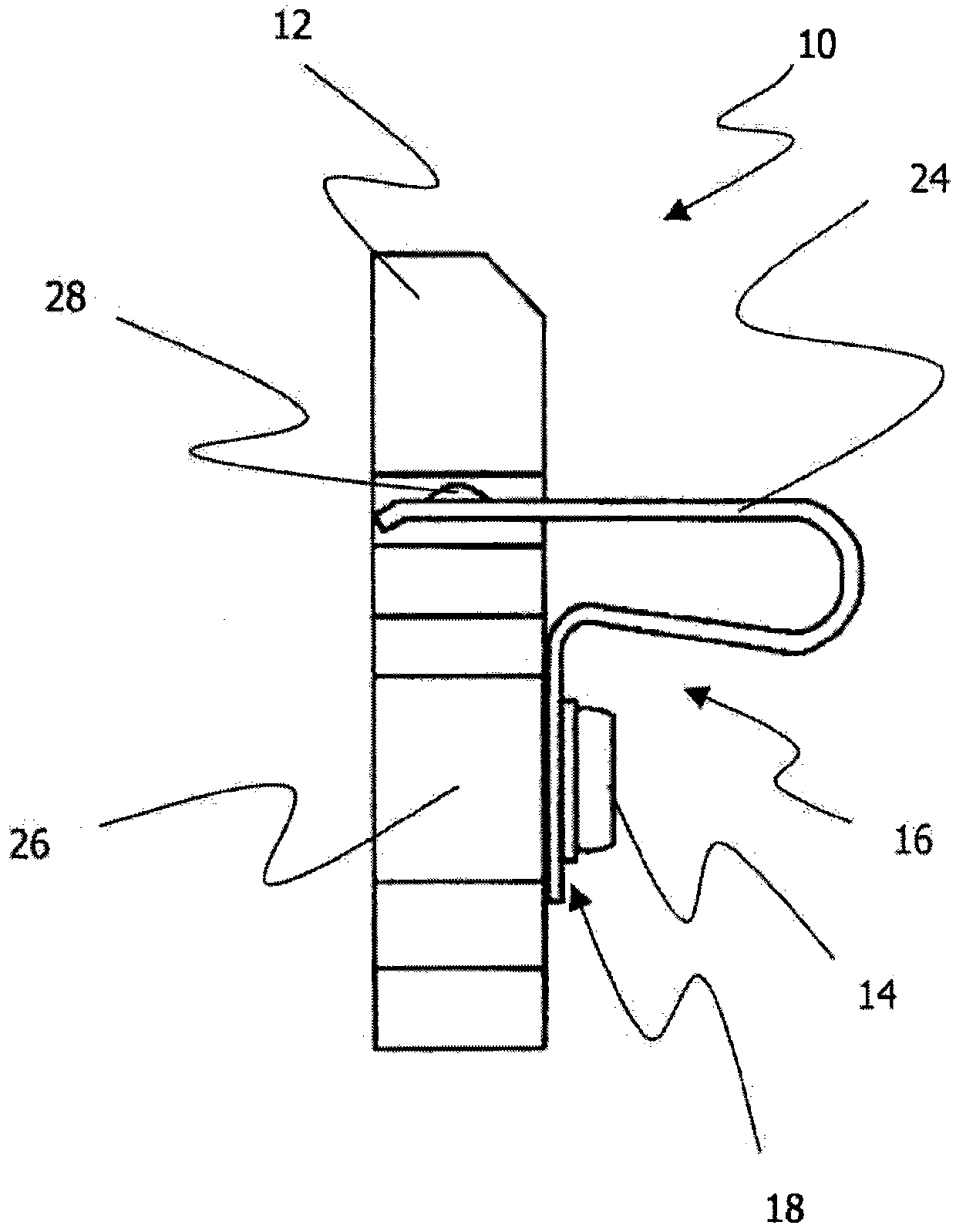

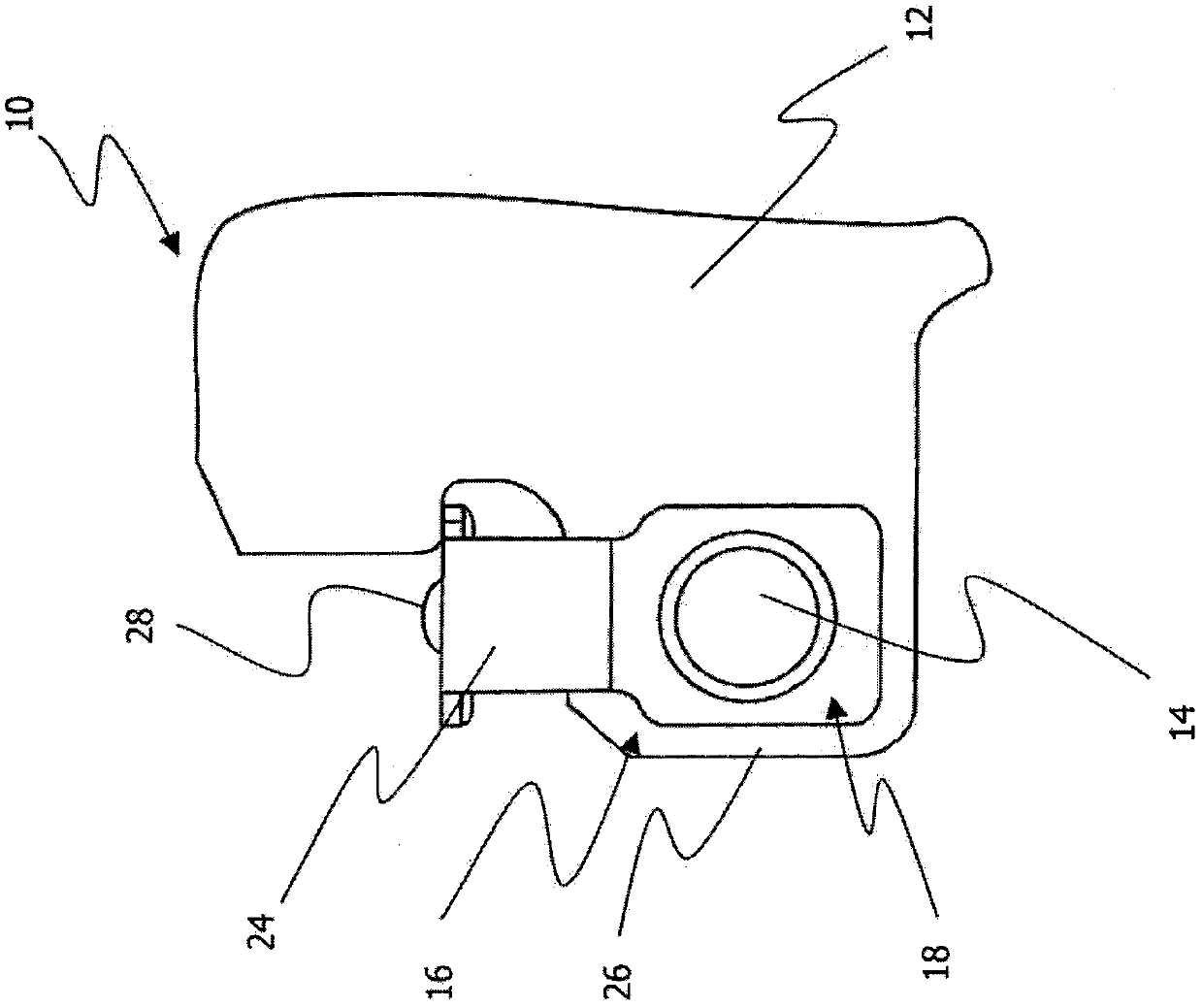

[0017] figure 1 The brake lining arrangement 10 with the spring element 16 and the spring pin 14 arranged on the back of the brake lining 12 is shown after the riveted fastening of the spring pin 14 . from figure 1 The fastening part 18 of the spring element 16 can be seen more clearly in the figure, which fastening part 18 has an irregular surface structure 22 and / or a profile at least in sections around the receiving opening 20 . The surface structure can in particular be configured in the form of sawtooth, knurling or fluting. Further provided on the spring element 16 is an arcuate portion 24 , by means of which the brake lining arrangement 10 can be fastened to a brake piston (not shown) of a disc brake.

[0018] figure 1 Also shown is a protrusion 26 to which the spring element 16 can be fastened by means of the spring pin 14 . It is more evident that the end region of the arcuate portion 24 protrudes into the cross-section of the brake lining 12 above the protrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com