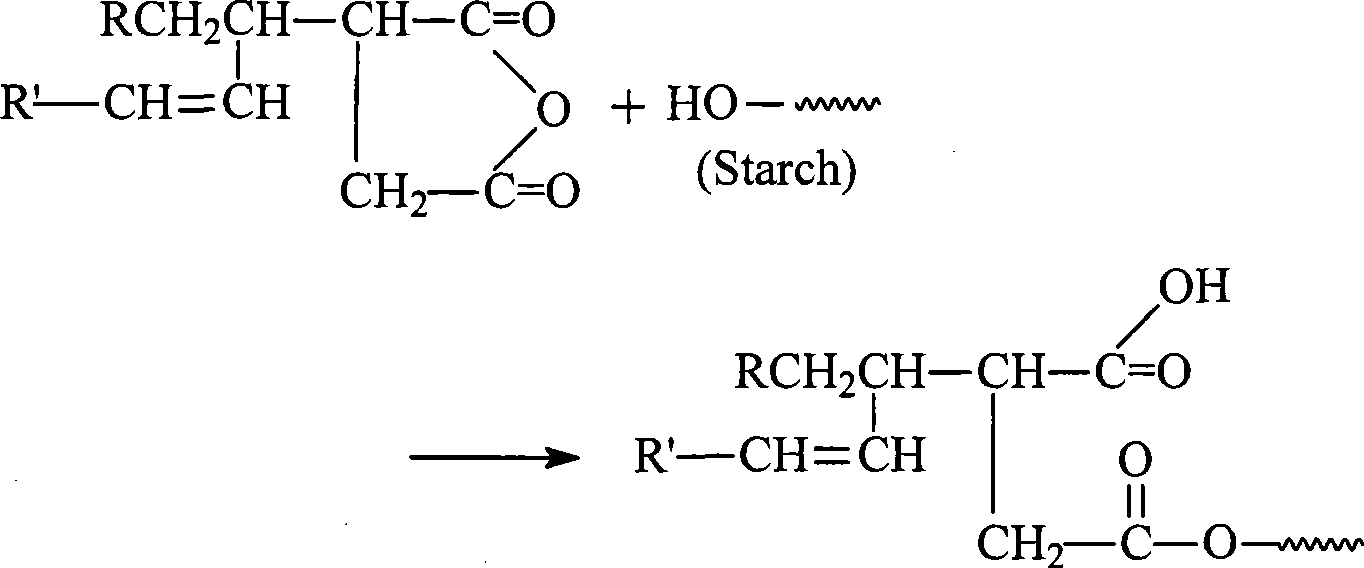

Method for preparing hydrophobic thermoplastic starch by using alkenyl succinic anhydride

A technology of alkenyl succinic anhydride and thermoplastic starch, which is applied in the field of plastic modification and can solve the problems of high price, difficulty in popularization, loss of usability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1, first cornstarch and alkenyl succinic anhydride were added to a mixer at a speed of 5000 rpm at a mass ratio of 100:0.1 and mixed for 8 minutes; then the mixture was closed and placed for 10 hours; passed through a screw plastic extruder Extruding to produce hydrophobized thermoplastic starch, wherein the extrusion temperature of the mixture from the feed port to the discharge port is 120°C-130°C-130°C-110°C in sequence.

Embodiment 2

[0010] Example 2, firstly, wheat starch and alkenyl succinic anhydride were added to a mixer at a speed of 3000 rpm in a mass ratio of 100:1 and mixed for 6 minutes; then the mixture was closed and placed for 6 hours; passed through a screw plastic extruder Extruding to produce hydrophobized thermoplastic starch, wherein the extrusion temperature of the mixture from the feed port to the discharge port is 120°C-130°C-130°C-110°C in sequence.

Embodiment 3

[0011] Embodiment 3, at first sweet potato starch and alkenyl succinic anhydride are joined in the mixer that rotating speed is 1000 revs / min by the mass ratio of 100:4 and mix for 2 minutes; Then the mixture is closed and placed for 12 hours; Extruding to produce hydrophobized thermoplastic starch, wherein the extrusion temperature of the mixture from the feed port to the discharge port is 120°C-130°C-130°C-110°C in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com