Dried noodle machine

A noodle machine and noodle technology, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of skewed noodles, high equipment cost, difficult precision, etc., to achieve smooth turning operation, improve efficiency, and reduce operation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

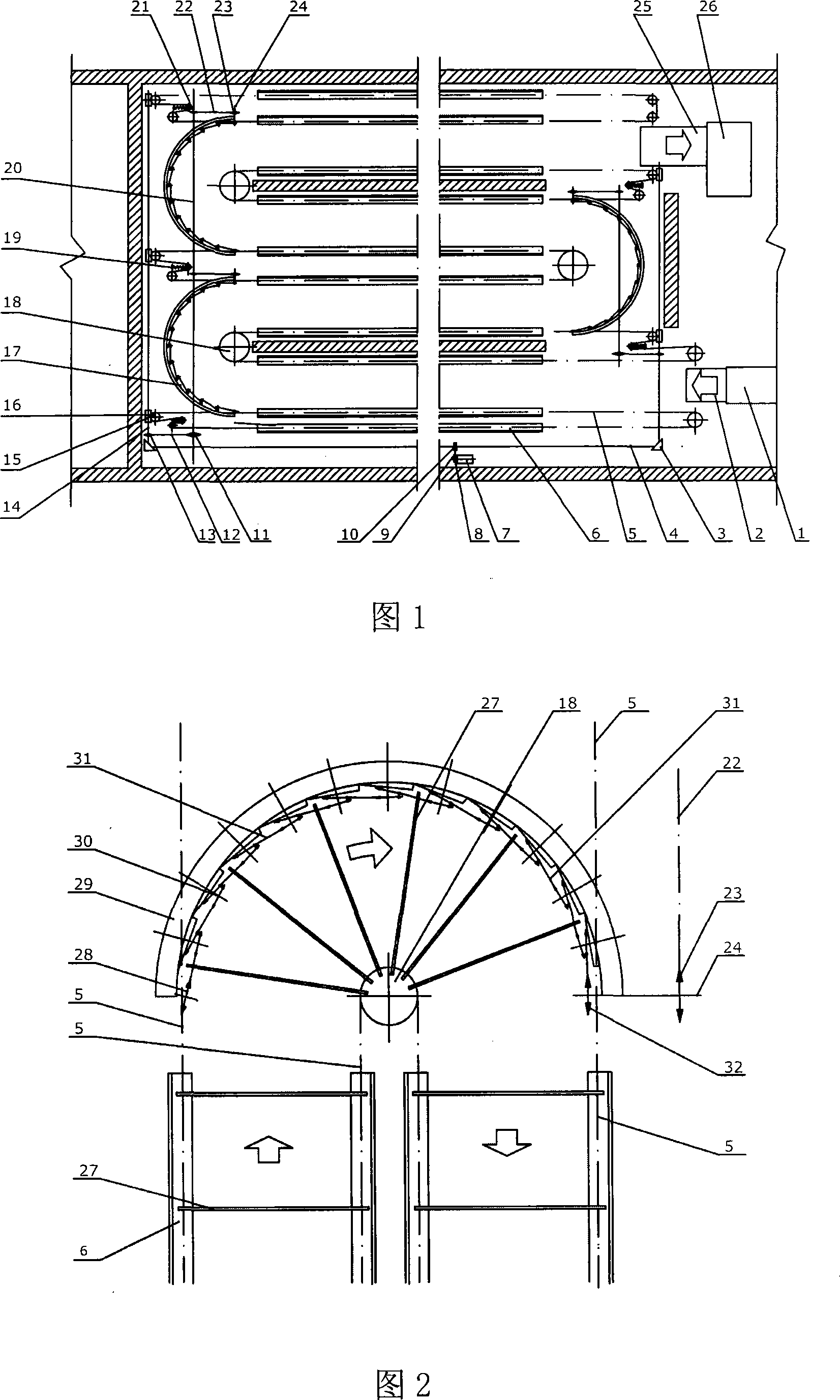

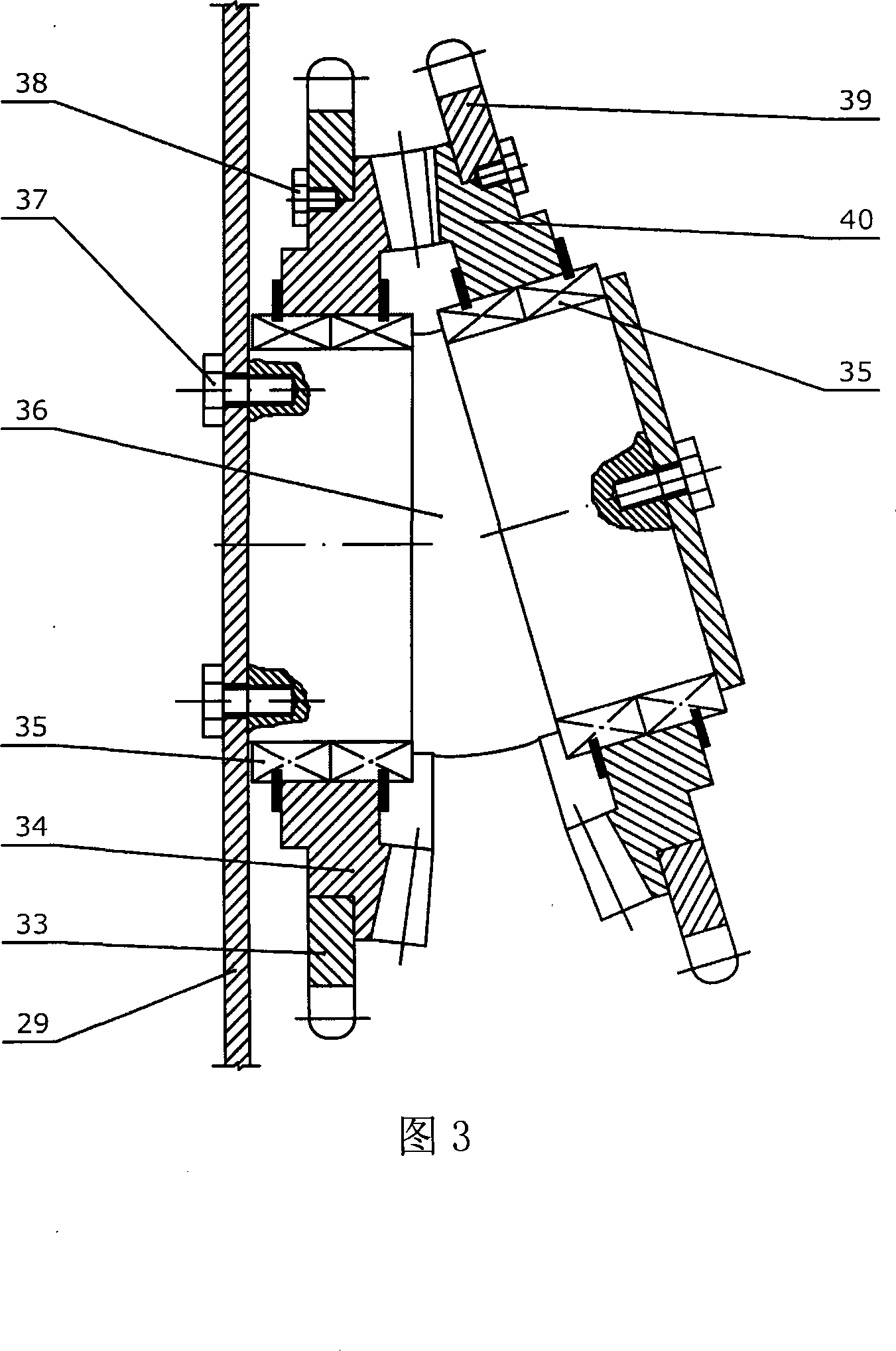

[0013]As the embodiment of the noodle drying noodle rod turning mechanism in the noodle drying chamber of the noodle machine of the present invention, it is shown in the accompanying drawings 1 to 3 . Below in conjunction with accompanying drawing 1~Fig. 3, the structure of the present invention and its operating process are described in more detail. The dried noodle machine of the present invention comprises a dried noodle drying device in a dried noodle drying chamber, the dried noodle drying device comprises a drying conveying chain, a transmission system, a noodle rod steering mechanism, a noodle rod hanging and unloading mechanism, and the dried noodle drying indoor noodle rod turns to The mechanism is that the outer end turning device 17 of the noodle bar and the inner end turning supporting sprocket 18 of the noodle bar are installed on the turning part of the noodle bar, and more than two groups of The gear chain wheel assembly 30 is connected with the turning relay ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com