Pipe type incandescent lamp

A technology for incandescent lamps and tubes, applied in the direction of incandescent lamps, incandescent lamp parts, electrical components, etc., can solve the problems of inconsistent heating of printing media, no positioning part, and inability to configure tube-type incandescent lamp extensions, etc., to ensure strength, Prevent damage, prevent unfixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

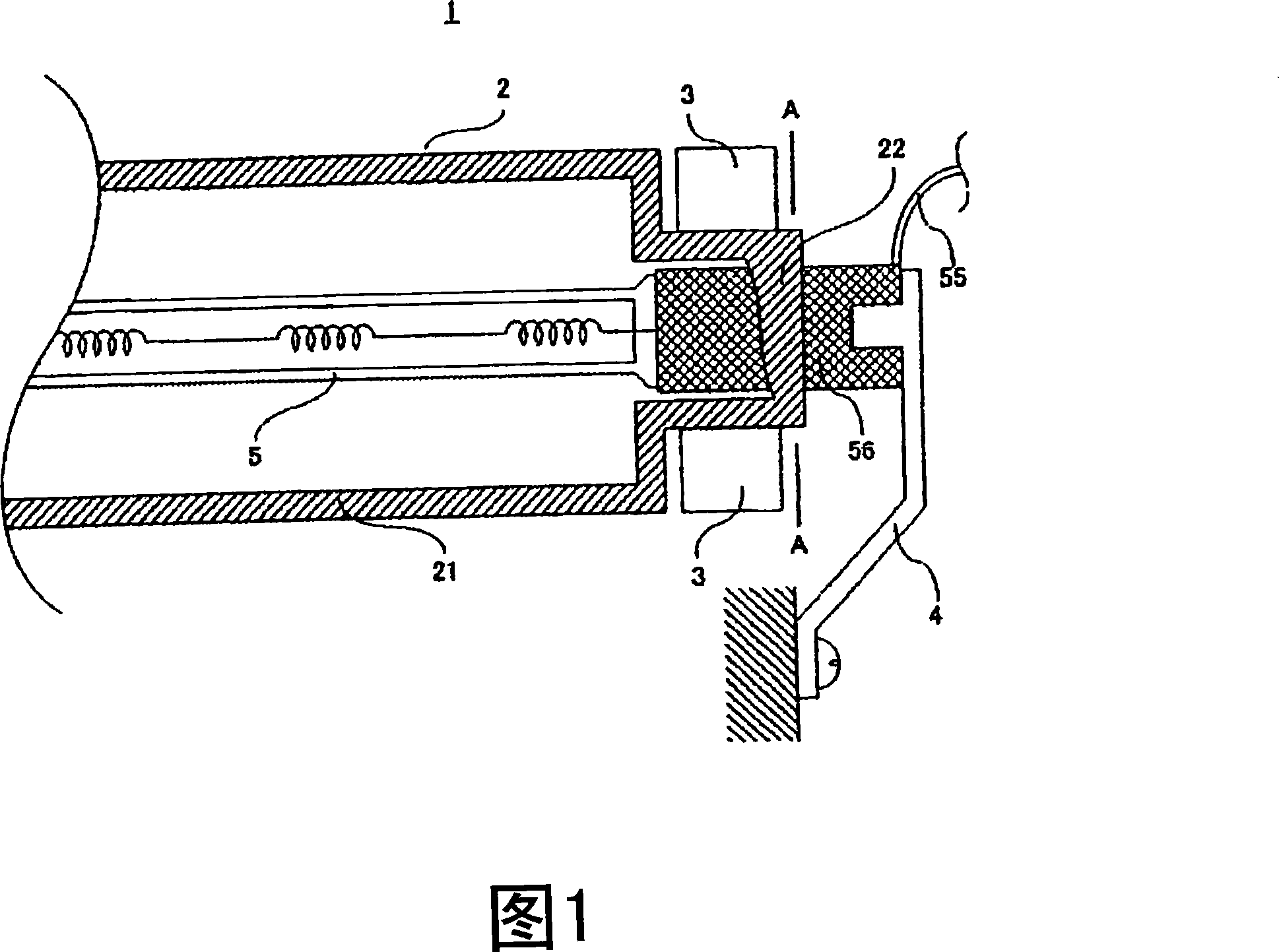

[0074] An example of a printer fixing device 1 according to the present invention will be described with reference to FIG. 1 .

[0075] FIG. 1 is a side view of a longitudinal end portion of a fixing device 1 of a printer, and a part of a fixing roller 2 is removed to illustrate the inside thereof. The same reference numerals are assigned to the same components as those shown in FIG. 12 . Also, the pressure roller is omitted.

[0076] The printer fixing device 1 includes a pressure roller (not shown), a fixing roller 2 , a rotation gear 3 , a tube-shaped incandescent lamp 5 , and a fixing member 4 . The description about the pressure roller is omitted.

[0077] A cylindrical fixing roller 2 is disposed in the printer fixing device 1 . The fixing roller 2 includes: a cylindrical radially enlarged portion 21 that expands in the radial direction; a cylindrical radially reduced portion 22 whose end portion is radially reduced relative to the radially enlarged portion 21 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com