Pool type sodium cooled fast reactor accident afterheat exhausting system

A sodium-cooled fast reactor and exhaust system technology, which is applied to reactors, cooling devices, and greenhouse gas reduction, and can solve problems such as poor passive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

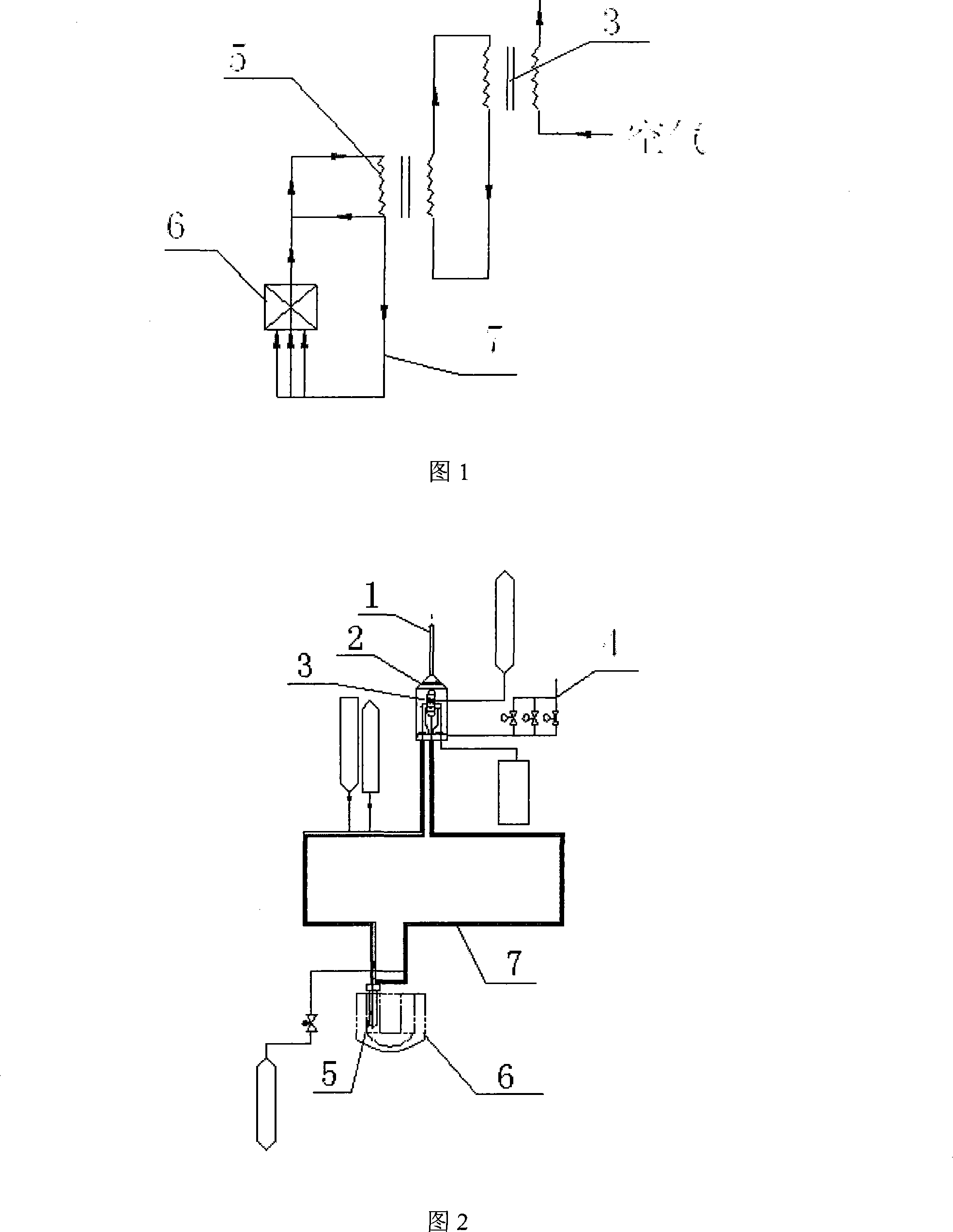

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] As shown in Figures 1 and 2, the present invention consists of two mutually independent loops with the same structure, and each loop can effectively ensure the discharge of the remaining heat release of the reactor core. Each loop is composed of an independent heat exchanger 5, an air heat exchanger 3, a double-layer main pipeline 7 with electric heating wire and insulation layer, and measuring and controlling instruments. The independent heat exchanger 5 and the air heat exchanger 3 are connected in series, the lower part of the independent heat exchanger 5 is immersed in the sodium pool of the reactor core, and the air heat exchanger 3 is connected with the draft chimney 1 outside.

[0016] Wherein, the independent heat exchanger 5 is an immersed passive sodium-sodium heat exchanger. It includes a safety shell, an outer tube is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com