Light valve module

A light valve and opto-mechanical technology, applied in the field of projectors, can solve the problems of poor contact, falling off, and inability to control the DMD chip correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings. Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals. In addition, here we first define a component whose side facing the optomechanical base is the front side, and the side facing away from the optomechanical base is the rear side.

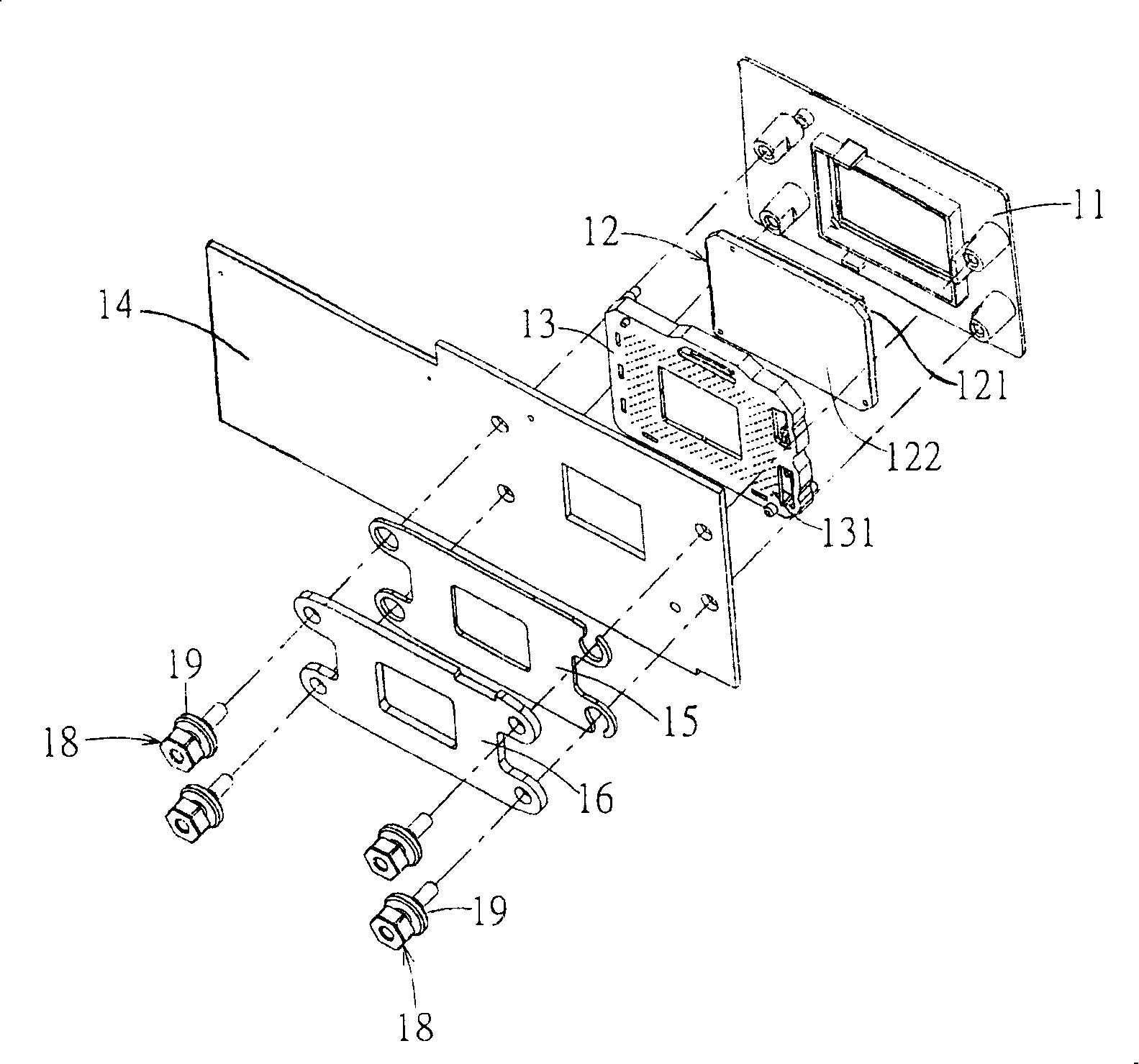

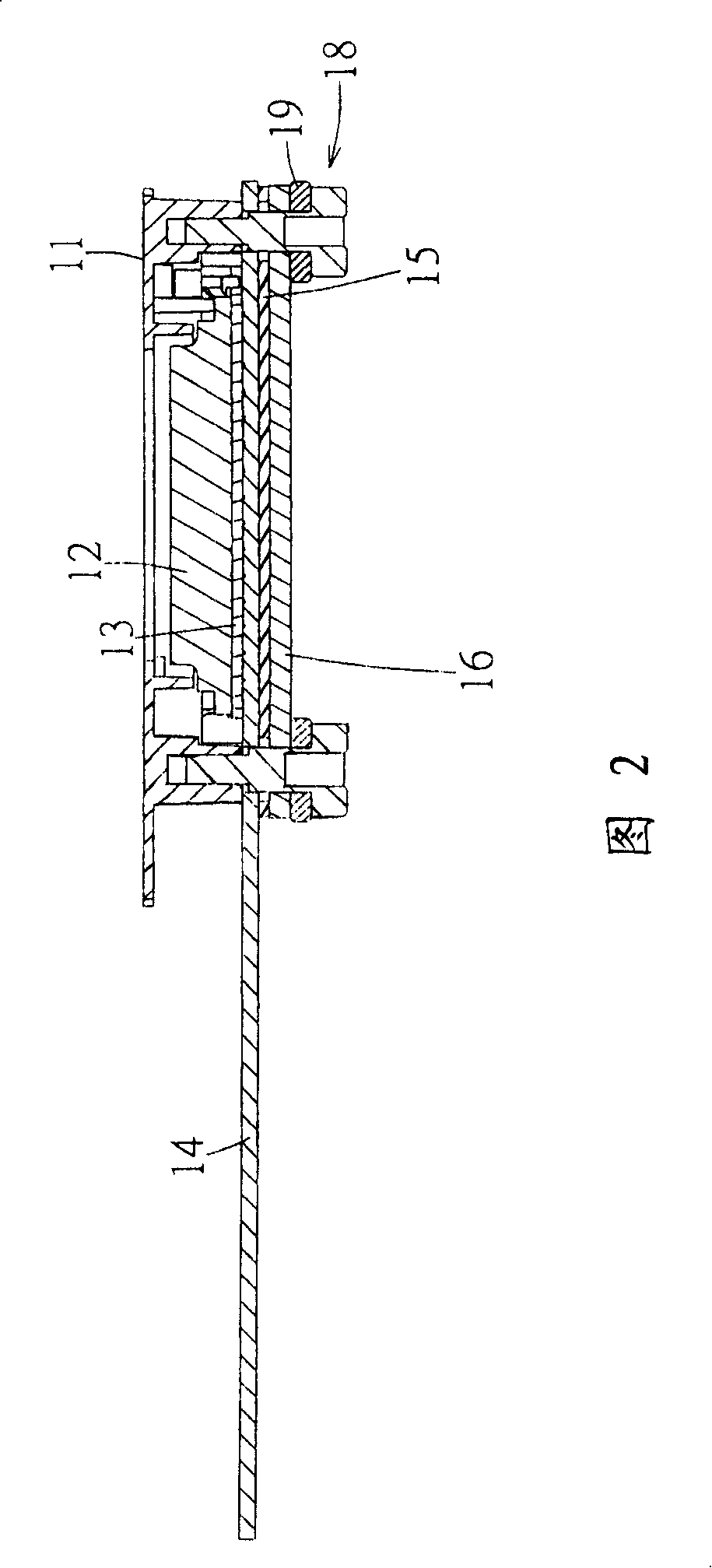

[0059] refer to image 3 As shown in FIG. 4 , the light valve module according to an embodiment of the present invention includes a display element, a seat 4 , a circuit board 5 , a buffer sheet 6 , and a rigid board 7 . The light valve module is suitable for being assembled on an optical machine base 2 by a plurality of screws 8, and the optical machine base 2 has a plurality of fixing parts 21. In this embodiment, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com