Motherboard of display panel and production method thereof

A technology for display panels and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as the limitation of motherboard utilization, and achieve the effect of improving motherboard utilization and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

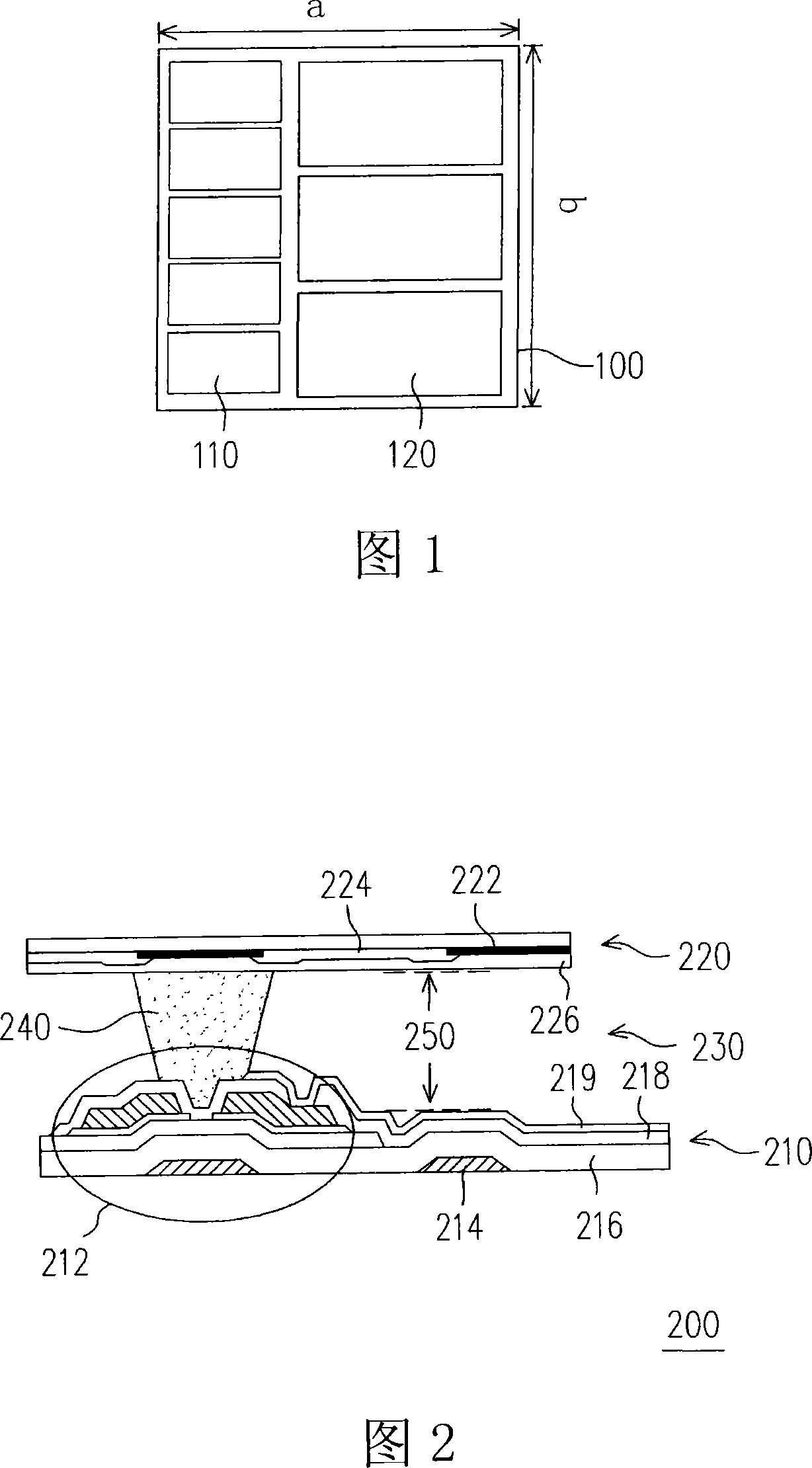

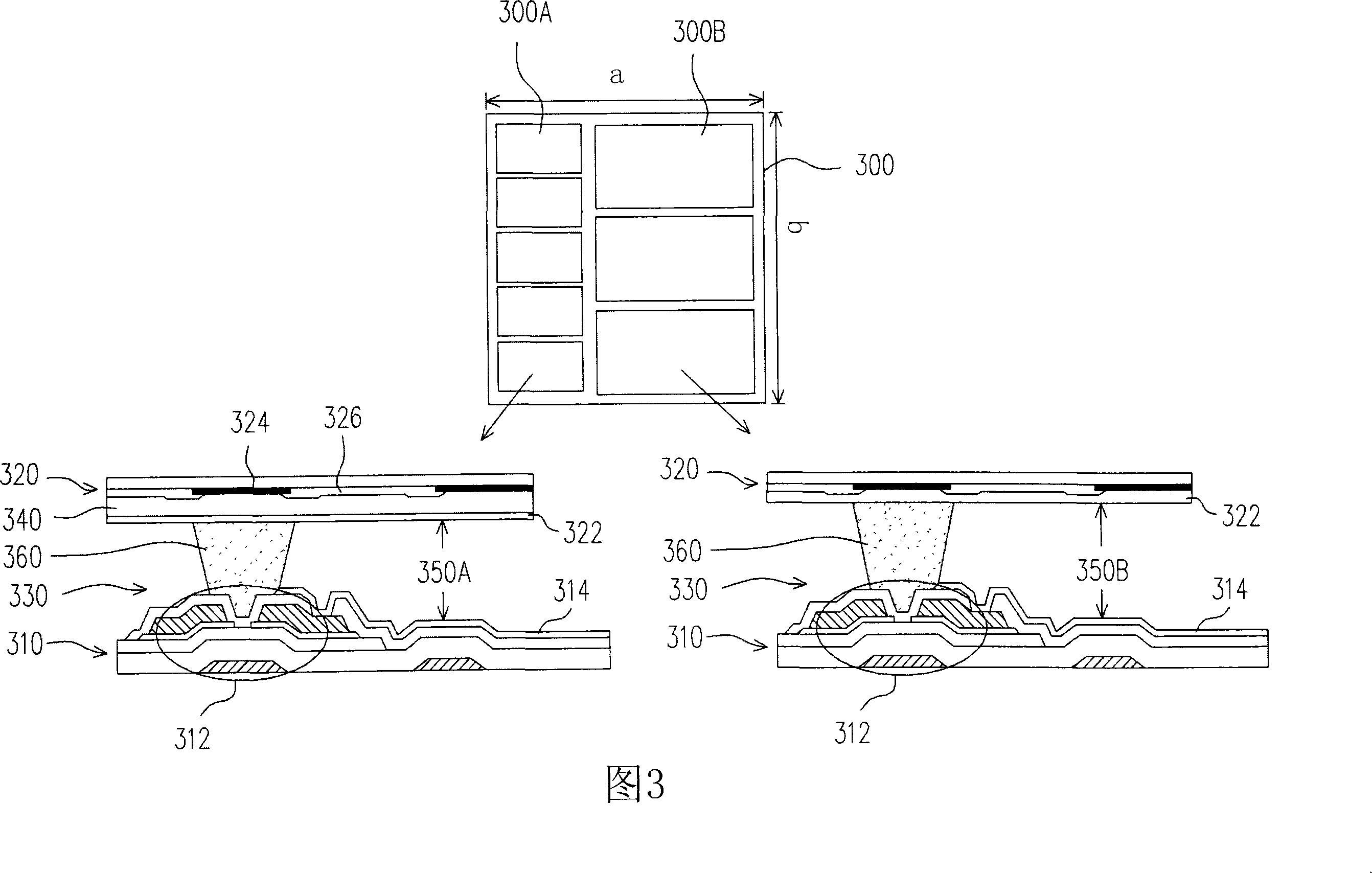

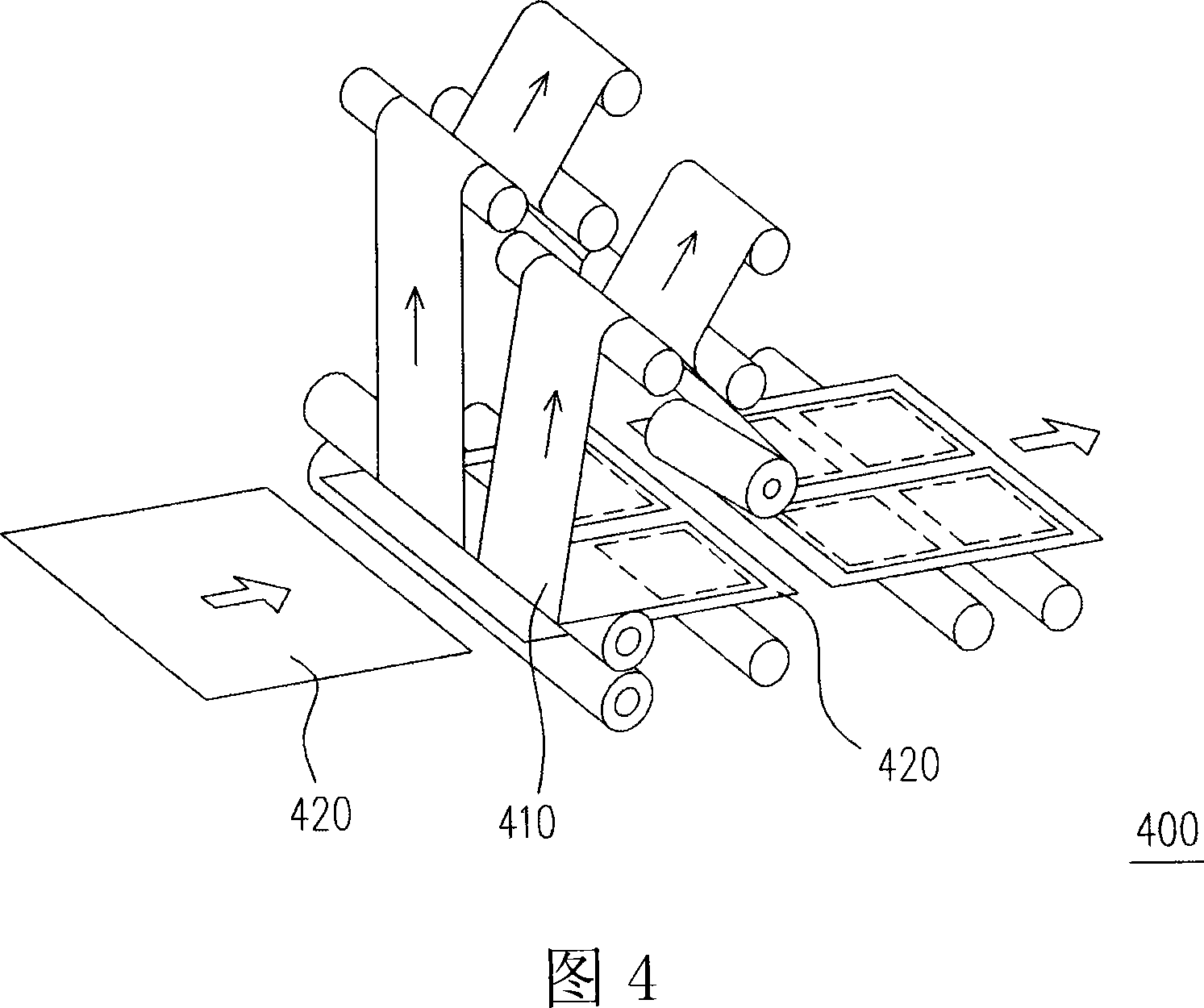

[0036] The motherboard mentioned in the following embodiments refers to the assembly of a whole piece of switching element array substrate and a whole piece of counter substrate, and sealing the display medium layer between them, forming a plurality of panels Finished unit. Cutting the motherboard can form multiple independent display panels.

[0037] These embodiments do not limit the type of the display panel, and the display panel has different action mechanisms with different display medium layers. For example, the display medium layer can be a liquid crystal material, and the display panel is called a liquid crystal display panel, such as: a transmissive display panel, a semi-transmissive display panel, a reflective display panel, a COA display panel, an AOC display panel, a vertical Alignment (VA) Display Panel, Horizontal Switching (IPS) Display Panel, Multi-Domain Vertical Alignment (MVA) Display Panel, Twisted Nematic (TN) Display Panel, Super Twisted Nematic (STN) D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com