Straw gasifying stove

A gasifier and straw technology, which is used in household stoves/stoves, lighting and heating equipment, solid heating fuels, etc., can solve problems such as pollution, straw waste, energy shortage, etc., to alleviate supply shortage, efficient combustion, and living environment improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

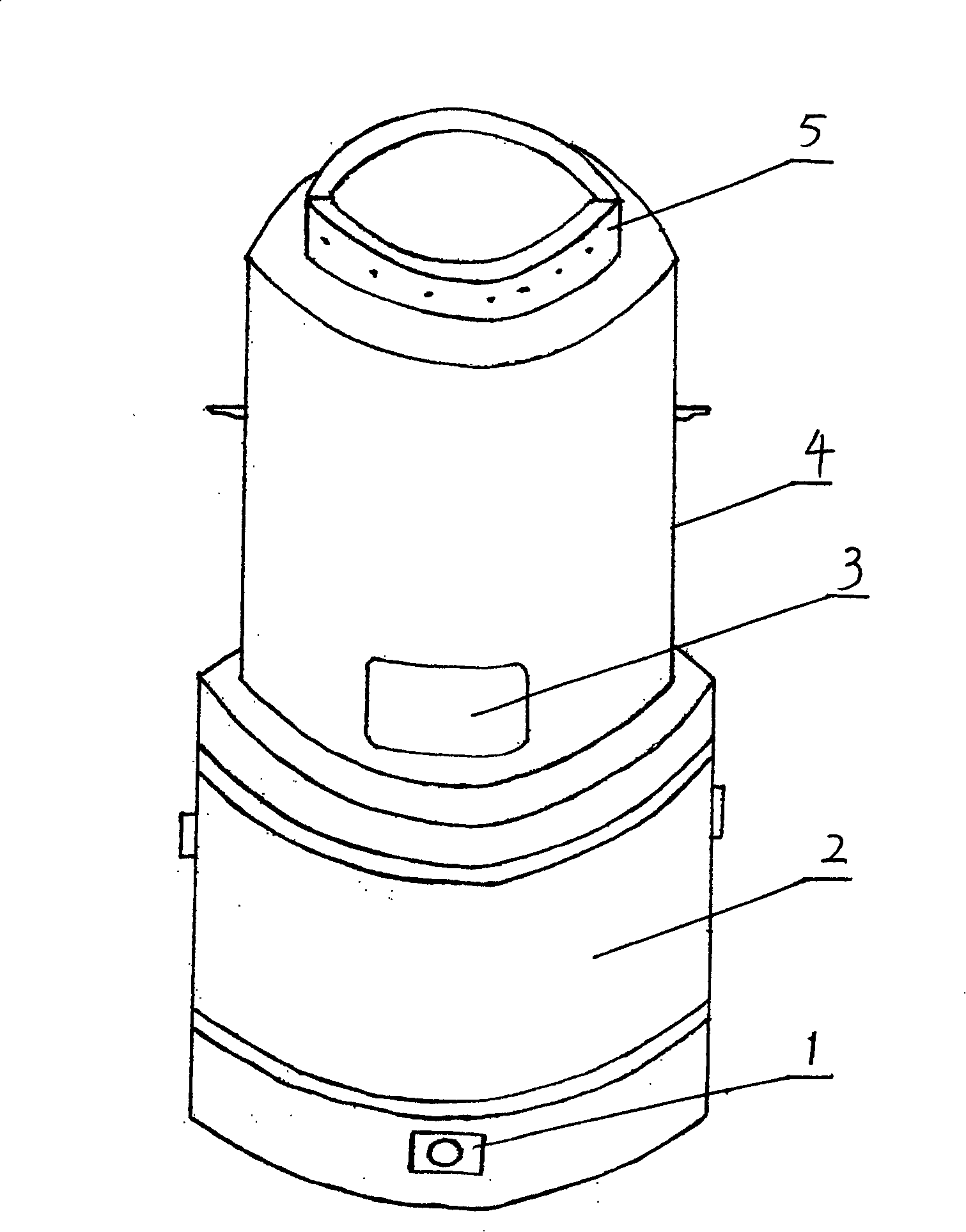

[0015] like Figure 1-4 Shown, the present invention mainly is made of barrel 2, support 4, the burner 12 that is installed in the support 4 and surrounding fire ring 5 four parts. Among them, the barrel 2, the support 4 and the fire ring 5 are detachably connected.

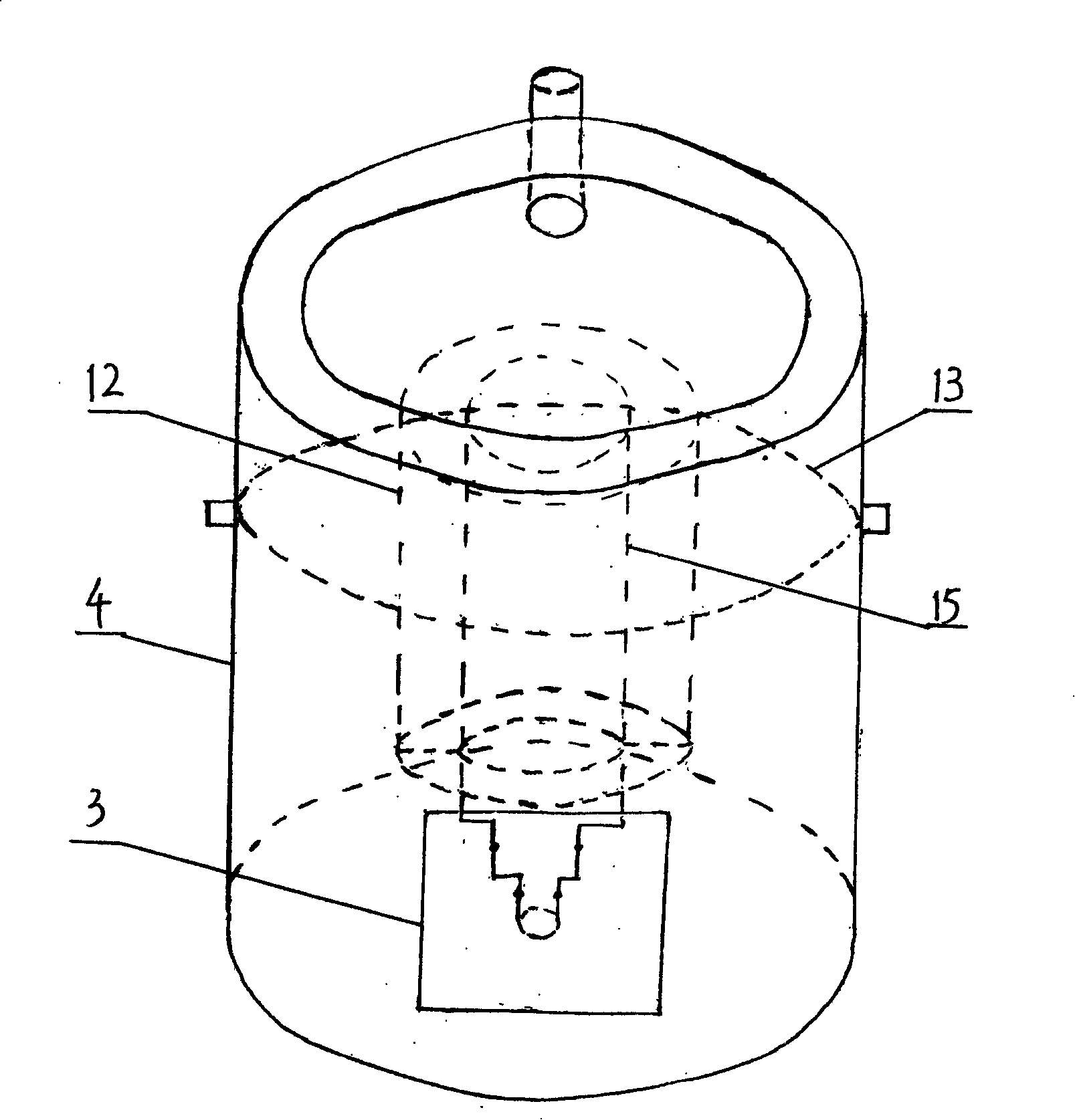

[0016] like figure 2 As shown, the bottom of the barrel 2 is provided with an ignition hole 1 connected to the ignition tube 7 , several auxiliary dampers 6 , clips 9 and a detachable movable bottom plate 8 with an air hole 19 in the center. The effect of clip 9 is that movable bottom plate 8 is stuck on barrel 2 bottoms.

[0017] The inside of the material cylinder 2 is surrounded by the porous screen cylinder 10 and the inner surface of the material cylinder 2 to form an annular space, so that the air enters the space from the auxiliary damper 6 and then enters the internal combustion chamber through the small holes on the screen cylinder to provide the oxygen required for combustion. The air outlet 11 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com