Photon crystal optical fibre coupling method and its coupling apparatus

A photonic crystal fiber and coupling device technology, which is applied in the coupling of optical waveguides, cladding fibers, optical waveguides and light guides, etc., can solve problems such as affecting the quality of optical fiber connections, and achieve easy mass production and application, high coupling efficiency, and high strength. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

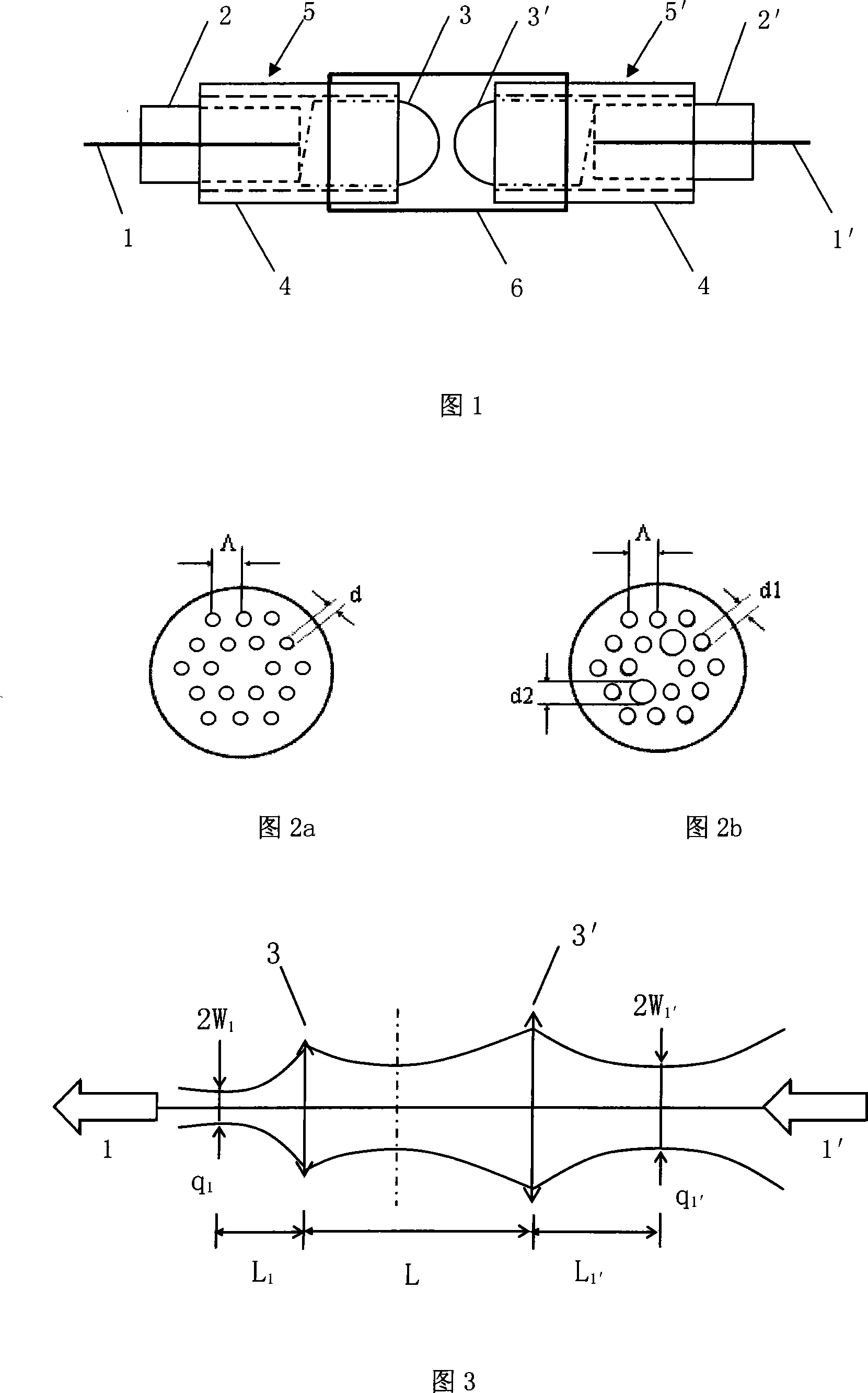

[0035] The photonic crystal fiber coupling method and its coupling device of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] The manufacturing method of the coupling device of making photonic crystal fiber described in claim 1, is characterized in that, comprises the following steps:

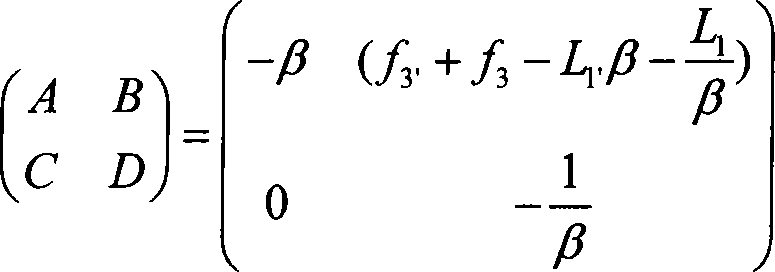

[0037]The first step is to determine the equivalent mode field radius with reference to the specific parameters of the photonic crystal fiber to be connected:

[0038] The specific parameters of the photonic crystal fiber can be obtained by the specific measurement of the fiber to be connected, which can be directly provided by the manufacturer in most cases. For example, Corning company gives an empirical formula about the equivalent core radius and hole spacing: equivalent core radius = hole spacing / 1.732, then we can measure the specific mode field radius, or according to the equivalent mode field The theoretic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com