Diesel engine fuel injector mounting structure

A technology for mounting structures and fuel injectors, applied to machines/engines, fuel injection devices, charging systems, etc., can solve the problems of increasing manufacturing costs, increasing the number of parts, increasing the number of high-pressure sealing surfaces, and achieving a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

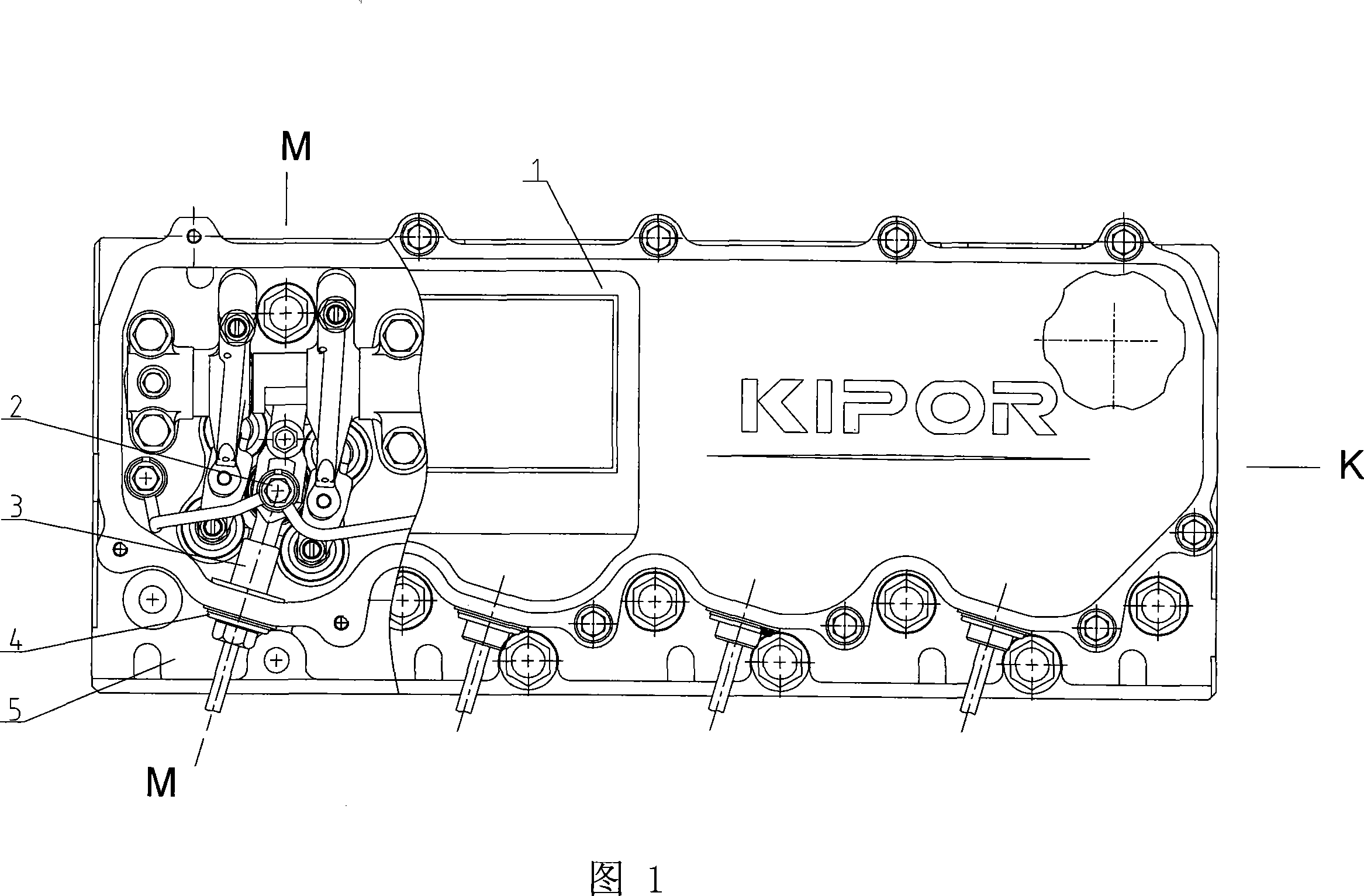

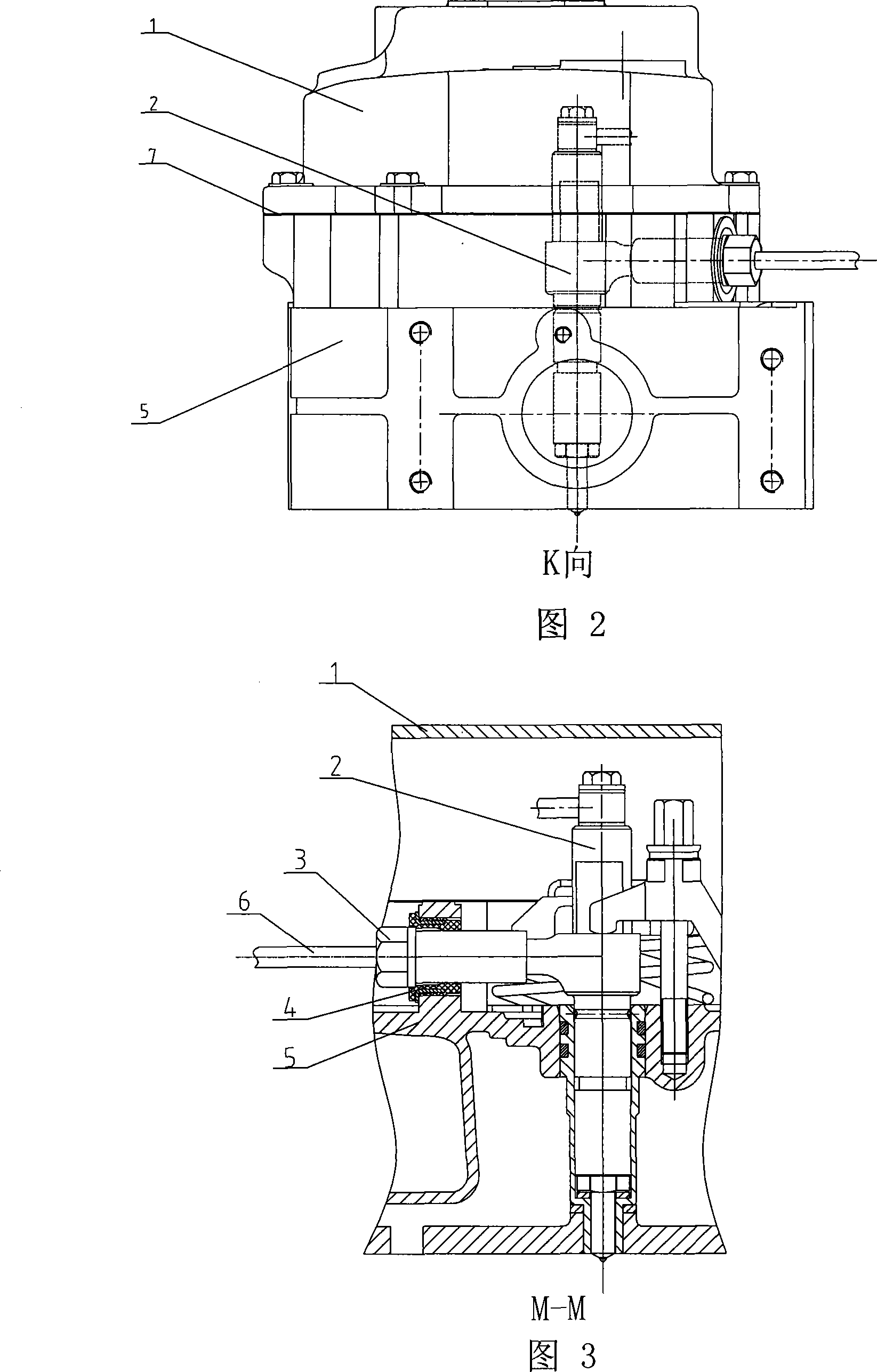

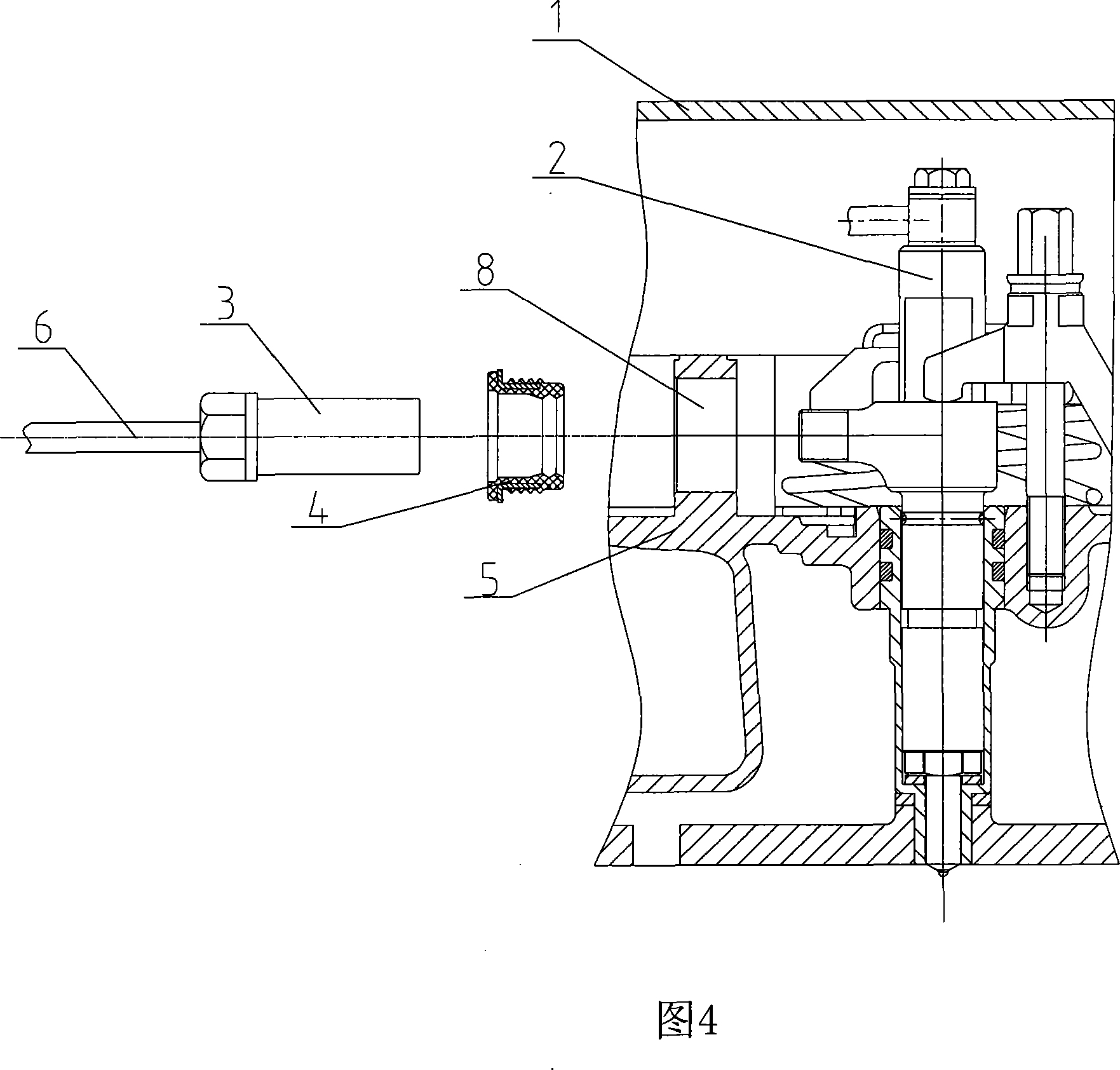

[0014] The present invention is mainly made up of cylinder head cover 1, fuel injector 2, high-pressure oil pipe joint 3, seal 4, cylinder head 5, high-pressure oil pipe 6 and sealing ring 7, and cylinder head 5 is provided with high-pressure oil pipe hole 8.

[0015] The cylinder head 5 of the present invention, the cylinder head cover 1 and the sealing ring 7 placed between the cylinder head 5 and the cylinder head cover 1 are fixed to the cylinder head 5 by bolts to form a sealed valve control chamber. A fuel injector 2 is installed in the middle of the four valves (two exhaust valves and two intake valves), and the fuel injector 2 is placed in a sealed valve control chamber. A high-pressure fuel pipe hole 8 is provided on the cylinder head 5 corresponding to the oil inlet of the fuel injector 2, and a seal 4 is installed at the high-pressure fuel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com