Bidirectional mine transport vehicle

A technology for transport vehicles and mines, which is applied in the field of transport vehicles and two-way mine transport vehicles. It can solve the problems of transportation links, multiple times of reloading, many operation links, and complex systems, and achieve low cost of motorized transportation, small turning radius, and high transportation capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

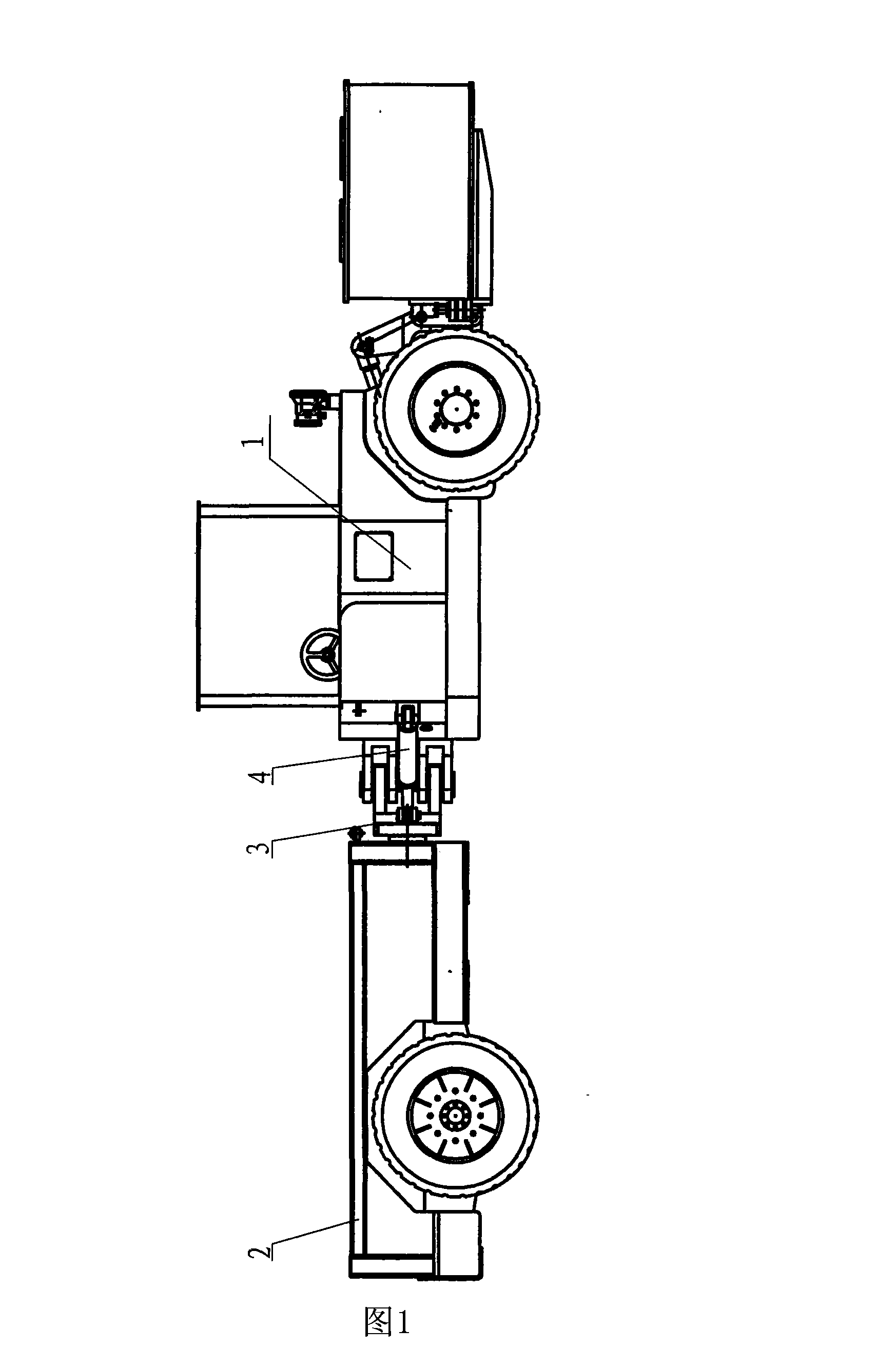

[0010] The accompanying drawing is an embodiment of the present invention, which is described in detail in conjunction with the accompanying drawings. It includes a powered locomotive 1, a trailer 2, a connecting piece 3 and an oil cylinder 4, and the trailer 2 is set as a bridgeless wheel hydraulic braking type. 1 and the center line of the towing bucket 2 and between them is provided with a connecting piece 3, one end of the connecting piece 3 is set to be hinged with the power locomotive 1 and the other end is set to be hinged with the towing bucket 2, and one end of the oil cylinder 4 is on the side of the towing bucket 2 The center line is set to be hinged with the trailer 2, and the other end of the oil cylinder 4 is set to be hinged with the power locomotive 1 at an angle of 50° with the center line of the power locomotive 1, and the oil cylinder 4 is connected to the steering gear of the power locomotive 1. In this embodiment, the powered locomotive 1 is configured as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com