Engine intake manifold

An intake manifold and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of uneven air intake and complex structure of the engine, and achieve compact layout, simple structural design, and uniform air intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

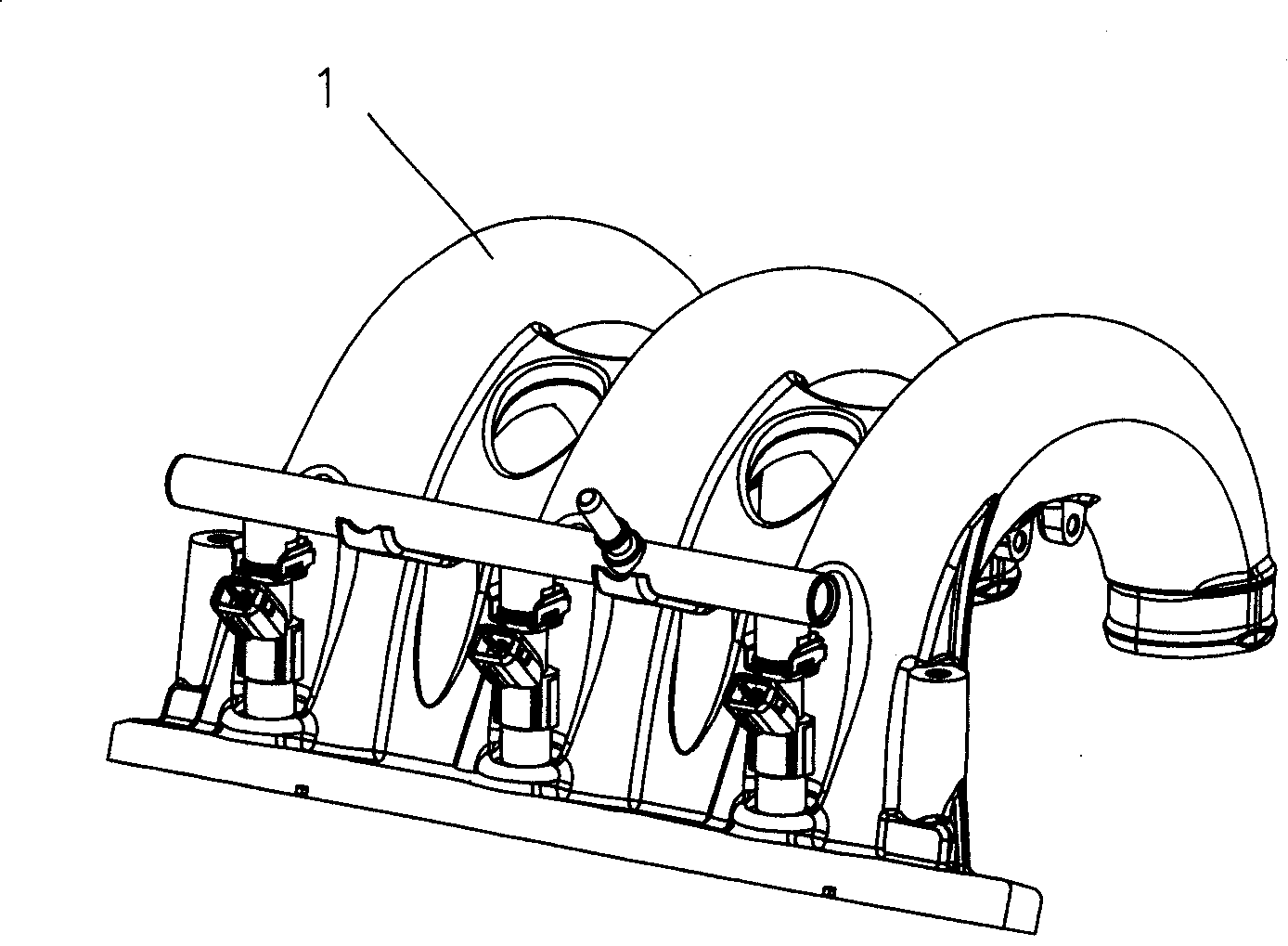

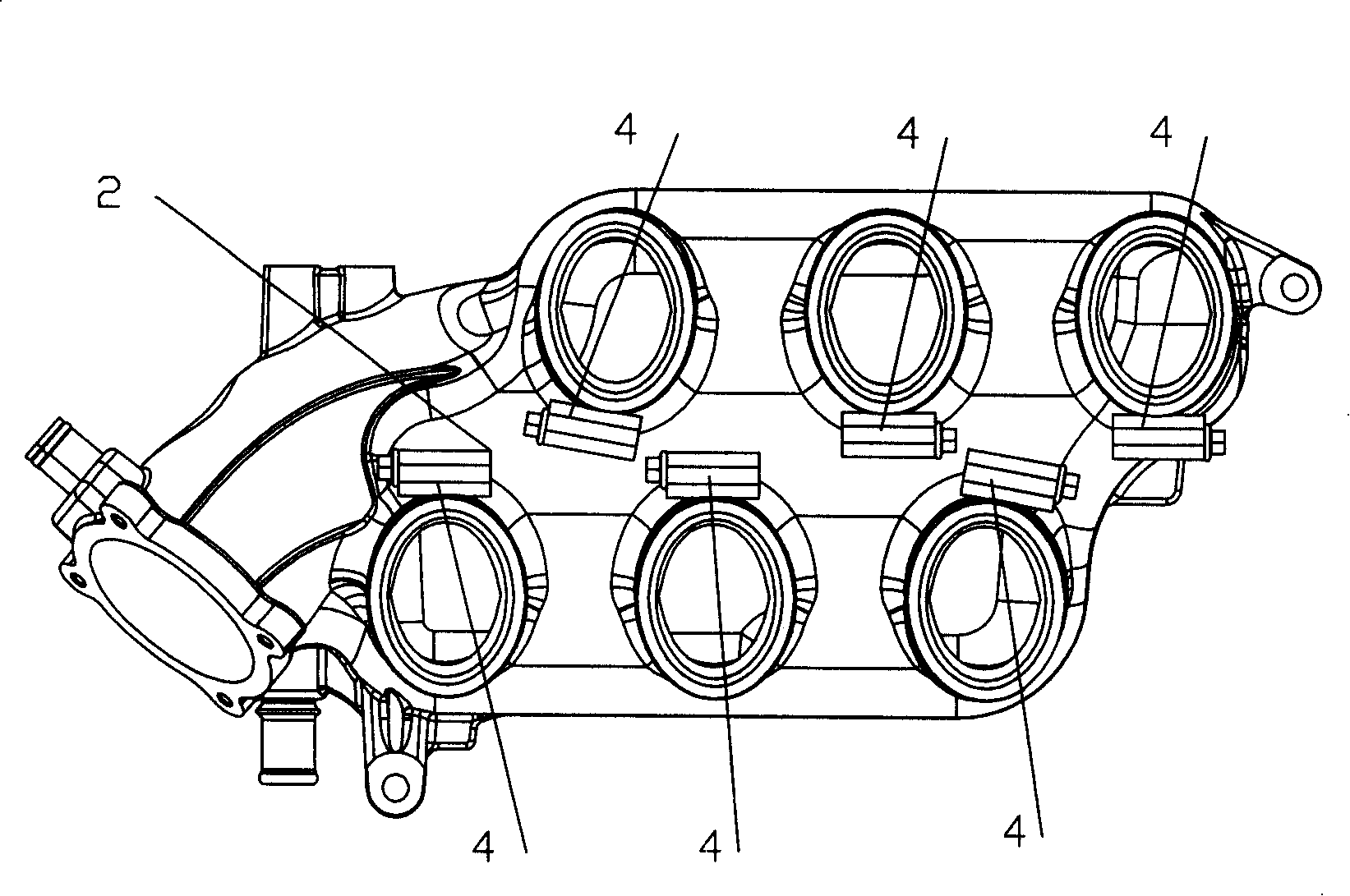

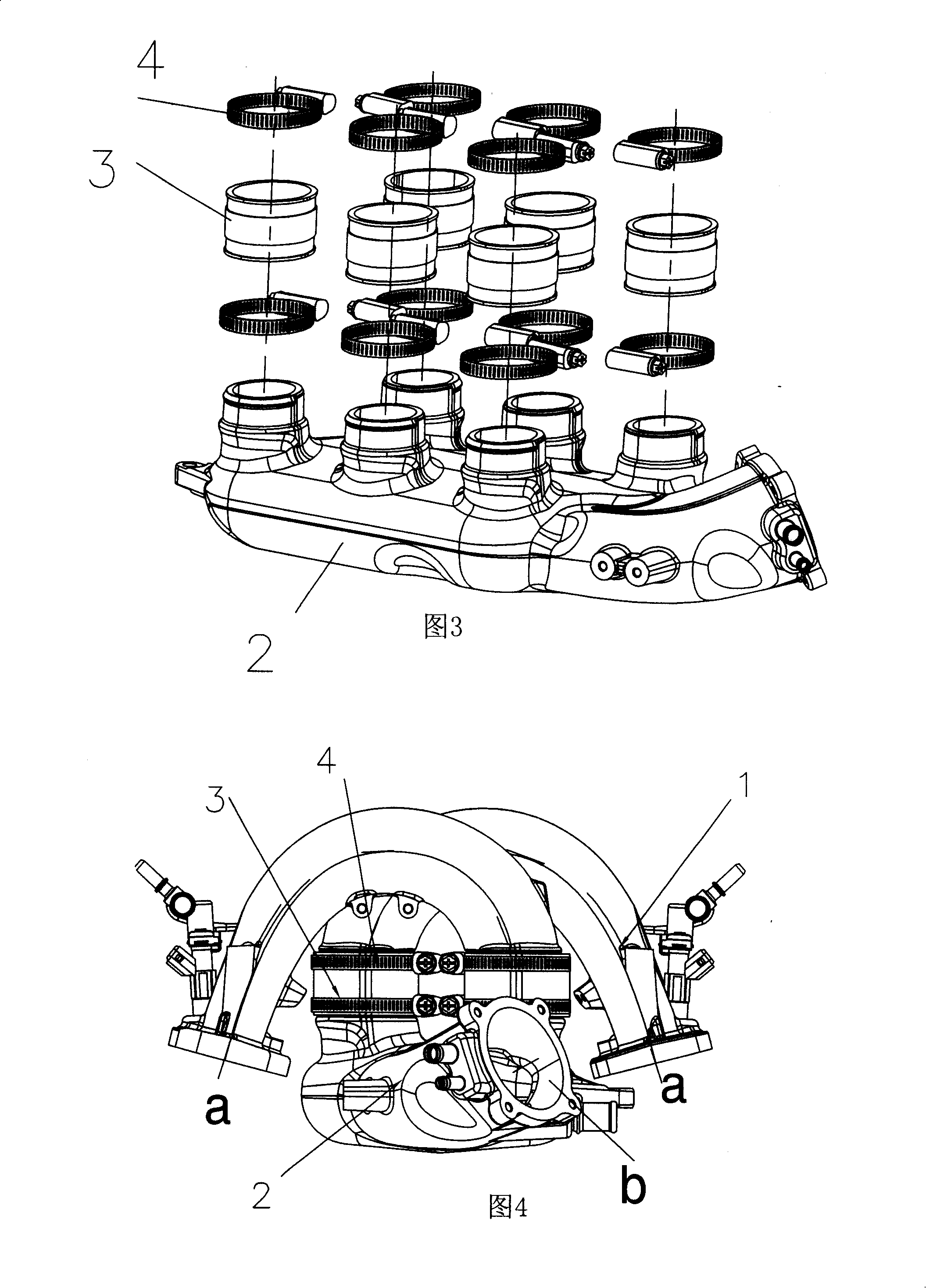

[0014] exist figure 1 , 2 , 3, 4, an engine intake manifold, the intake manifold is arranged and connected between the two cylinder heads of the V-type engine, the lower body 2 of the intake manifold is designed as a pressure-stabilizing chamber, and the pressure-stabilizing chamber has an inlet Air port, the upper body 1 of the two intake manifolds intersects, and is connected with the lower body 2 of the intake manifold through the connecting hose 3 and clamp 4 .

[0015] Such as figure 1 As shown, the upper body structure of the intake manifold is designed as a flange surface connected to the cylinder head. Three branch pipes come out from the flange surface. The air passages of the branch pipes are parallel and of the same length. The structure of the entire intake manifold is simple and easy to cast.

[0016] Such as figure 2 As shown, the structure of the lower body of the intake manifold is designed as a pressure-stabilizing chamber, and there are 6 connection outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com