Separating mechanism for paper

A separation mechanism and paper technology, applied in pile separation, object separation, object supply, etc., can solve problems such as paper jams, and achieve the effect of improving the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] First, Example 1 will be described.

[0043] FIG. 1 is a side explanatory view showing the configuration of a sheet separation mechanism in Embodiment 1. FIG.

[0044] In FIG. 1, 1 is a paper separation mechanism, which is incorporated in cash automatic teller machines, automatic ticket issuing machines, etc., and is used to separate paper such as banknotes, currency notes, and tickets stored in the storage unit. They are separated and exported one by one, and sent to the inside of a cash automatic teller machine or the like (hereinafter referred to as "inside the machine").

[0045] Reference numeral 2 denotes a pressing plate, which is a plate-shaped member for pressing the paper sheets P stored in the paper sheet storage section. The pressing plate 2 is configured to be movable by a driving device (not shown), presses the sheets P in the sheet storage section, and abuts against a lead-out roller described later.

[0046] In addition, the paper storage unit is, for ...

Embodiment 2

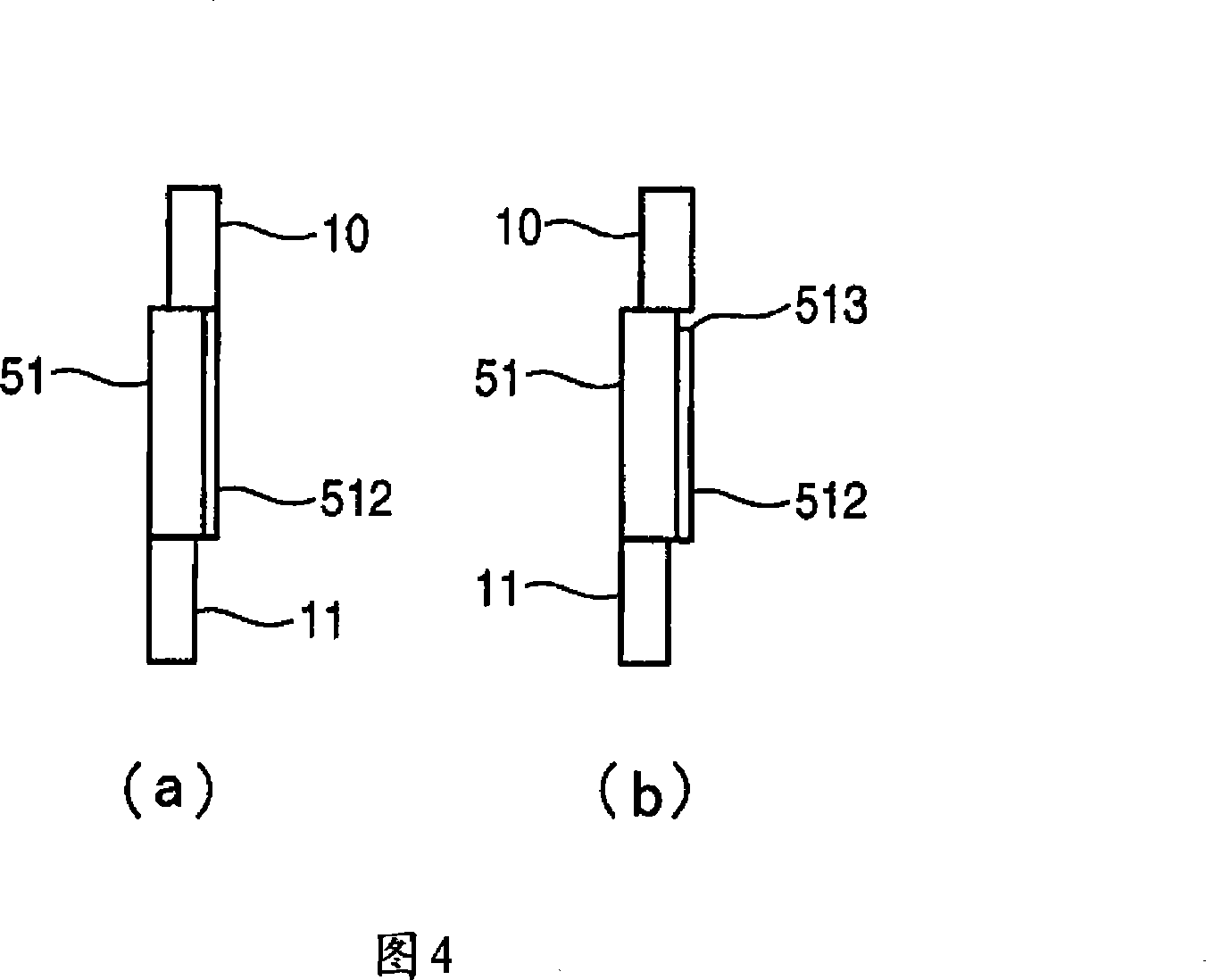

[0098] In the structure of the second embodiment, since the structure of the feed roller 5 is different from that of the first embodiment, the different structure will be described with reference to the explanatory diagram of FIG. 7 showing the structure of the feed roller in the second embodiment. .

[0099] In addition, although the structure of Example 2 is the same as that of Example 1 shown in FIG. 1, here, the transport roller hub 51 whose entire outer periphery is covered with an elastic member and has no flange will be described.

[0100] In addition, the same code|symbol is attached|subjected to the same part as the above-mentioned Example 1, and description is abbreviate|omitted.

[0101] In FIG. 7 , 70 is a feed roller rotation shaft, which is configured to be rotatable by driving means such as a motor (not shown).

[0102] 71 is a conveyance roller hub, which is attached to the feed roller rotating shaft 70, and is a roller which abuts on the 1st conveyance roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com