Gasket

A technology of gaskets and components, applied in the sealing of engines, sealing devices of engines, machines/engines, etc., can solve problems such as deterioration of sealing performance or durability, and achieve the effect of suppressing deformation and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

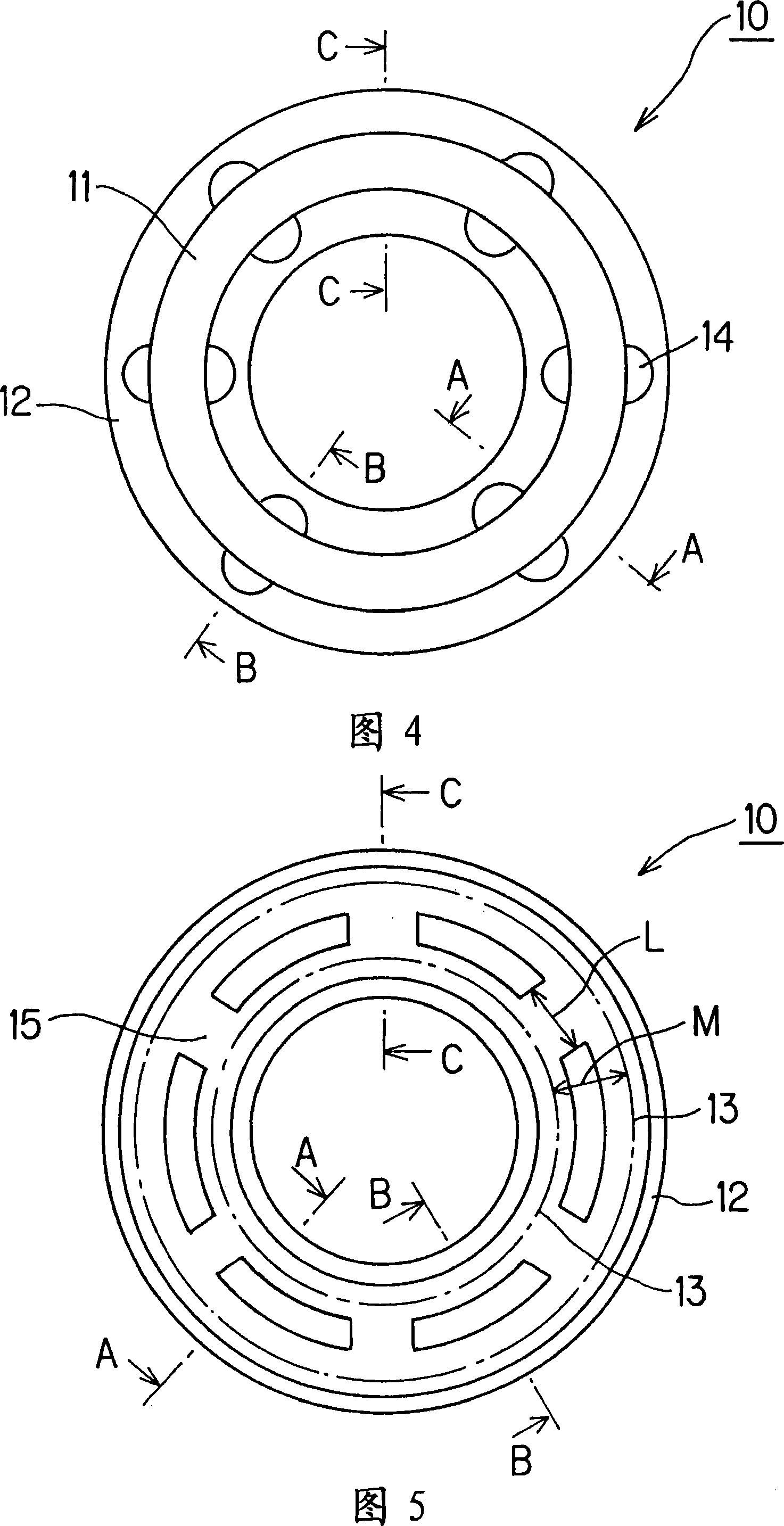

[0064] A gasket according to an embodiment of the present invention will be described in detail below with reference to FIGS. 1 to 12 .

[0065]

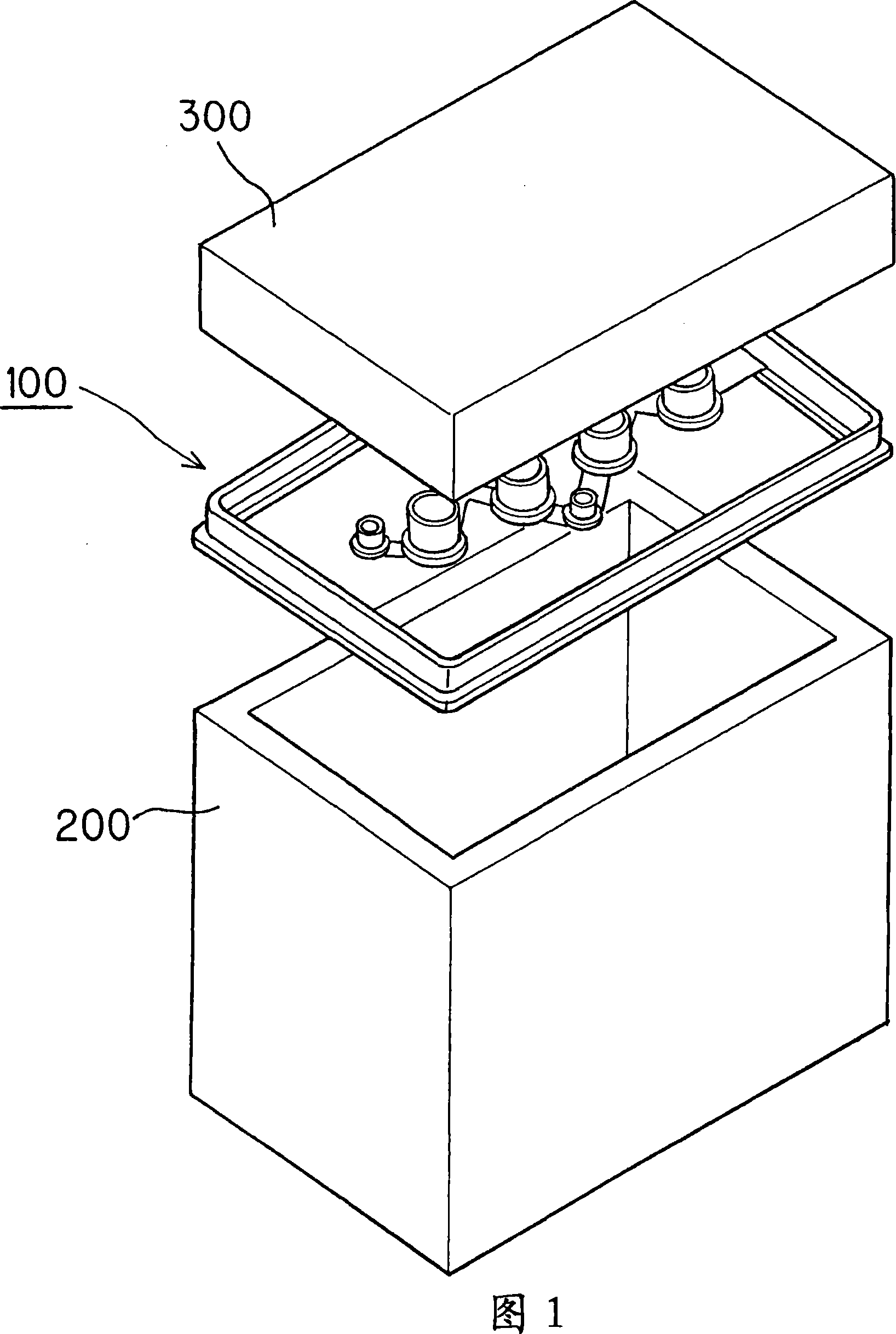

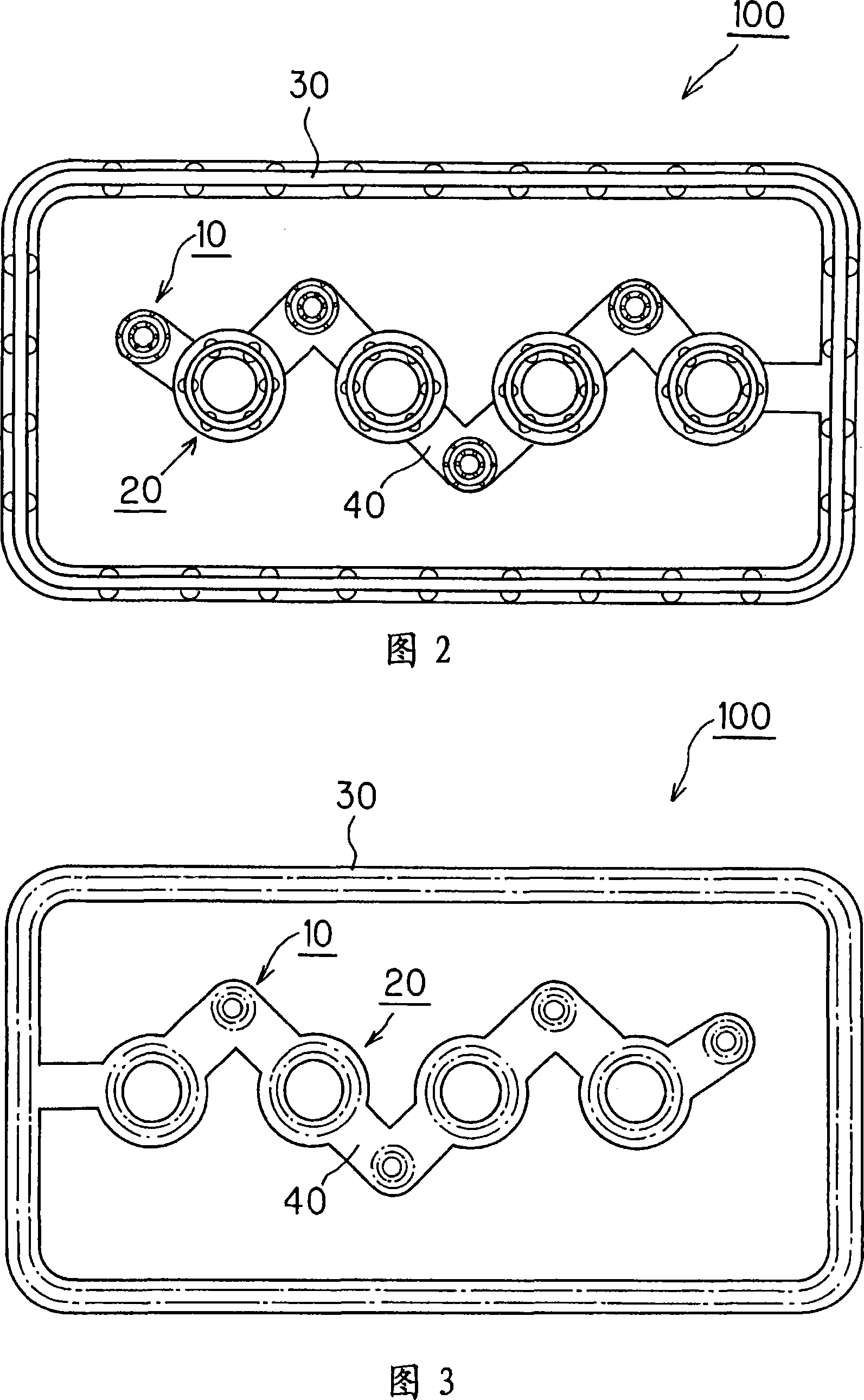

[0066] The complete gasket will be described in detail with reference to FIGS. 1 to 3 in particular. Fig. 1 is an exploded perspective view of components before a gasket is installed; Fig. 2 is a top view of a gasket according to an embodiment of the present invention; Fig. 3 is a bottom view of a gasket according to an embodiment of the present invention.

[0067]The gasket 100 of this embodiment is used to seal the gap between the cylinder head 200 and the cam cover 300 . In FIG. 1 , various components provided in the cylinder head 200 are omitted.

[0068] The gasket 100 includes a first gasket 10 for sealing the ignition coil portion, a second gasket 20 for sealing the ignition coil bolt portion, and a third gasket for sealing the outer frame portion of the cylinder head 200 and the cam cover 300 30, and a joint 40 for conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com