Engine inflow pressure-storage and control device

A control device and engine technology, applied in engine control, electrical control, machine/engine, etc., can solve the problem of inaccurate control of air intake pressure regulation and control, poor reliability and real-time performance, and inability to accurately control engine combustion And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

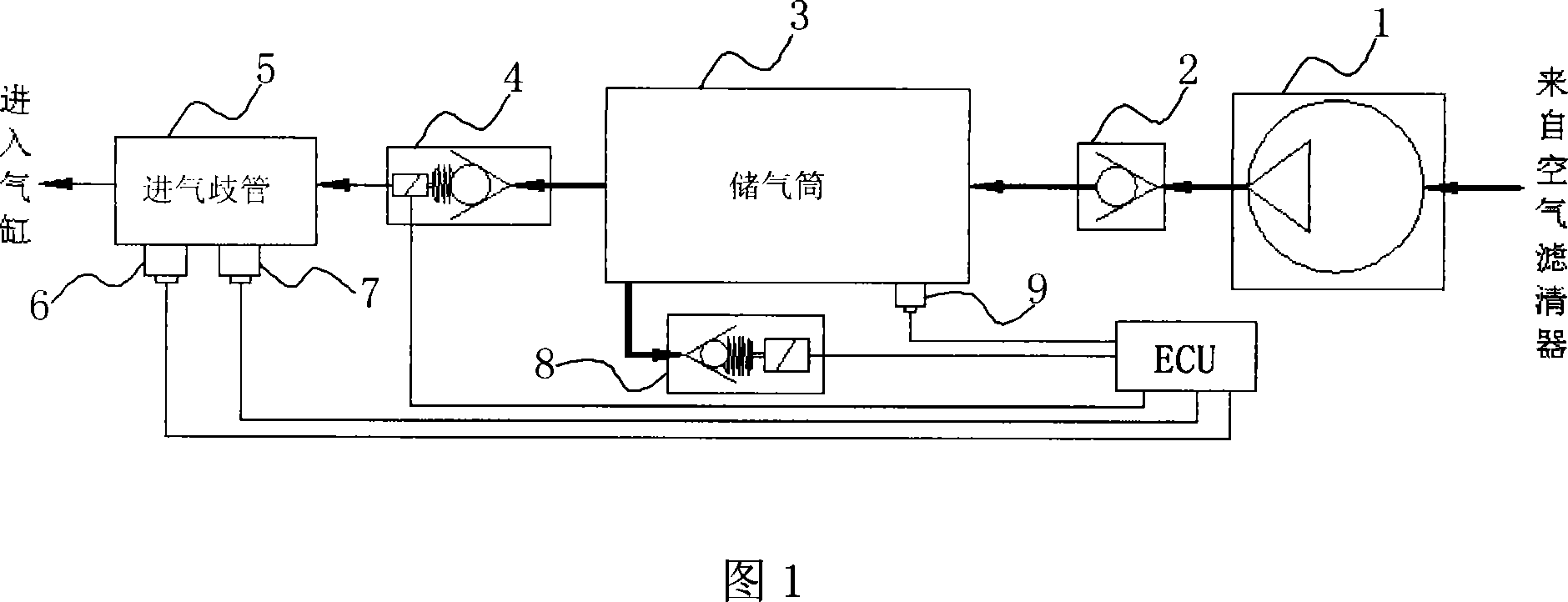

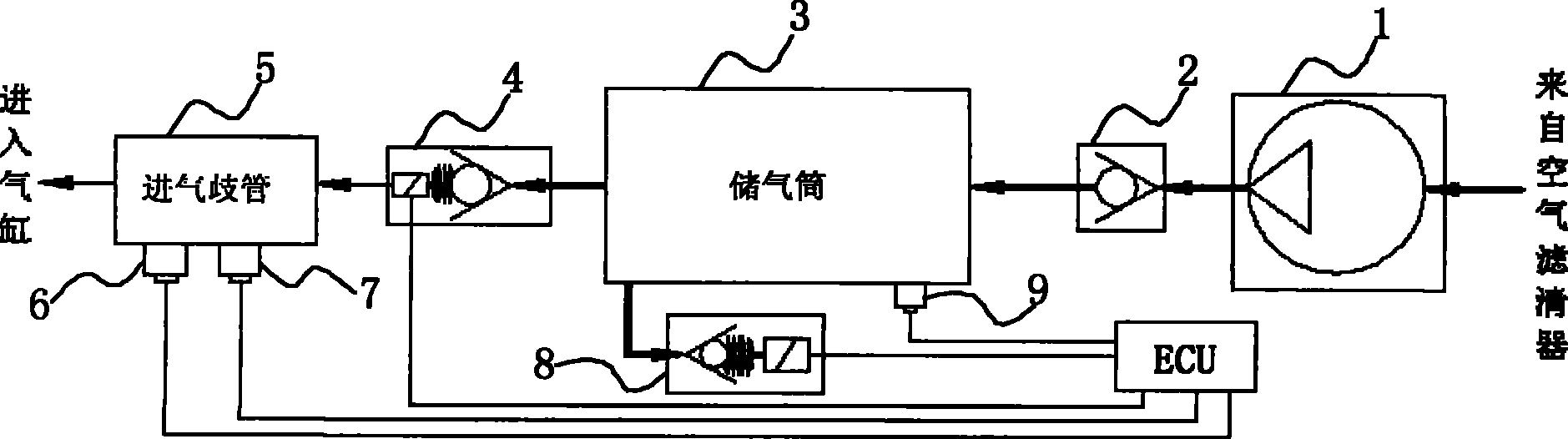

[0007] Such as figure 1 As shown, a kind of engine air intake pressure storage and control device, the inlet of the intake manifold 5 of the engine is provided with an air compressor 1, a check valve 2 and a pressure storage cylinder 3 in sequence along the air intake direction, and the pressure storage cylinder 3 and the pressure storage cylinder 3 The solenoid valve 4 controlled by the ECU is connected between the intake manifolds 5, the pressure accumulator 3 and the intake manifold 5 are respectively provided with pressure sensors 9 and 7 controlled by the ECU, and the intake manifold 5 is also provided with The intake air flowmeter 6 is controlled by the ECU, and the ECU controls the opening and closing state of the electromagnetic valve 4 through the pressure sensors 7 and 9 and the intake air flowmeter 6 .

[0008] When working normally, the solenoid valve 4 is opened, and the high-pressure gas in the pressure storage cylinder 3 enters the intake manifold 5 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com