Gap-change sensing through capacitive techniques

A capacitance change, capacitance technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, circuits, etc., can solve problems such as increased cost and increased complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

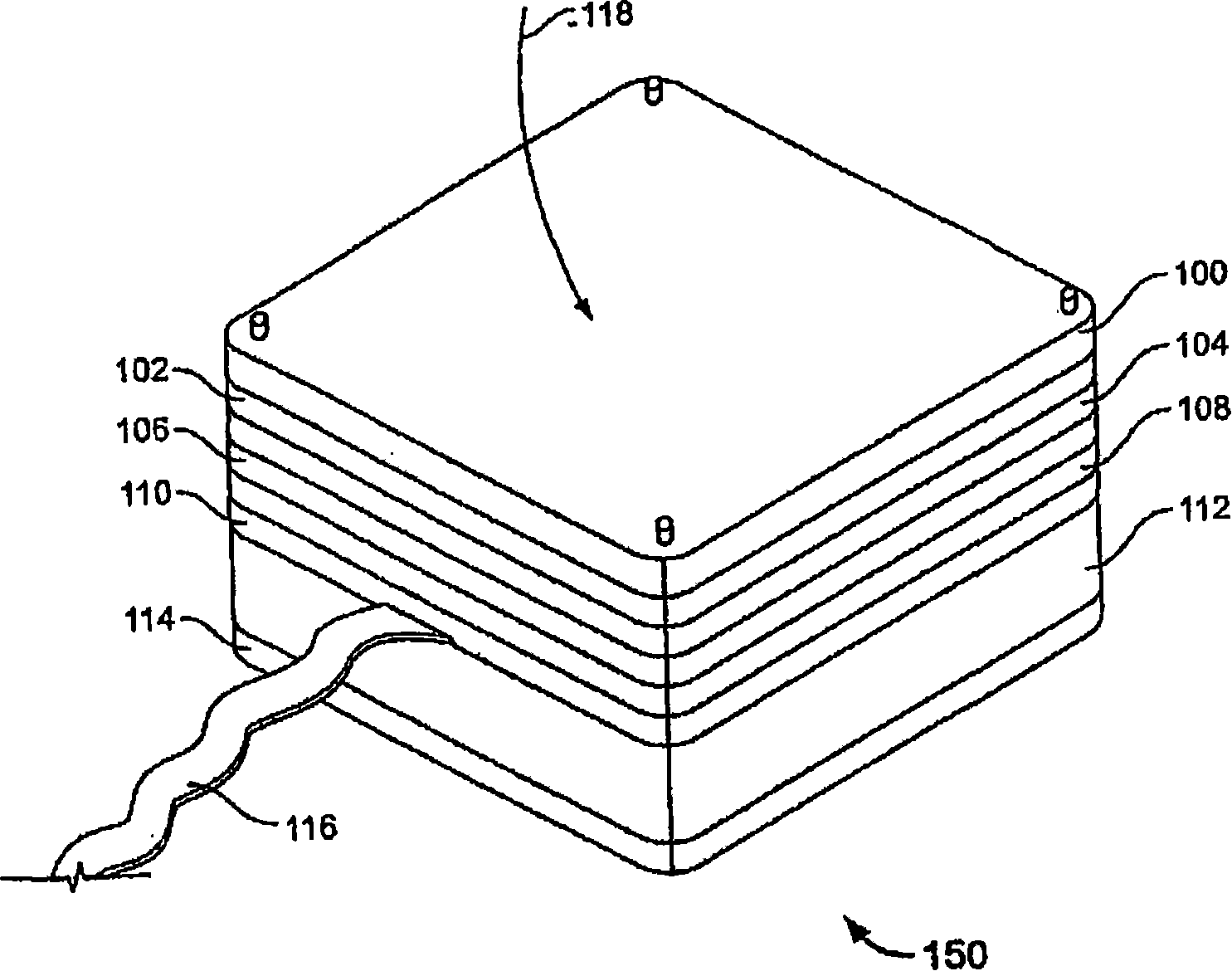

[0040] Figure 6 is according to one embodiment figure 1 A network startup diagram of device 150 is shown. In the first embodiment, the device 150A is connected via an interface cable (eg, figure 1 cable 116 and / or cable 616 of FIG. 6 ) to data processing system 602. The second device 150B is wirelessly connected to the data processing system 602 through the network 600 . In one embodiment, network 600 is the Internet. In another embodiment, the network 600 is a local area network. Data processing system 606 may receive data from device 150A and / or device 150B via network 600 (eg, output data measuring forces and / or loads, etc.). In one embodiment, data processing system 606 analyzes data (eg, measurements) generated by various operations of a device (eg, stacked device 150A). Access device 604 (eg, a device capable of wireless communication between devices forming a wireless network) may provide a wireless connection to device 150B. In one embodiment, device 150B include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com