Friction clutch

A technology of friction clutches and disc springs, applied in the direction of friction clutches, clutches, mechanically driven clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

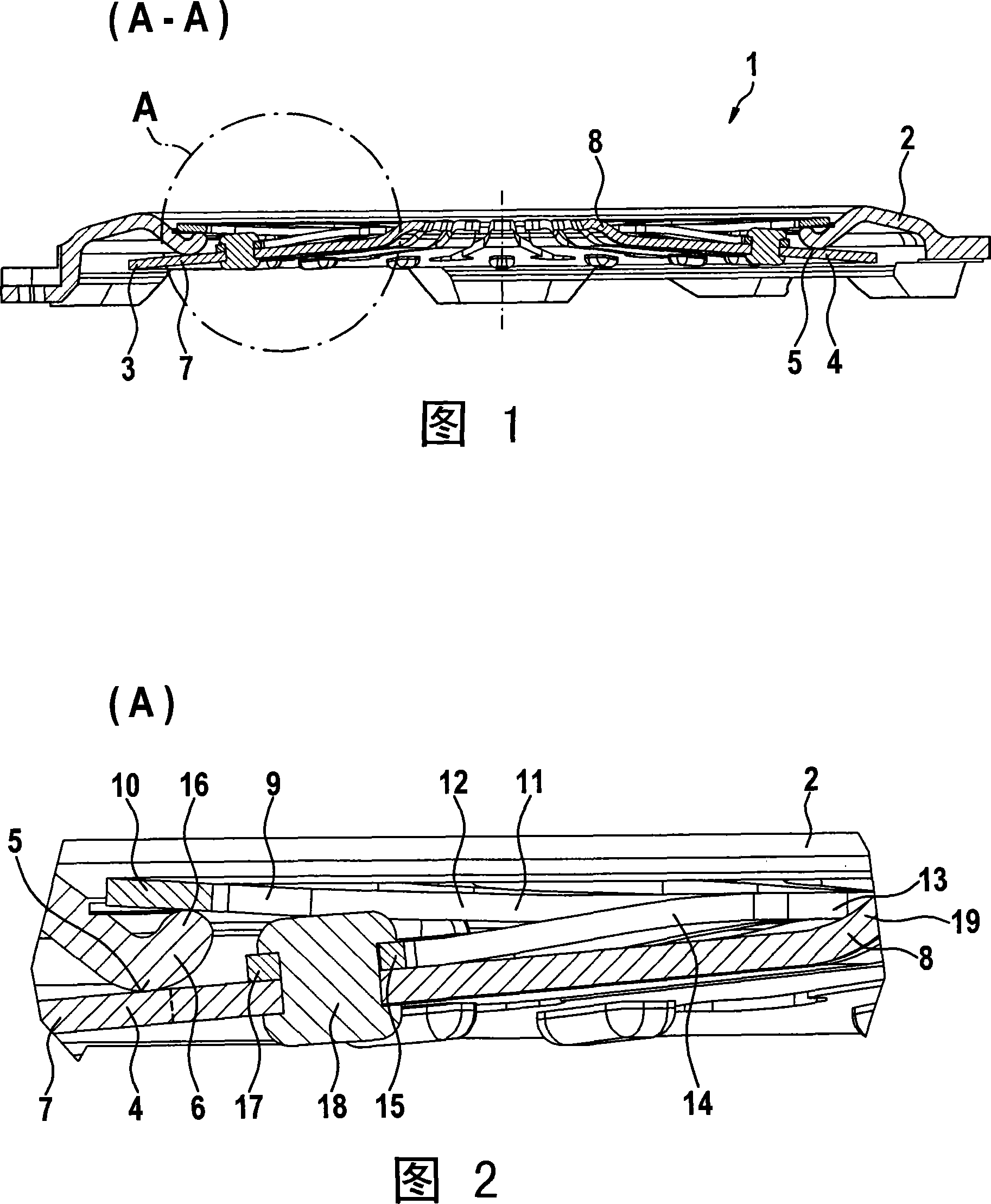

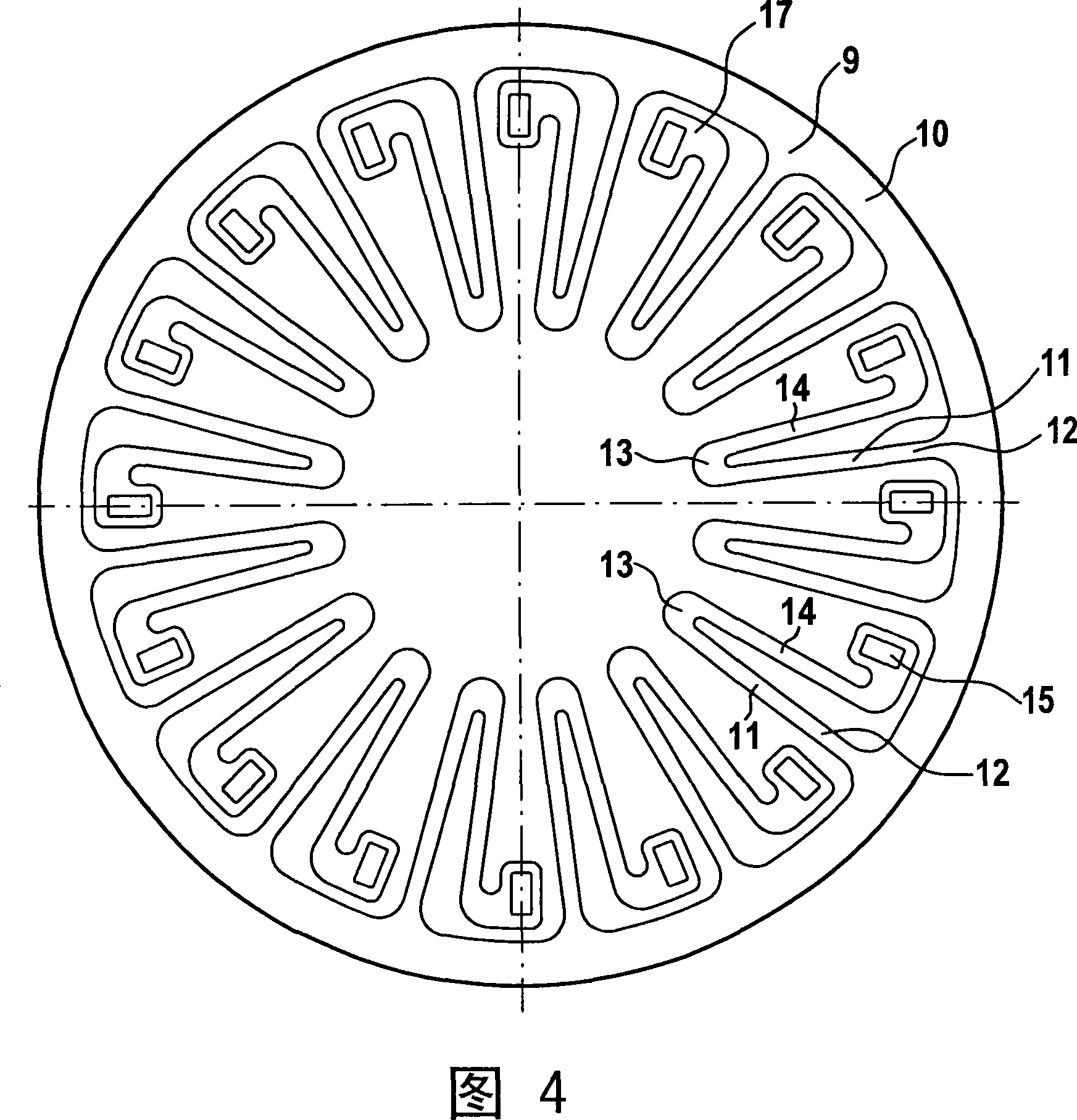

[0018] The friction clutch 1 shown in these figures has a housing 2 here made of sheet metal and a pressure plate which is non-rotatably connected to the housing but displaceable in a limited axial direction. The disc is not shown here. Axially clamped between the pressure plate and the cover 2 is a compression disc spring 4 which, as can be seen in particular from FIG. The radial height of the support region 5 pivots like a double-armed lever. The disk spring 4 acts on a pressure plate with a radially far outer region 3 . The pressure plate is non-rotatably connected to the housing 2 via leaf springs directed in the circumferential direction or tangentially. The friction clutch 1 can be mounted on a counter-pressure plate, not shown here, wherein a frictional contact between the friction surface of the counter-pressure plate and the friction surface of the pressure plate can be carried out in a known manner, precisely on the basis of tension by a disk spring 4 . The axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com