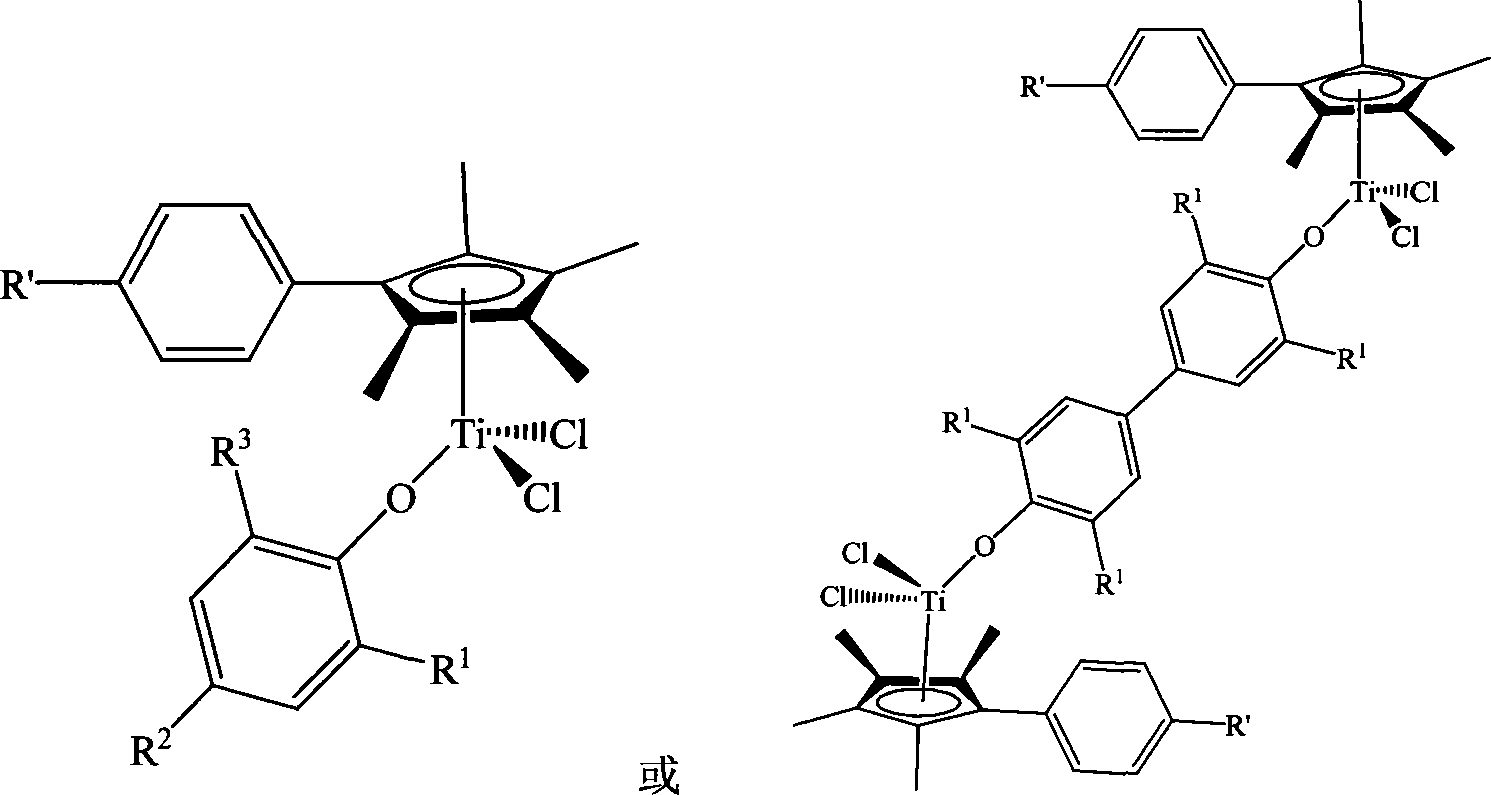

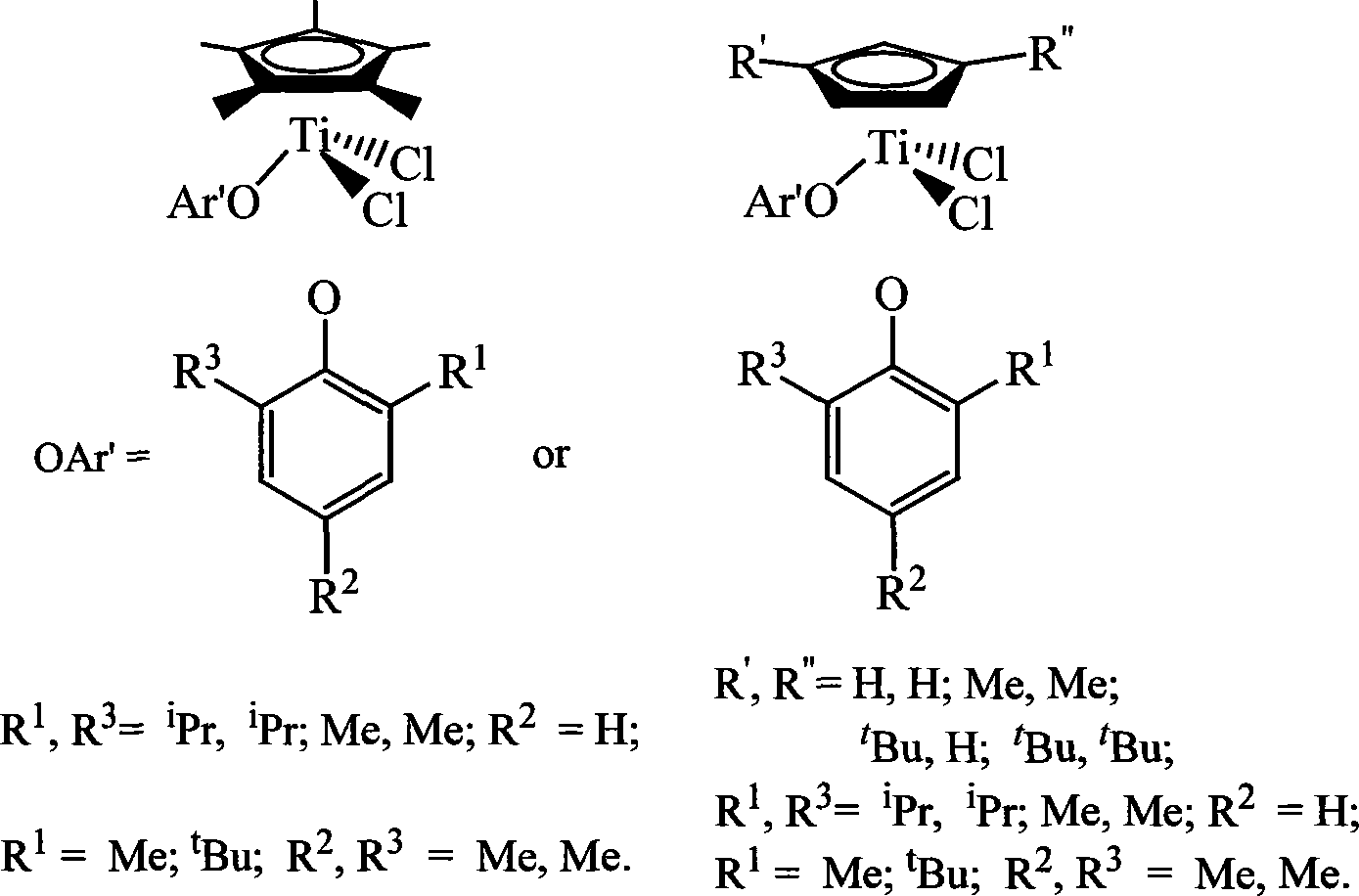

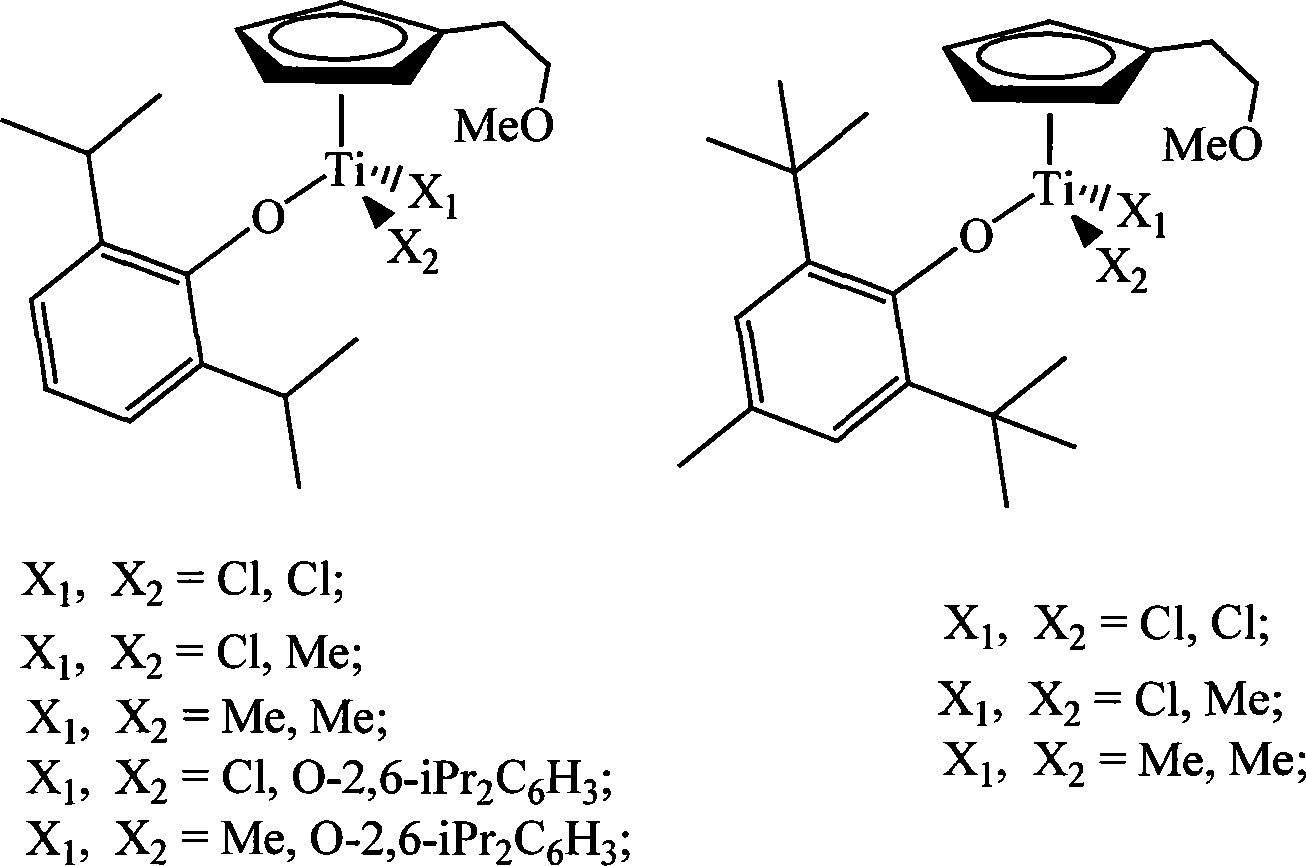

Non-bridged single/double-nucleus metallocene compound and uses thereof

A metallocene compound and bridging technology, which is applied in the field of olefin polymerization catalysts and its preparation and application, can solve the problems of unfavorable catalyst stability and reduced catalytic activity, and achieve the effect of improving the application range and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Synthesis of 1-(4-methyl)-phenyl-2,3,4,5-tetramethylcyclopentadienyl ligand The synthetic reaction equation is:

[0037]

[0038] The specific process is: in N 2 Under the atmosphere, add 15.9ml 2,3,4,5-tetramethylcyclopent-2-en-1-one (36mmol) ether solution to the reaction bottle, slowly add 18ml dropwise under ice-salt condition, 2.0 M 4-Methyl-phenyl lithium salt (4-Me-PhLi, 36 mmol) in ether. Under stirring conditions, it was gradually raised to room temperature and reacted for about 30 hours. The reaction mixture was poured into cold water, and the pH value was adjusted to about 1 with hydrochloric acid. The aqueous layer was extracted with ether, and the combined organic phase was washed with 120 ml of saturated ammonium chloride aqueous solution, and then washed with MgSO 4 dry. The desiccant was removed by filtration, the solvent was evaporated under reduced pressure, and column chromatography (developing solvent: dichloromethane / petroleum ether...

Embodiment 2

[0041] Example 2 Synthesis of 1-(4-isopropyl)-phenyl-2,3,4,5-tetramethylcyclopentadienyl ligand

[0042] Under a nitrogen atmosphere, add 15.90ml of ether solution containing 2,3,4,5-tetramethylcyclopent-2-en-1-one (36mmol) to the reaction flask, and slowly Add 20ml of a 1.8M ether solution of 4-isopropyl-phenyllithium salt (4-ipr-PhLi, 36mmol). . Under the condition of stirring, it was gradually raised to room temperature and reacted for 30 hours. The reaction mixture was poured into ice water, and the pH value was adjusted to about 1 with hydrochloric acid. The aqueous layer was extracted with ether, and the combined organic phases were washed with a saturated aqueous solution of ammonium chloride (120ml), washed with MgSO 4 dry. The desiccant was removed by filtration, the solvent was evaporated under reduced pressure, and the product was separated by column chromatography (developing solvent: dichloromethane / petroleum ether=1:3 mixed solvent) to obtain 6.66 g of the pr...

Embodiment 3

[0045] Example 3 Synthesis of 1-(4-tert-butyl)-phenyl-2,3,4,5-tetramethylcyclopentadienyl ligand

[0046] Under a nitrogen atmosphere, add 15.90ml of ether solution containing 2,3,4,5-tetramethylcyclopent-2-en-1-one (36mmol) to the reaction flask, and slowly Add 22.5 mL of a 1.6M ether solution of 4-tert-butyl-phenyllithium salt (4-tbu-PhLi, 36 mmol). . Under the condition of stirring, it was gradually raised to room temperature and reacted for 30 hours. The reaction mixture was poured into ice water, and the pH value was adjusted to about 1 with hydrochloric acid. The aqueous layer was extracted with ether, and the combined organic phases were washed with a saturated aqueous solution of ammonium chloride (120ml), washed with MgSO 4 dry. The desiccant was removed by filtration, the solvent was evaporated under reduced pressure, and the product was separated by column chromatography (developing solvent: dichloromethane / petroleum ether=1:3 mixed solvent) to obtain 7.23 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com