Laser lancet

A scalpel and laser technology, applied in the fields of biology and medicine, can solve the problems of not easy to make small size, not easy to miniaturize, and unpredictable practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

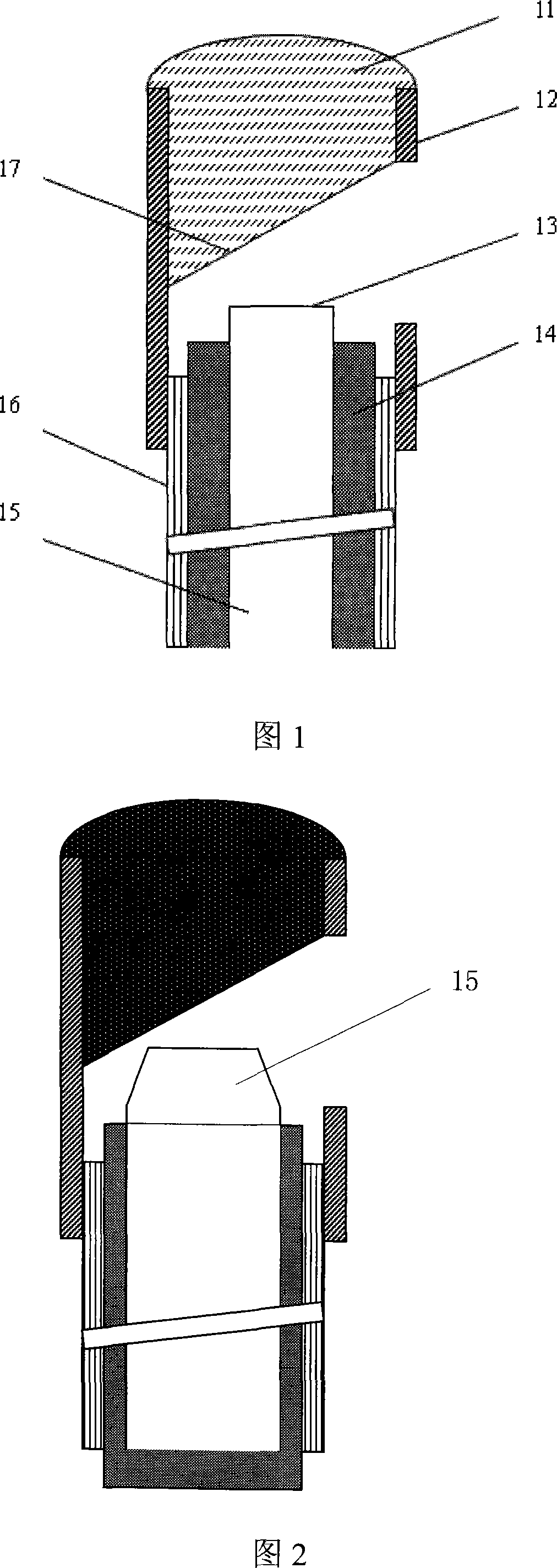

[0027] The laser scalpel of the present invention comprises a cutter head, and Fig. 1 is a cutter head optics overall structural diagram of the laser scalpel of the present invention, and this cutter head comprises a support structure 11, a cutter head main body 12, a focusing shaping device 13, and an optical cable inner layer wrapping material 14, energy transmission optical fiber 15, optical cable outer protective sheath 16 and beam emission angle control unit 17. The energy transmission optical fiber 15 includes an emitting end face. The beam emission angle control unit 17 includes an optical fiber pigtail that processes the core and cladding into a certain angle and diameter distribution along the axial direction, a pigtail emission end face and a reflective mirror, and the pigtail emission end face, reflection surface Optical or metal thin films with three-dimensional micro-nano structures are arranged on the surface of the mirror. The reflective mirror is set opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com