General purpose type wood substance grain forming technique

A wood pellet, general-purpose technology, applied in application, feed, food science, etc., can solve the problems of less pellets, high output energy consumption, inability to meet pelletizing and other problems, reduce energy consumption per unit of output, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

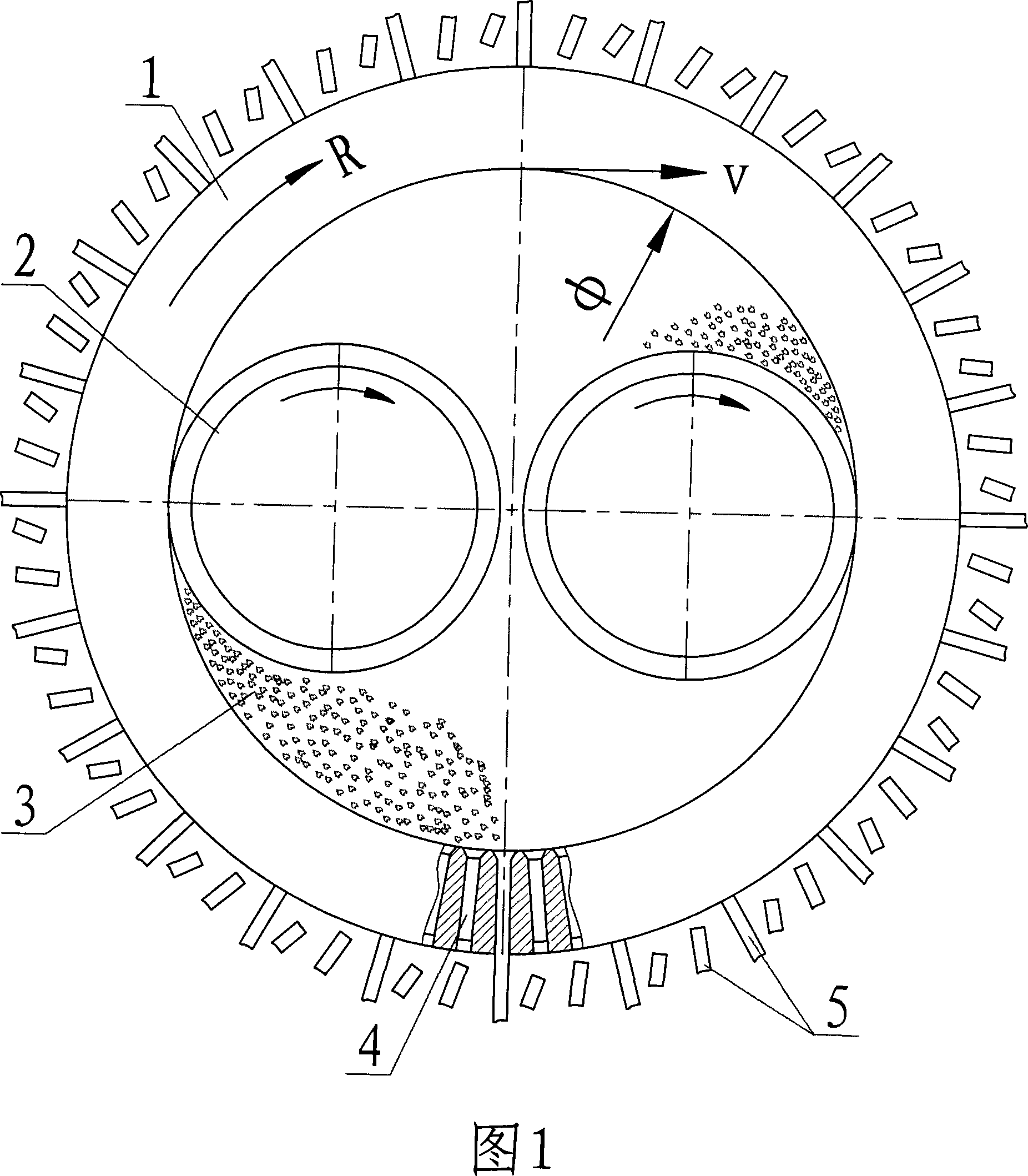

[0014] Referring to Fig. 1, the raw material 3 is miscellaneous wood mixed sawdust, which is changed from the Shende 420 ring die livestock and poultry feed pellet mill to a wood pellet pellet mill. The main motor of the original granulator is 2×55kW-4P (4 poles), the rated speed of the motor is 1450rpm, the motor drives the pressure roller 2 to rotate, the speed R of the ring die 1 is 335rpm, the inner diameter of the ring die is Φ420mm, and the line speed v of the ring die is 7.37m / s; changed to the main motor 2×55kW-6P (6 poles), the rated speed of the motor is 960rpm, the speed R of the ring die 1 is 222rpm, the inner diameter of the ring die is Φ420mm, and the line speed v of the ring die is 4.88m / s. The diameter of the die hole is 6-8mm, and the ratio of the diameter to the length of the ring die hole 4 is 1:6-1:10.

[0015] 80% of the particle size of raw material 3 is 3-4mm, and the remaining particle size is less than 1mm. The output of the granulator is 1.5-1.8t / h, a...

Embodiment 2

[0017] Referring to Fig. 1, raw material 3 is sawdust, which is changed from Shende 520 ring die livestock and poultry feed granulator to wood pellet granulator. The main motor of the original granulator is 2×75kW-4P (4 poles), the rated speed of the motor is 1450rpm, the transmission ratio is 1:4.33, the speed R of the ring die is 335rpm, the inner diameter of the ring die is Φ520mm, and the line speed v of the ring die is 9.12m / s; change the main motor to 2×75kW-6P (6 poles), the rated speed of the motor is 960rpm, the transmission ratio is increased to 1:8.22, the speed R of the ring die is 176rpm, the inner diameter of the ring die is Φ520mm, and the line speed v of the ring die is 4.8 m / s, the diameter of the ring die hole is 6-8mm, and the ratio of the diameter to the length of the ring die hole 4 is 1:5-1:9.

[0018] The particle size of 80% of the raw materials is 3-4mm, and the remaining particle size is less than 1mm. The output of the granulator is 2.0-2.5t / h, and ...

Embodiment 3

[0020] Referring to Fig. 1, raw material 3 is sylvestris sylvestris shavings, which is changed from Zhengchang 300 ring die livestock and poultry feed granulator to wood pellet granulator. The main motor of the original granulator is 30kW-4P (4 poles), the rated speed of the motor is 1450rpm, the motor drives the pressure roller 2 to rotate, the speed R of the ring die is 378rpm, the inner diameter of the ring die is Φ300mm, and the line speed v of the ring die is 6.08m / s ;The main motor is still 30kW-4P (4 poles), increase the frequency converter, adjust the motor speed from the rated speed to 725~1015rpm (frequency conversion frequency 25~35Hz), the ring die speed R is 189~265rpm, the inner diameter of the ring die Φ300mm, the ring die line speed v is 3.04-4.26m / s, the ring die aperture is 6-8mm, and the diameter-to-length ratio of the ring die hole 4 is 1:6-1:10.

[0021] The particle size of 80% of the raw materials is 3-4mm, and the remaining particle size is less than 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com