Two-piece side and floor panel arrangement for box assembly

A technology for carriages and floors, applied to the upper structure of trucks, vehicle components, upper structures, etc., can solve complex and expensive processing tools and other problems, and achieve the reduction of material consumption and cost, simplification of assembly operations, and reduction of total weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

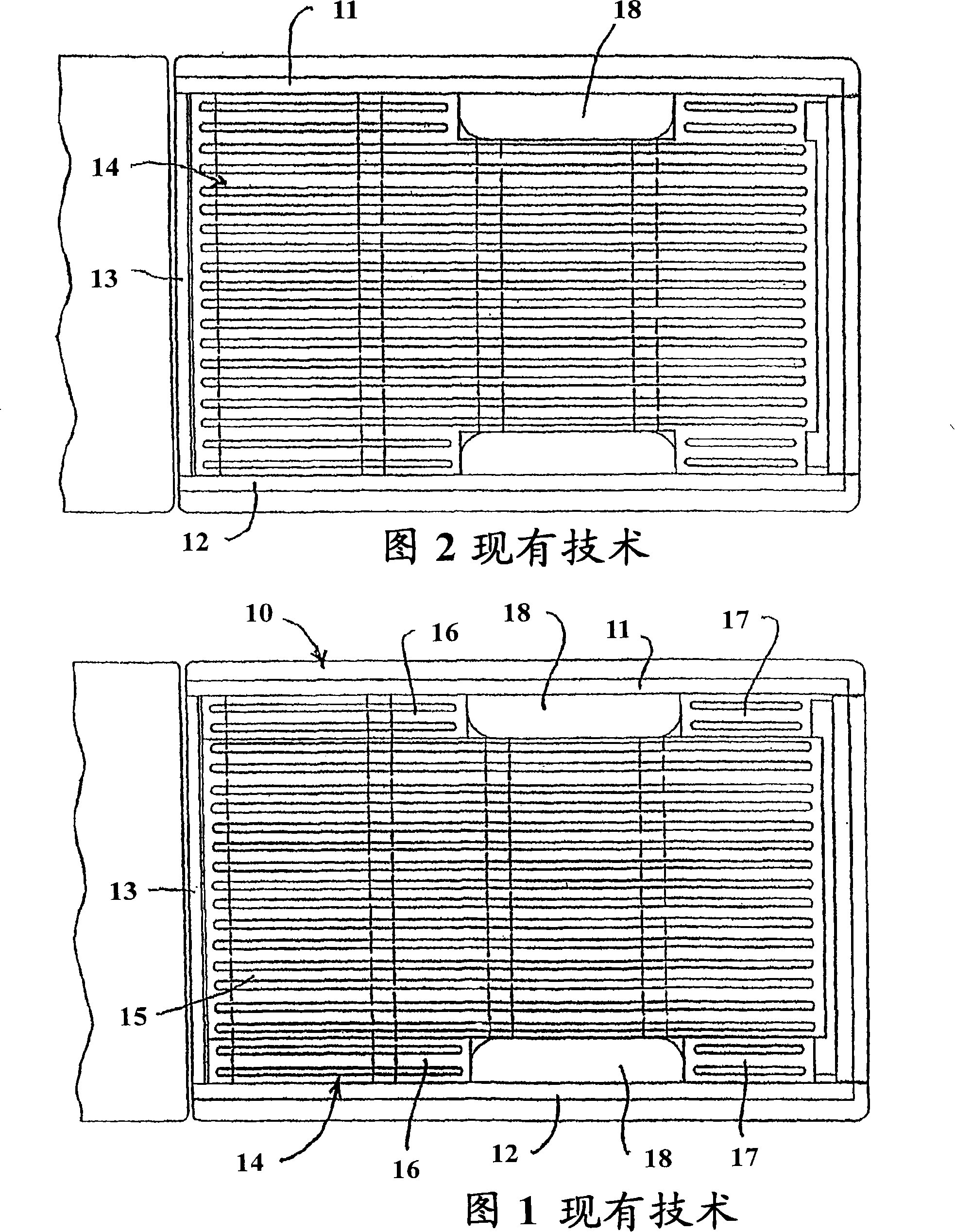

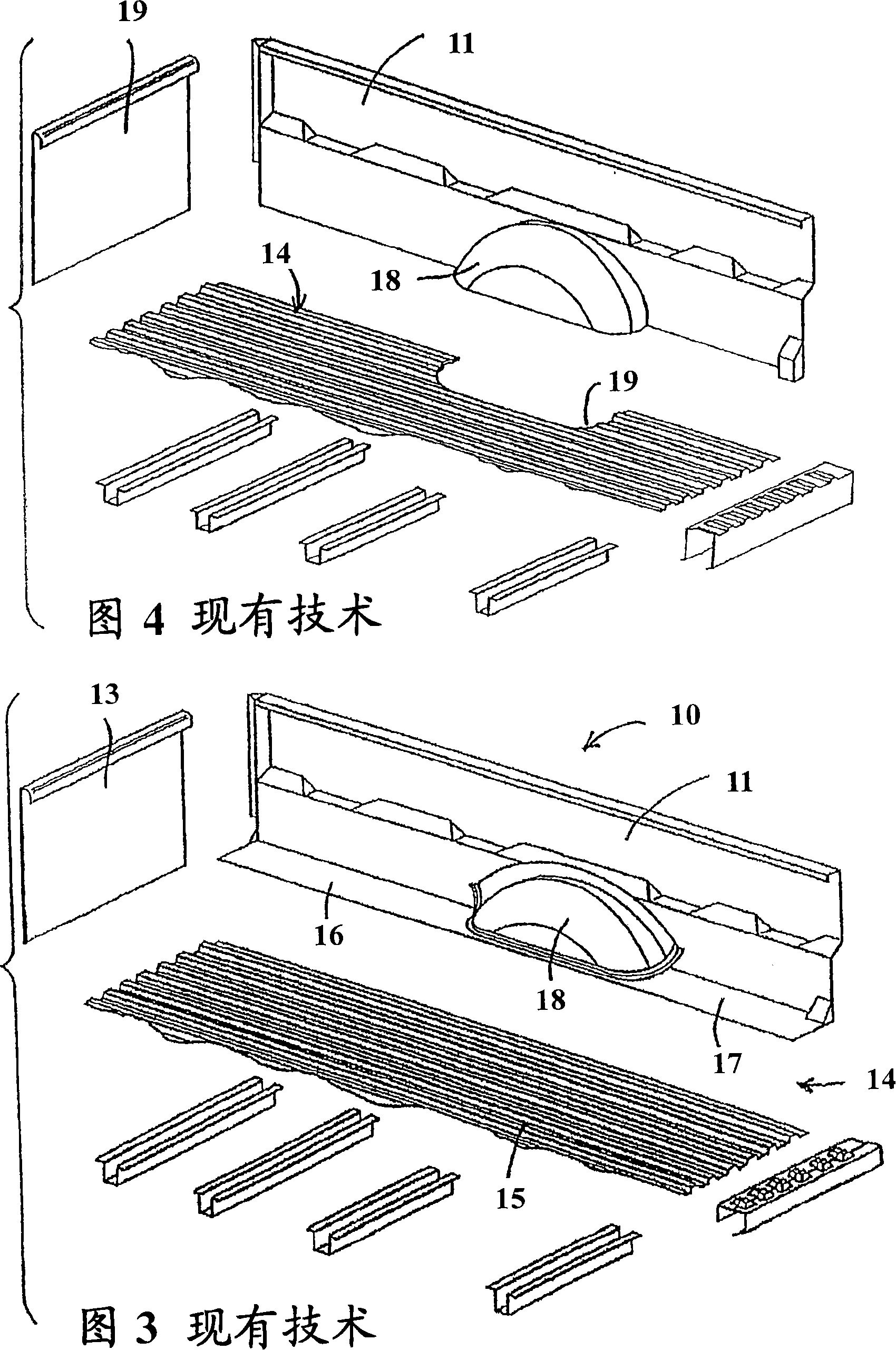

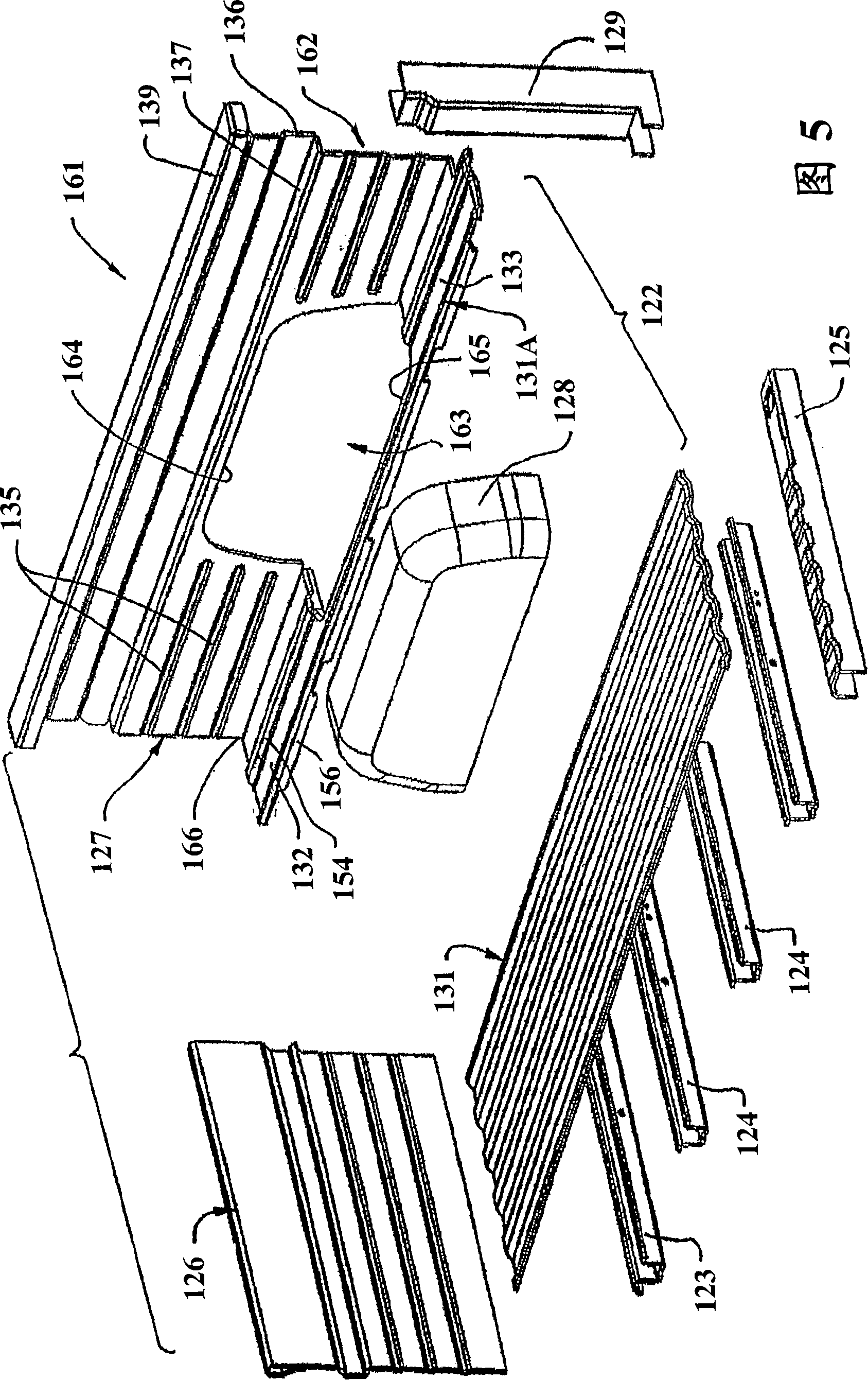

[0032] Referring to Figure 5, there is shown one embodiment of an improved automobile bed assembly 161, particularly a light truck bed assembly, wherein a roll formed quarter Plate 162 (ie, a one-piece bottom / side plate). Only the bottom / side panel 162 on the right is shown in FIG. / Mirror image of the side panel.

[0033] The bed assembly 161 includes a floor (also referred to as a floor) 122 supported on an underlying plurality of beams, such as a front beam 123 , a number of intermediate beams 124 , and a rear beam 125 . An upstanding front panel 126 protrudes upwardly near the front edge of the bottom panel 122, side panels 127 protrude upwardly near each side of the bottom panel, and a wheel well housing 128 is fitted on each side panel 127 and the corresponding side of the bottom panel 122 between the side parts. The rear edges of the side panels engage uprights or struts 129 .

[0034] In the carriage assembly 161, the floor 122 is made up of a plurality of floor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com