Flexible valve

A flexible sleeve and sleeve technology, applied in the field of flexible valves, can solve the problems of short service life of sleeve valve, return of flushing water, large sleeve strain, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

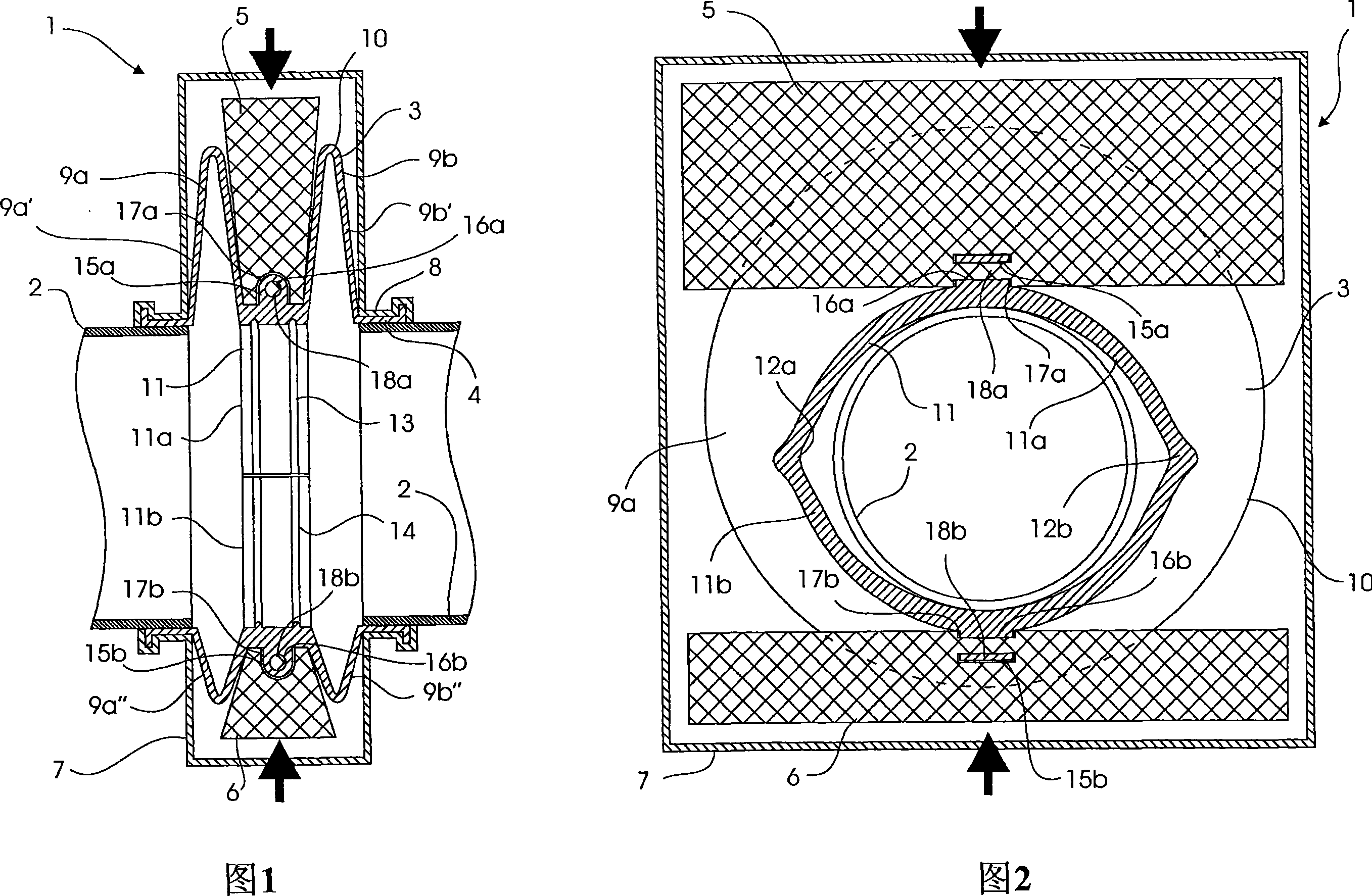

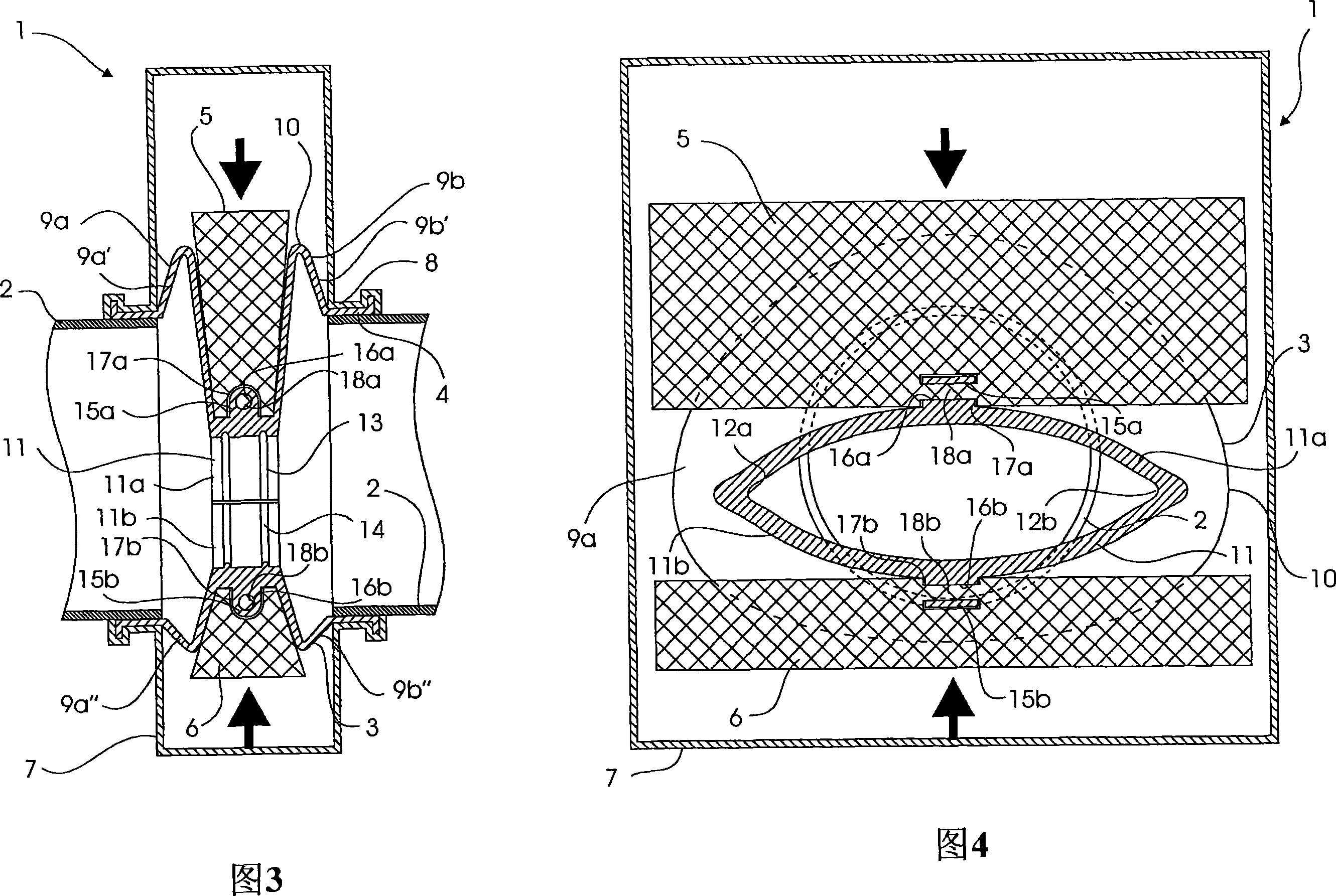

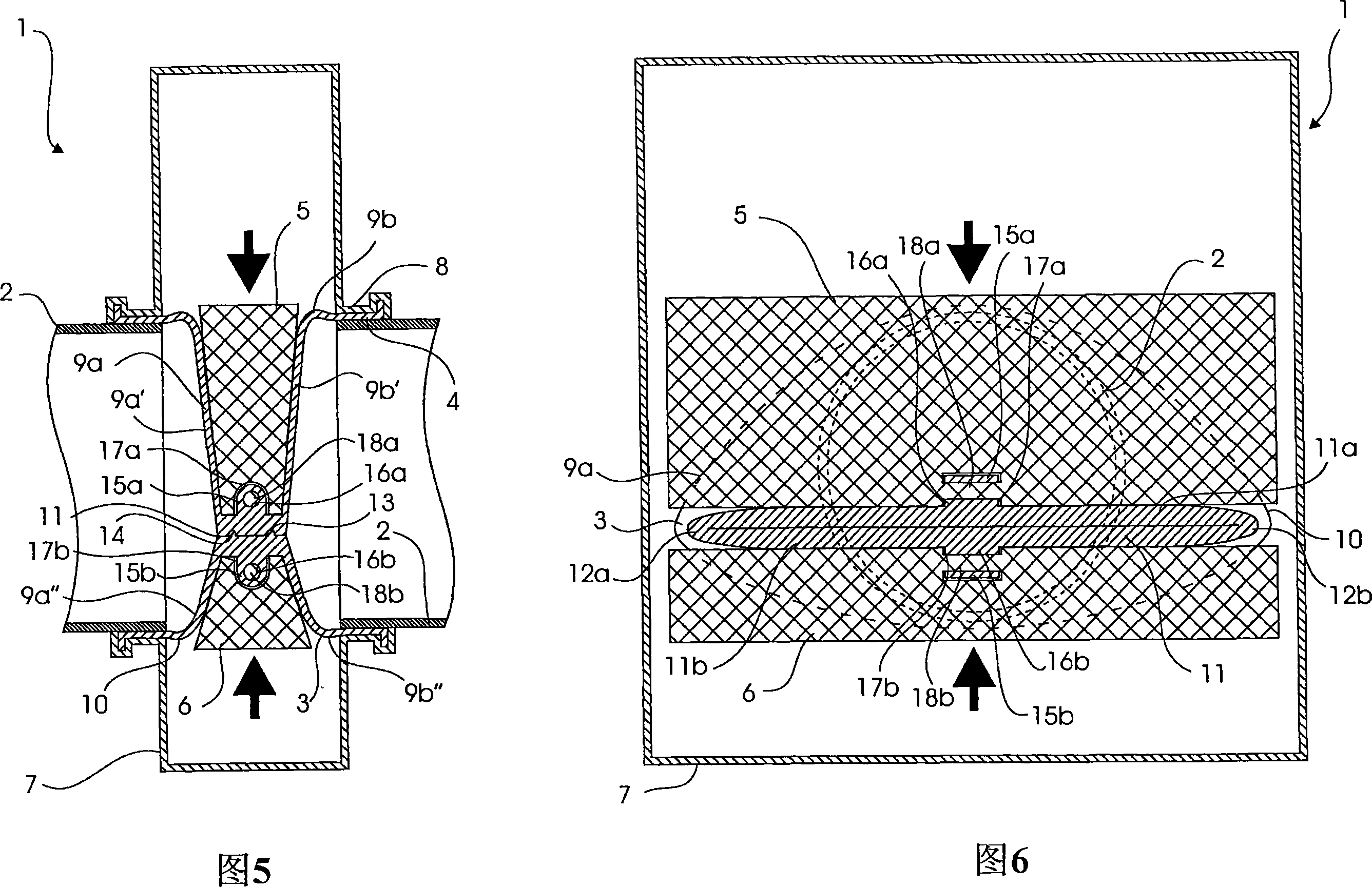

[0053] In the following it is assumed that the valve 1 according to the invention in FIGS. 1 to 6 is installed in a drain line 2 from a sanitary fitting (not shown) in a replaceable sanitary fitting module (not shown). The space available within such modules is limited, so it is important that the valves have a short built-in length and a small width in transverse direction so that the valves can fit within the modules.

[0054] The valve comprises a sleeve 3 tightly connected to a drain line 2 with a pipe connection 4, and an upper side 5 and a lower side 6 displaceable back and forth in opposite phases.

[0055] The sleeve and slide are surrounded by a closed housing 7 of the pipe connection 4 tightly connected to the sleeve by other pipe connections 8 .

[0056] The sleeve is formed with two circumferential folds 9a and 9b with an upper part 9a', 9b' and a lower part 9a", 9b". Seen in axial section, the fold in this case is mainly shaped as a V with an apex angle in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com