Agricultural material impact test device and method

An impact test and material technology, which is applied in the direction of testing the strength of materials by using one-time impact force, can solve the problems that the method has not been reported, and the impact process of single grain material and threshing element cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

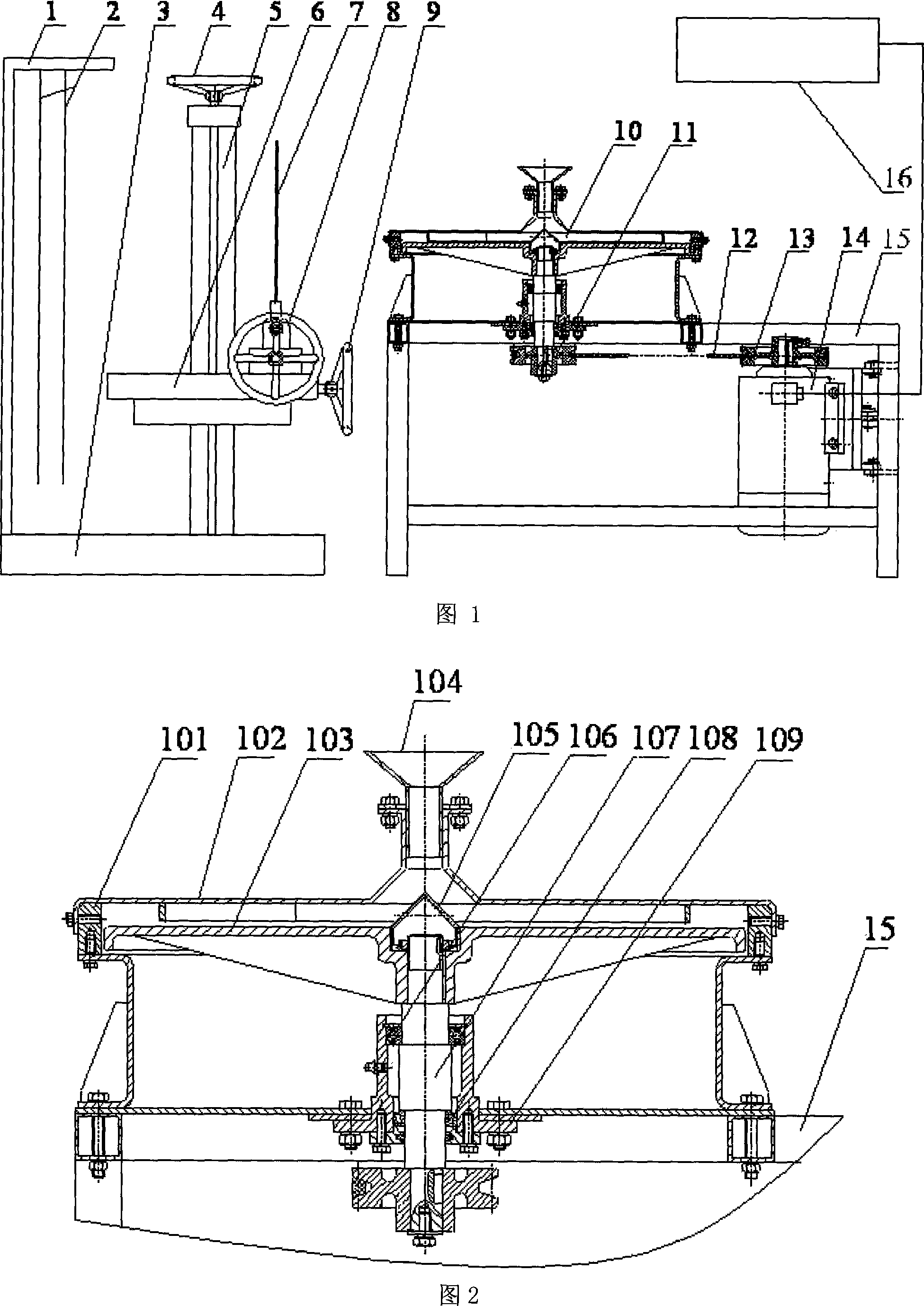

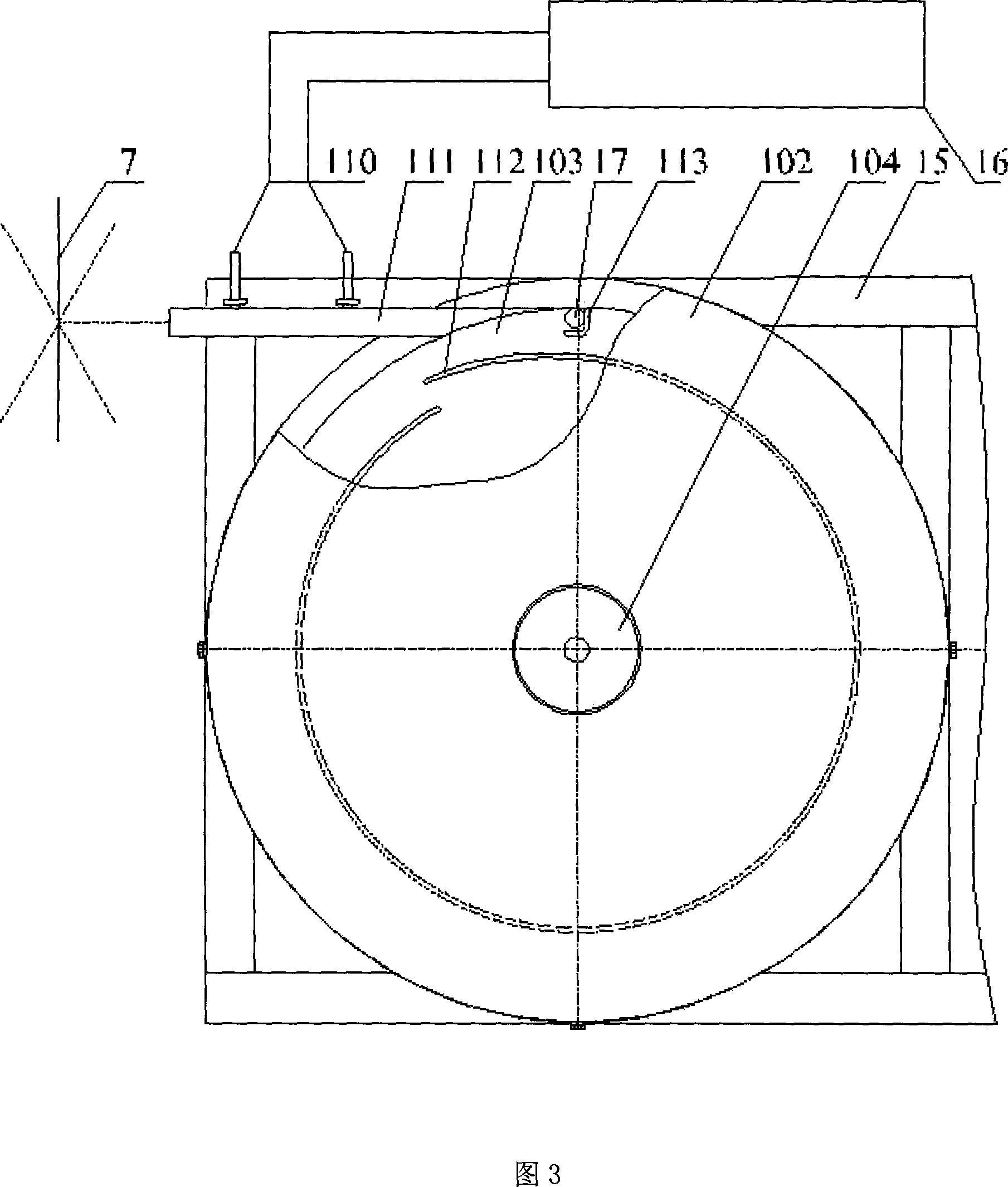

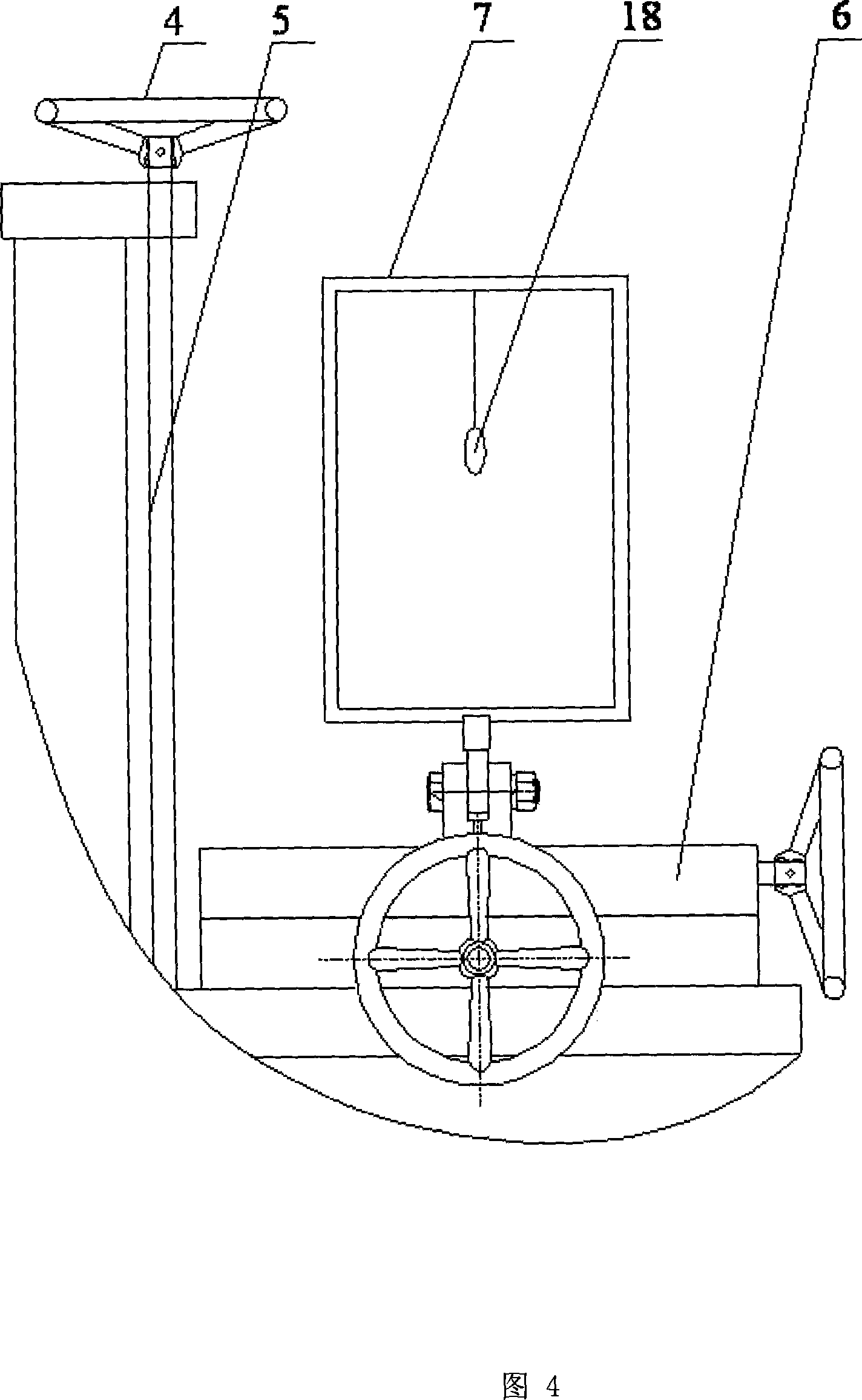

[0018] As shown in FIG. 1 , the transmitting device 10 is arranged beside the material fixing bracket 7 , and the monitoring and control system 16 is near the transmitting device 10 and the material fixing bracket 7 and connected with signal lines. The launcher 10 and the variable frequency speed regulating motor 14 are all fixed on the frame 15, the control end of the frequency variable speed regulating motor 14 is connected with the monitoring and control system 16, and the driving pulley 13 is installed on the variable frequency speed regulating motor 14 shafts. As shown in FIGS. 2 and 3 , the driven pulley 11 is installed at the position of the connecting seat 109 on the main shaft 107 , and the driving pulley 13 and the driven pulley 11 are connected by a V-belt 12 . The power is input by the frequency conversion speed regulating motor 14, which drives the turntable 103 to rotate. The turntable 103 is fixed with a dial 113, the tapered end 105 is installed on the main shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com