Method for producing instant rice

A production method and technology of instant rice, applied in the fields of application, food preparation, food science, etc., can solve the problems of poor taste, difficulty in serving dishes, and high cost, and achieve the effects of simple and easy production process, no rice bran smell, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

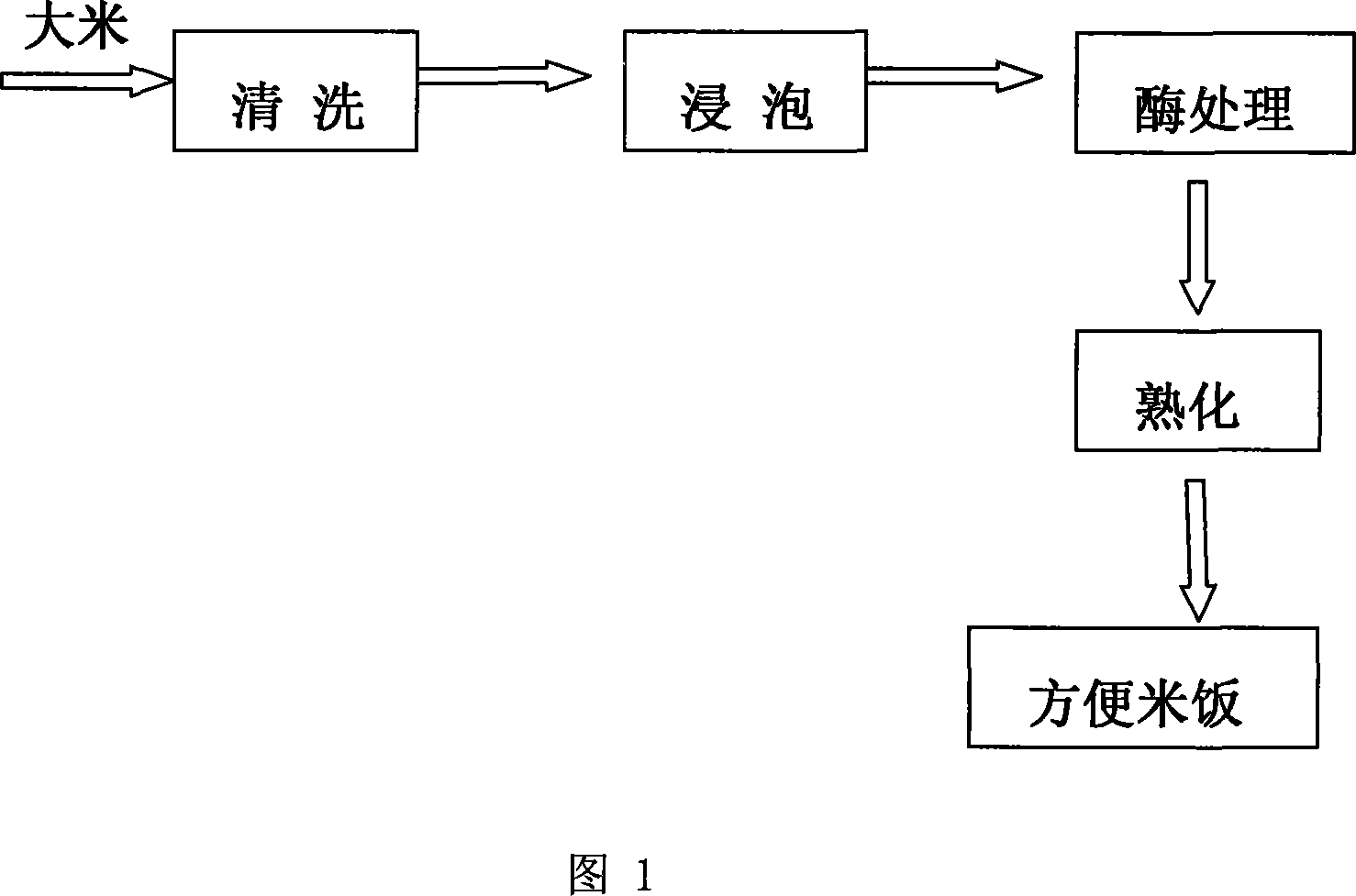

Image

Examples

Embodiment 1

[0025] 1. Cleaning

[0026] Before washing the rice, check whether the rice is moldy or has impurities such as stones and soil. Moldy rice cannot be processed into instant rice. Most of the stone and soil clods should be picked out and sifted out. Rice in stock for more than two years is not easy to process instant rice because the quality of the rice is aging. The rice cleaning equipment needs to be cleaned many times, and too much debris will flow into the next process with the rice, affecting product quality.

[0027] 2. Soak

[0028] Soak the rice in water, the water surface is submerged by about 2cm, the soaking temperature is 25°C-60°C, and the soaking time is 180 minutes.

[0029] 3. Enzyme treatment

[0030] Papain is mixed and stirred with rice, and the weight ratio of papain addition to rice is 3: 100.

[0031] 4. Ripening

[0032] Steam the rice at 90°C for 20 minutes.

Embodiment 2

[0034] 1. Cleaning

[0035] Same as Example 1

[0036] 2. Soak

[0037] Soak the rice in water, the water surface is submerged about 2cm above the rice, the soaking temperature is 60°C, and the soaking time is 30 minutes.

[0038] 3. Enzyme treatment

[0039] The rice is mixed and stirred with cellulase and pectinase, and the weight ratio of the added amount of cellulase and pectinase to the rice is 1:25.

[0040] 4. Ripening

[0041] Cook the rice at 100°C for 15 minutes.

Embodiment 3

[0043] 1. Cleaning

[0044] Same as Example 1

[0045] 2. Soak

[0046] Soak the rice in water, the water surface is submerged by about 2cm, the soaking temperature is 40°C, and the soaking time is 60 minutes.

[0047] 3. Enzyme treatment

[0048] The pectinase is mixed and stirred with the rice, and the weight ratio of the added amount of the pectinase to the rice is 1:35.

[0049] 4. Ripening

[0050] Steam the rice at 95°C for 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com